High-temperature biological heap leaching method of primary copper sulphide ores

A technology for copper sulfide ore and biological heap, which is applied in the direction of improving process efficiency and can solve problems such as low sulfide content and ore heap maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

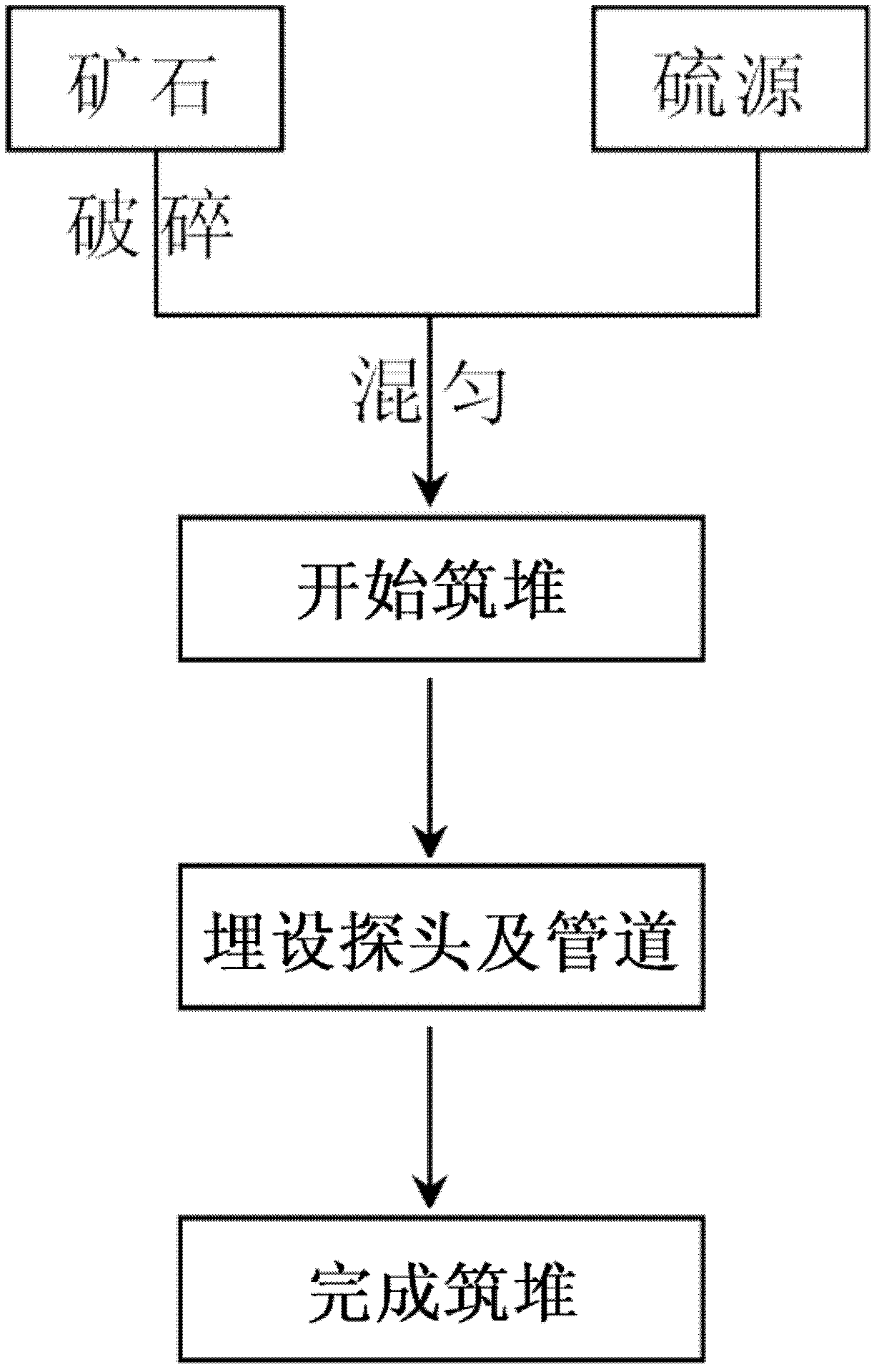

Method used

Image

Examples

