Raw material used for sound equipment vibrating plate and preparation method thereof

A technology of audio equipment and vibration plate, applied in the direction of sensors, electrical components, diaphragm structures, etc., can solve the problem of difficult to reflect the customer's acoustic characteristics, and achieve the effect of improving the acoustic characteristics and improving the defect rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] A raw material for an acoustic device vibration plate that laminates a polymer film and thermoplastic polyurethane according to an embodiment of the present invention for achieving the above-mentioned problem is characterized in that a polymer film and thermoplastic polyurethane are supplied to a laminating device and laminated. The multi-layer composite film is suitable for the raw material of the vibration plate for the loudspeaker.

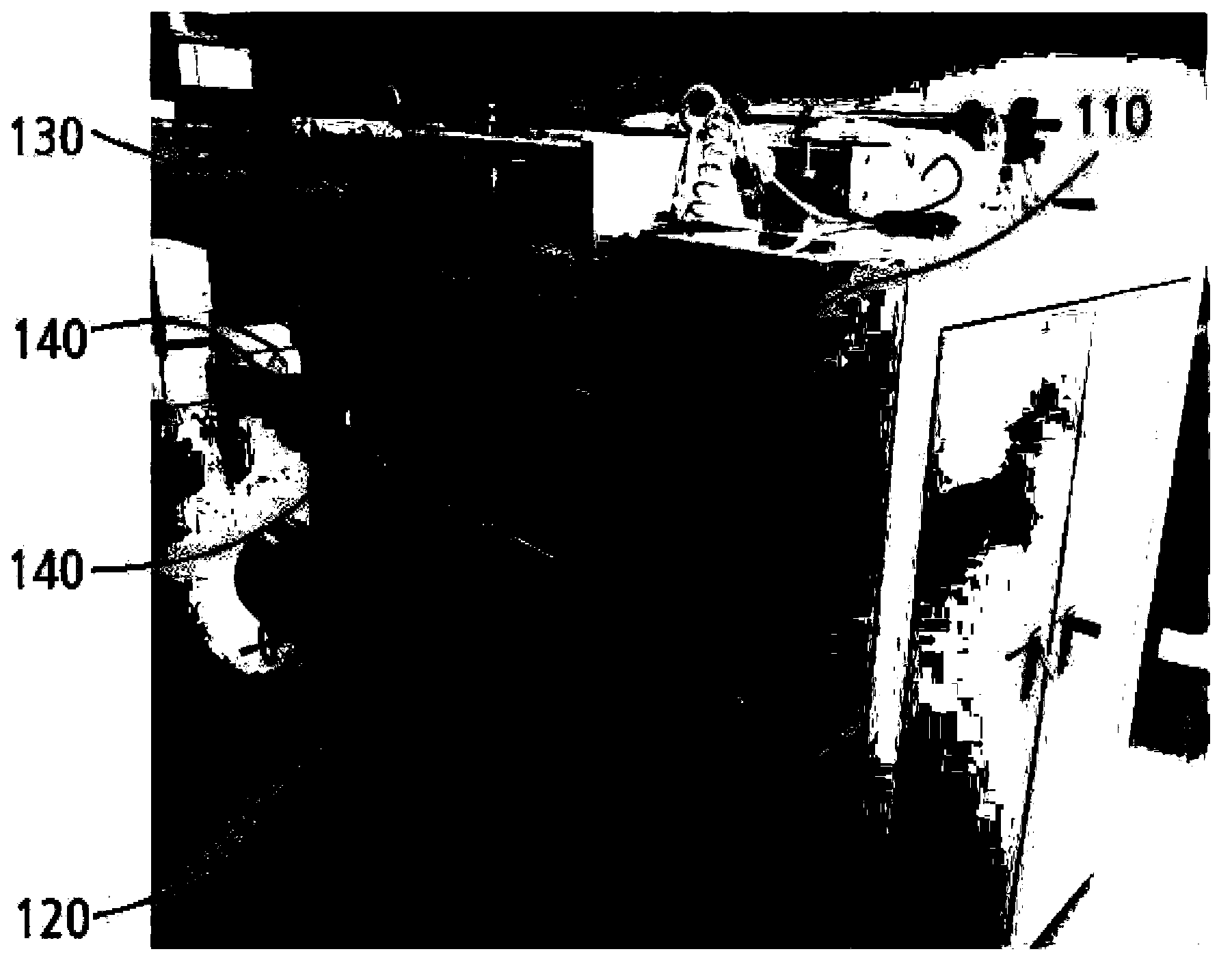

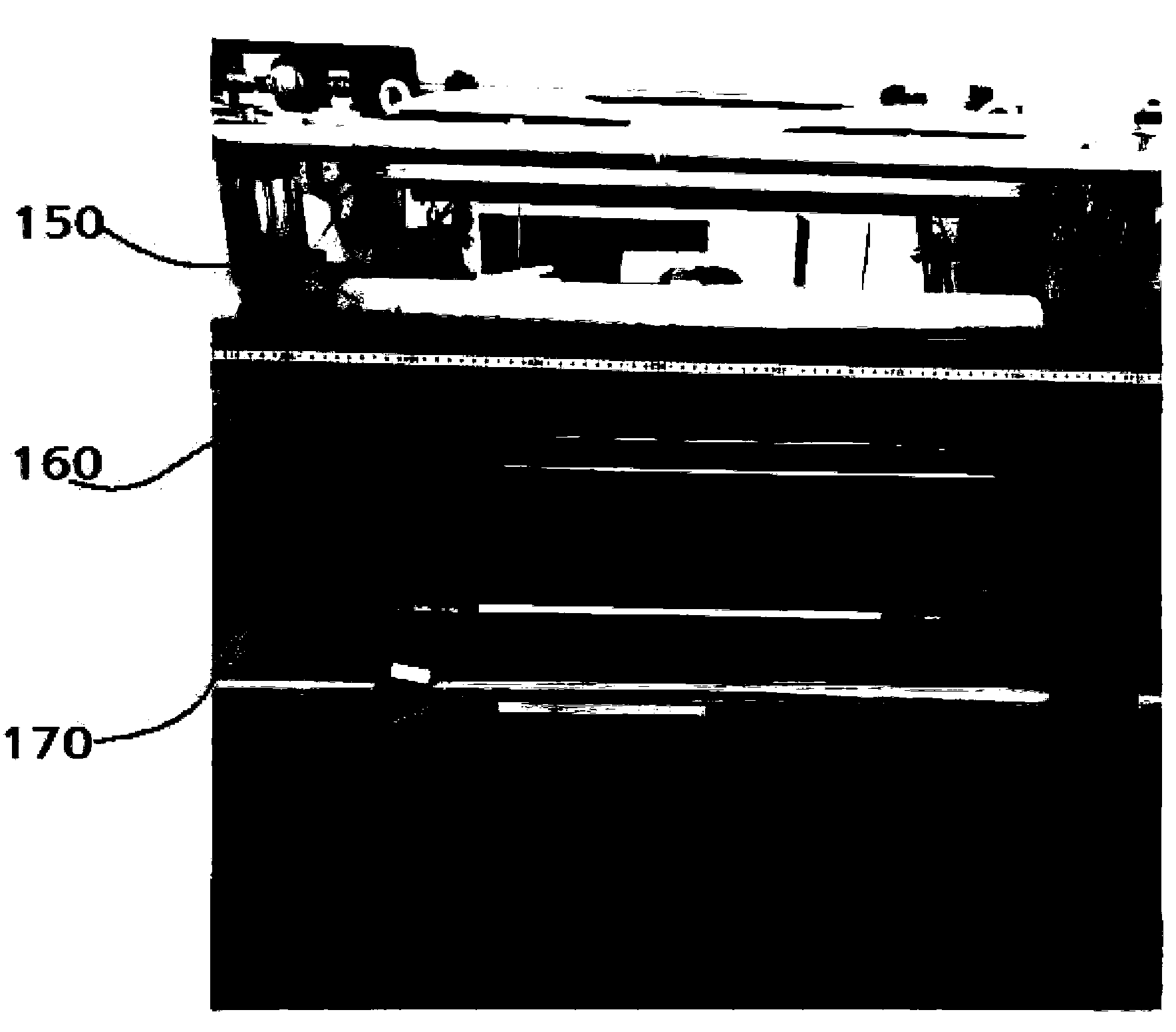

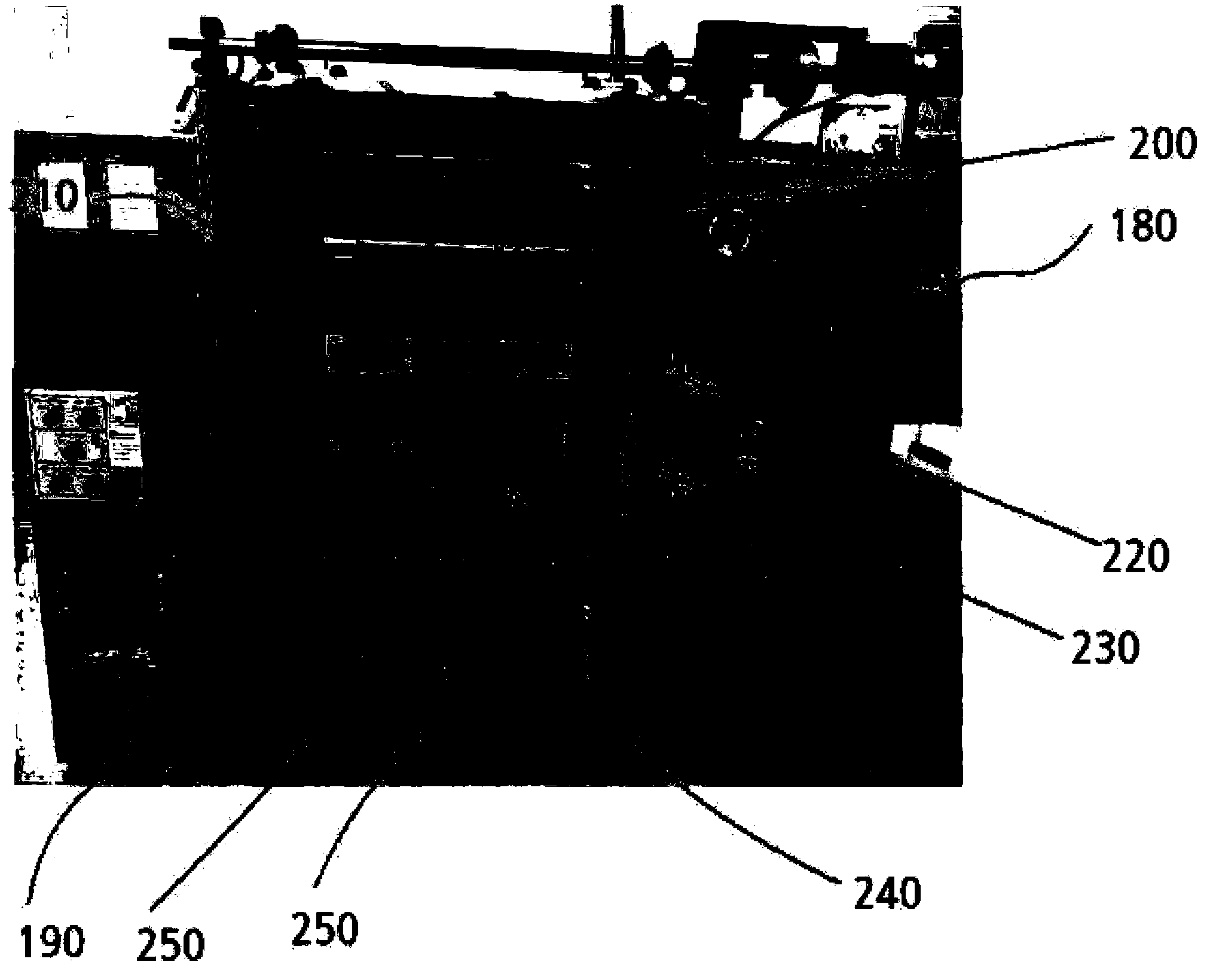

[0041] The present invention is characterized in that the above lamination device includes: a front control panel 110 for adjusting the break value of the film and thermoplastic polyurethane; a film shaft 120 formed on the lower side of the front part (injection part) , for installing and putting in the polymer film; thermoplastic polyurethane shaft 130, which is formed on the upper side of the front part (injection part), for installing and putting in thermoplastic polyurethane; guide roller 140, which is arranged on the above-mentioned ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com