Method for heating oil shale underground in situ

一种油页岩、原位的技术,应用在油页岩地下原位加热领域,达到避免有毒导电材料、减少施工量的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

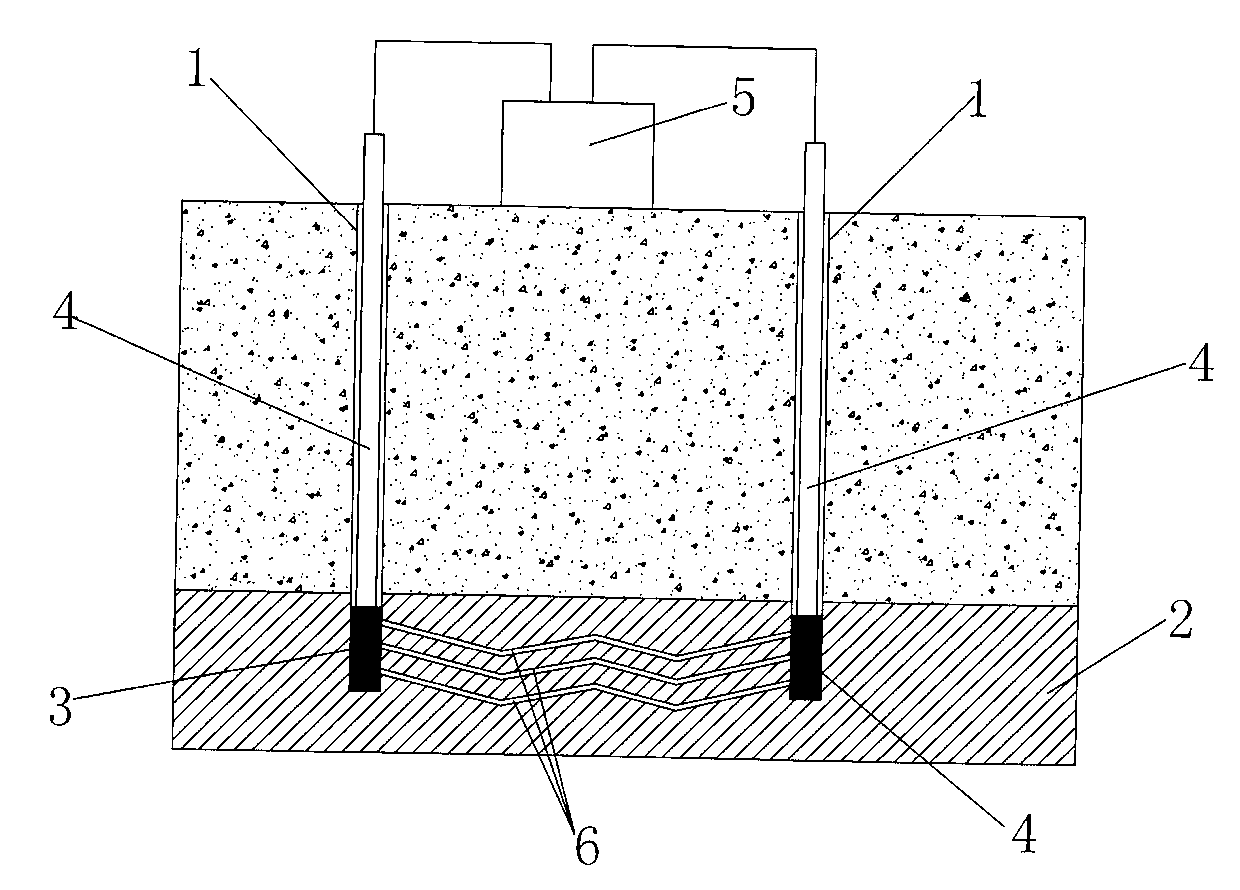

Image

Examples

Embodiment 1

[0023] The experiment was carried out with oil shale samples in the laboratory, and the distance between the electrodes was 50cm. Before the experiment started, the resistance between the electrodes was measured as 250K ohms. During the experiment, an alternating current with a frequency of 50 Hz and a peak voltage of 5 KV was first applied to the electrodes. By visual observation, it can be found that partial discharge phenomenon occurs at this voltage. The power consumption of the power supply is about 300W. This process lasts 30 minutes. During these 30 minutes, a plasma channel of electrothermal breakdown gradually formed. The resistance between the electrodes became 800 ohms. Subsequently, a current with a frequency of 50 Hz will pass between the electrodes, and the resistance heating effect of the low-resistance channel will be used for heating. The guaranteed power is 1KW, and the voltage is also reduced to 100V.

Embodiment 2

[0025] In the laboratory, the lignite sample was used for the experiment, and the distance between the electrodes was 45cm. Before the experiment, the resistance between the electrodes was measured as 150K ohms. At the beginning of the experiment, an alternating current with a frequency of 50 Hz and a peak voltage of 8 KV was first applied to the electrodes. By visual observation, it can be found that partial discharge phenomenon occurs at this voltage. The power consumption of the power supply is about 600W. This process lasts 15 minutes. During these 15 minutes, a plasma channel of electrothermal breakdown gradually formed. The resistance between the electrodes became 300 ohms. Subsequently, a current with a frequency of 50 Hz will pass between the electrodes, using the resistance heating effect of the low-resistance channel for heating. At the beginning, the voltage is hundreds of volts. , In order to ensure that the power is 1KW, the voltage is also reduced to 60V.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com