Reinforced nitrogen and phosphorus removal method suitable for reclaimed water with low carbon nitrogen ratio

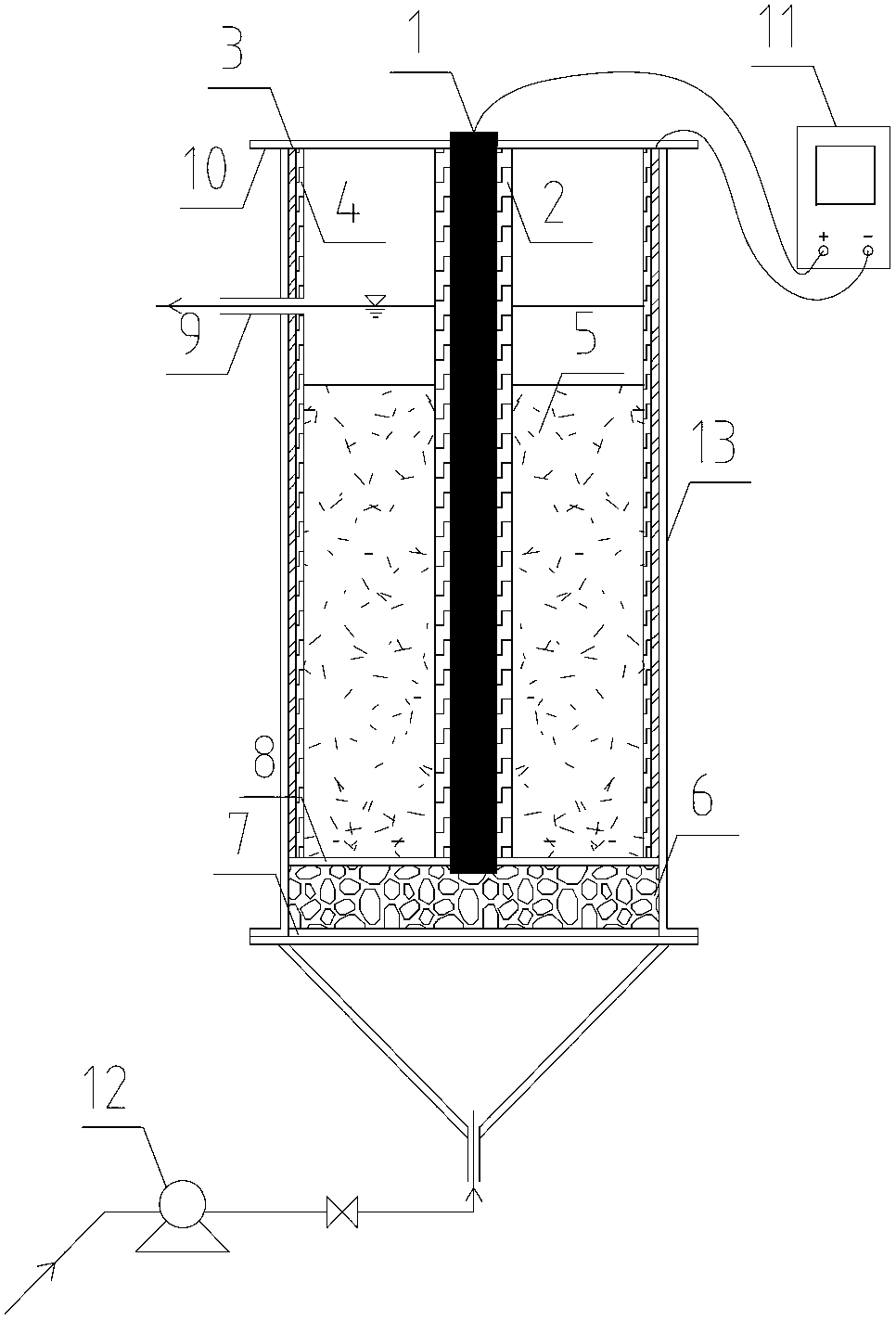

A technology for denitrification and phosphorus removal and low carbon to nitrogen ratio, applied in the field of environmental engineering, can solve problems such as insufficient hydrogen production by corrosion, and achieve the effects of enhancing the process of autotrophic denitrification and denitrification, promoting growth metabolism, and increasing inorganic carbon sources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

