Composite membrane for mabr and preparation method thereof

A technology for composite membranes and porous membranes, applied in the field of composite membranes and preparations for MABR, can solve problems such as easy pollution, expensive equipment, and difficulty in obtaining uniform reactions, and achieve low production costs, easy control, and simple preparation methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The invention provides a composite membrane for MABR and a preparation method thereof. The surface of the porous membrane is evenly coated with levodopa, and a layer of levodopa composite membrane is formed on the surface of the membrane. The thickness of the levodopa composite membrane is 10 nanometers to 2 mm, to obtain higher membrane bubble point pressure, membrane oxygen permeability, surface hydrophilicity and surface roughness, etc.

[0031] The porous membrane used in the present invention includes polyethylene, polytetrafluoroethylene, polyvinylidene fluoride, polypropylene, polystyrene, polyacetic cellulose, polyvinyl acetate cellulose, polyvinyl chloride, polysulfone, polyethersulfone, etc. Polymer materials and their modification, composite tubular membranes (including hollow fiber membranes, etc.) and flat membranes. Porous membranes that can be treated in the present invention include tubular membranes and flat sheet membranes.

[0032] In the present inv...

Embodiment 1

[0041] A composite membrane for MABR, the membrane provided by this embodiment is a composite membrane formed by applying a levodopa solution to the surface of a PVDF porous hollow fiber membrane;

[0042] The specific preparation method is as follows:

[0043] (1) Preparation of levodopa solution: prepare 500 milliliters of levodopa solution with a pH value of 10 and a concentration of 0.8 g / L;

[0044] (2) Coating: Coat it evenly and without defects on the surface of PVDF porous hollow fiber membrane;

[0045] (3) Heat treatment: heat treatment at 80°C for 10 hours.

[0046] After testing, the gas flux is changed from 0.26mL / (S*mm before unmodification 2 ) to 0.34mL / (S*mm 2 ), the water contact angle decreased from 86.5 degrees to 76.2 degrees.

Embodiment 2

[0048]A composite membrane for MABR. The membrane provided in this embodiment is a composite membrane formed by coating a levodopa solution on the surface of a polysulfone porous flat membrane.

[0049] The specific preparation method is as follows:

[0050] (1) Preparation of levodopa solution: prepare a levodopa solution with a pH value of 5.0 and a concentration of 0.1 g / L;

[0051] (2) Coating: apply it evenly and without defects on the surface of polysulfone membrane;

[0052] (3) Heat treatment: heat treatment at 30°C for 30 hours.

