Method for recovery germanium from germanium-containing flue dust

A germanium fume and obtained technology, applied in the field of germanium recovery, can solve the problems of low germanium recovery rate, long process flow, environmental pollution, etc., and achieve the effects of high recovery rate, simplified process process, and reduced production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

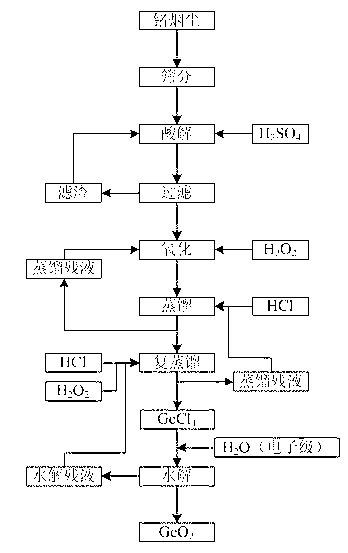

Image

Examples

Embodiment 1

[0029] (1) Crush and sieve 500g of germanium dust containing 0.05% Ge to -200 mesh;

[0030] (2) According to the liquid-solid ratio (L / kg) of 0.5:1, stir and mix the water and the germanium dust obtained in step (1) evenly;

[0031] (3) In the mixture obtained in step (2), add industrial sulfuric acid with a mass concentration of 80% according to the liquid-solid ratio (L / kg) of acid to germanium fumes of 2.5:1, and keep stirring at 90°C for 2 hours until until no more gas is produced in the slurry;

[0032] (4) Under the condition of stirring at 60°C, press H 2 o 2 The liquid-solid ratio (L / kg) to germanium fumes is 1:1. Add H with a mass concentration of 50% to the slurry obtained in step (3) at a speed of 1L / min. 2 o 2 , the adding time is controlled at 0.8h until H 2 o 2 Complete decomposition without bubbles;

[0033] (5) Filter the slurry obtained in step (4), add industrial hydrochloric acid with a mass concentration of 70% to the filtered clear liquid according...

Embodiment 2

[0036] (1) Crush and sieve germanium dust to -200 mesh;

[0037] (2) According to the liquid-solid ratio (L / kg) of 0.8:1, stir and mix the water and the germanium dust obtained in step (1) evenly;

[0038] (3) In the mixture obtained in step (2), add industrial sulfuric acid with a mass concentration of 70% according to the liquid-solid ratio (L / kg) of acid to germanium fumes of 2:1, and continue stirring at 88°C for 2.5h until Until no more gas is produced in the slurry;

[0039] (4) Under the condition of stirring at 50°C, press H 2 o 2 The liquid-solid ratio (L / kg) to germanium fumes is 0.8:1. Add H with a mass concentration of 40% to the slurry obtained in step (3) at a speed of 1.1 L / min. 2 o 2 , the addition time is controlled at 0.5h until H 2 o 2 Complete decomposition without bubbles;

[0040] (5) Filter the slurry obtained in step (4), and add industrial hydrochloric acid with a mass concentration of 60% to the filtered clear liquid according to the liquid-sol...

Embodiment 3

[0043] (1) Crush and sieve germanium dust to -200 mesh;

[0044] (2) According to the liquid-solid ratio (L / kg) of 1:1, stir and mix the water and the germanium dust obtained in step (1) evenly;

[0045] (3) In the mixture obtained in step (2), add industrial sulfuric acid with a mass concentration of 50% according to the liquid-solid ratio (L / kg) of acid to germanium fumes of 1.5:1, and continue stirring at 85°C for 2.2h until Until no more gas is produced in the slurry;

[0046] (4) Under the condition of stirring at 70°C, press H 2 o 2 The liquid-solid ratio (L / kg) to germanium fumes is 0.5:1. Add H with a mass concentration of 30% to the slurry obtained in step (3) at a speed of 1.2 L / min. 2 o 2 , the addition time is controlled at 1h until H2 o 2 Complete decomposition without bubbles;

[0047] (5) Filter the slurry obtained in step (4), and add industrial hydrochloric acid with a mass concentration of 45% to the filtered clear liquid according to the liquid-solid r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com