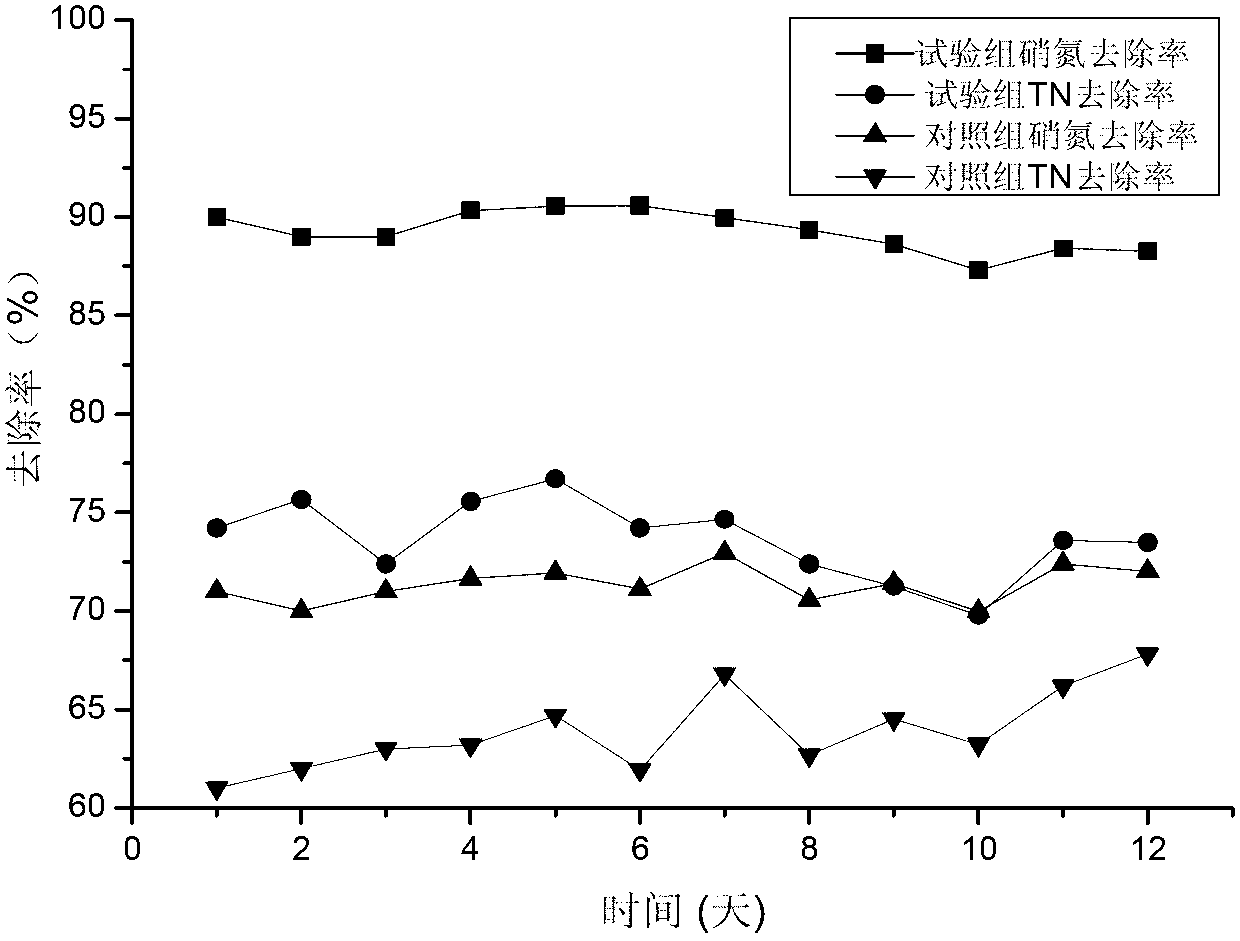

[0025] Direct treatment pH=7, COD=45mg / L, NO 3 - -N=30mg / L,H 2 PO 4 - -P=1.5mg / L artificial water distribution to simulate the water quality of reclaimed water. Control the hydraulic retention time to 10h, the current intensity to 40mA, and the temperature to 15°C. Influent water enters from the bottom of the reactor, passes through the limestone supporting layer and flows evenly into the main reaction area, and exits from the outlet on the upper part of the reactor. In this way, the experimental group effluent NO 3 - -N=3.84mg / L, TN=8.70mg / L, COD=10mg / L, TP is less than 0.3mg / L. The removal rate of nitrate nitrogen in the test group was about 16%-18% higher than that of the control group, and the removal rate of TN was about 8%-14% higher than that of the control group.

Embodiment 2

[0027] Direct treatment pH=7, COD=45mg / L, NO 3 - -N=30mg / L,H 2 PO 4 --P=1.5mg / L artificial water distribution to simulate the water quality of reclaimed water. Control the hydraulic retention time to 10h, the current intensity to 60mA, and the temperature to 15°C. Influent water enters from the bottom of the reactor, passes through the limestone supporting layer and flows evenly into the main reaction area, and exits from the outlet on the upper part of the reactor. In this way, the experimental group effluent NO 3 - -N=2.65mg / L, TN=5.90mg / L, COD=10mg / L, TP is less than 0.3mg / L. The removal rate of nitrate nitrogen in the test group was about 16%-18% higher than that of the control group, and the removal rate of TN was about 10%-12% higher than that of the control group.

Embodiment approach

[0028] In the above two implementations, the application of sponge iron and activated carbon composite fillers in the three-dimensional electrode biofilm process can strengthen the removal of nitrogen and phosphorus in the low carbon-to-nitrogen ratio reclaimed water. Compared with the three-dimensional electrode biofilm reactor only filled with activated carbon filler in the comparative test under the same conditions, the efficiency of nitrogen and phosphorus removal has been greatly improved. The effect is obvious.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com