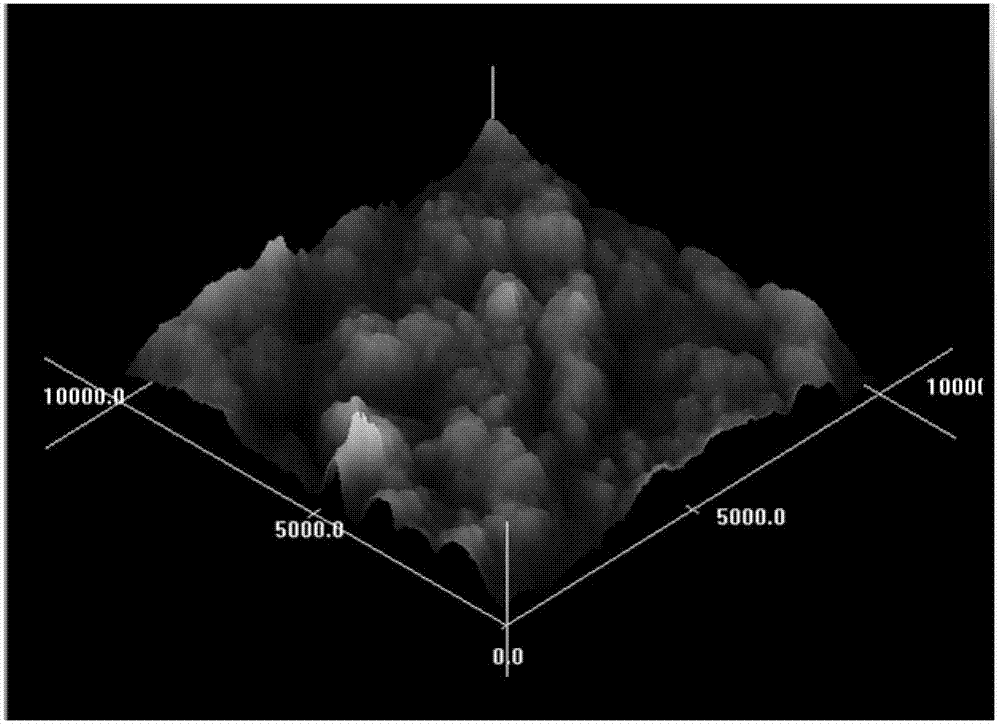

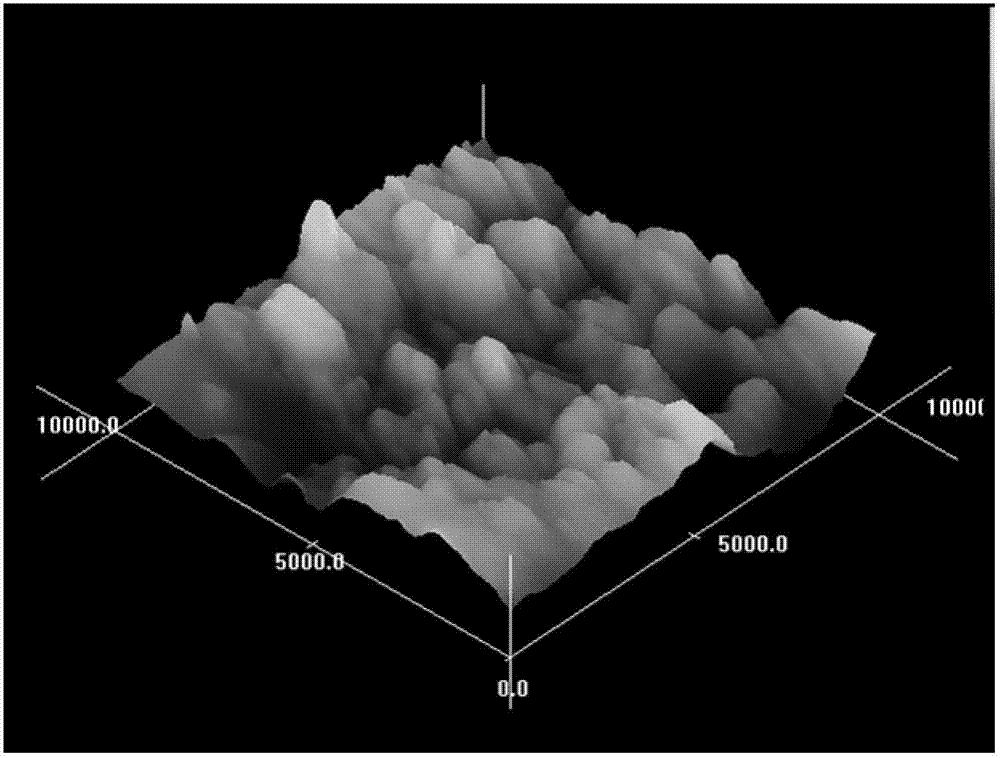

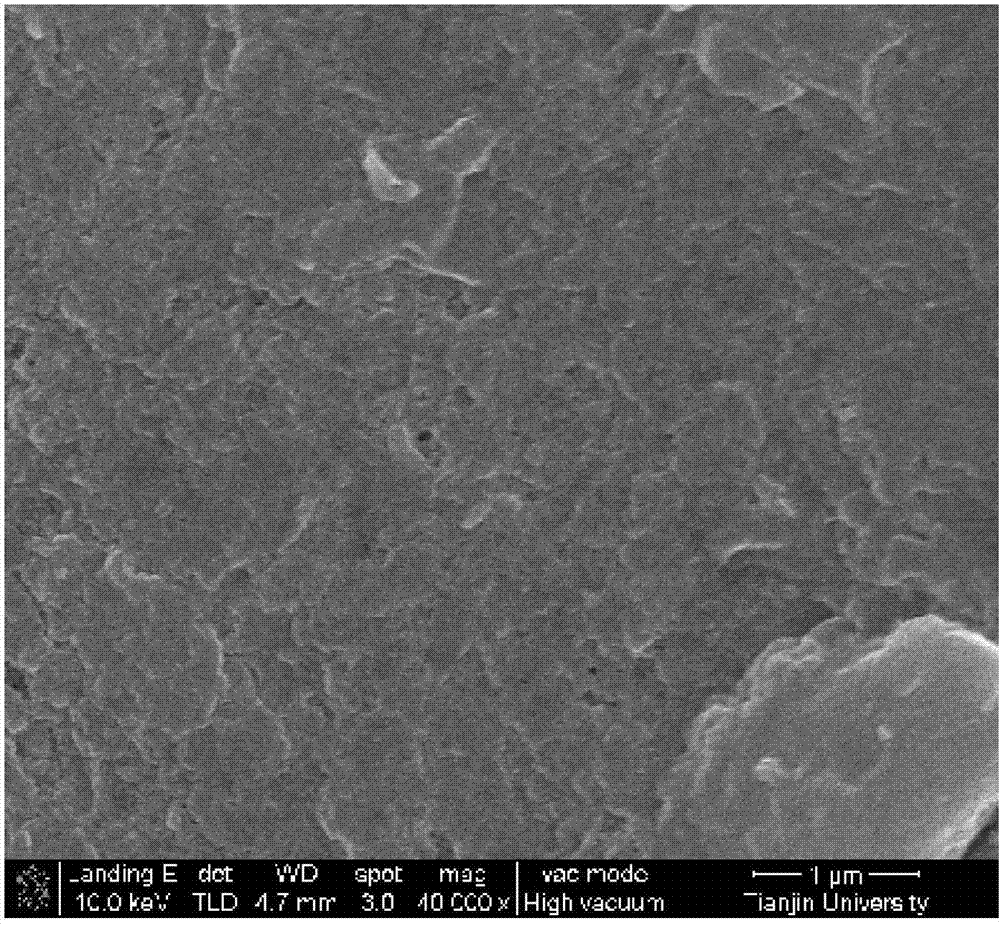

[0053] After testing, the gas flux is changed from 0.31mL / (S*mm before unmodification 2 ) to 0.54mL / (S*mm 2 ), the water contact angle decreased from the original 76.5 degrees to 66.2 degrees, and the root mean square roughness of the film surface increased from the original 88.030nm to 111.777nm. Scanning electron micrographs of the membrane surface before modification are shown in figure 1 , the scanning electron micrographs of the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com