Embodiment 1

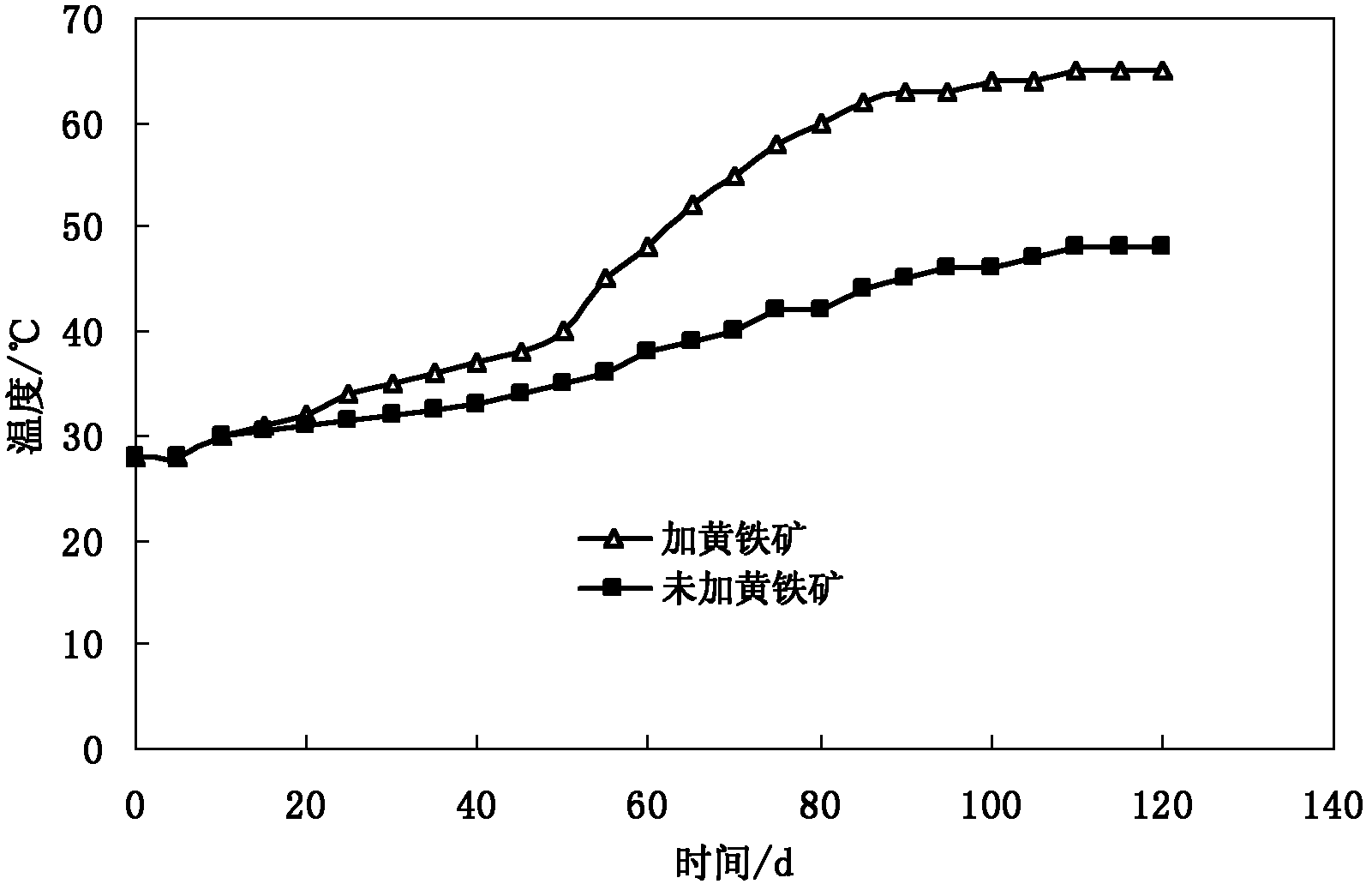

[0041] The main copper mineral in Dexing Copper Mine is primary copper sulfide ore with an occupancy of about 73wt%, secondary copper sulfide ore with an occupancy of about 14wt%, and copper oxide ore with an occupancy of about 13wt%. In the primary copper sulfide ore, the total copper content is 0.35wt%, and the sulfur content is 1.57wt%. The sulfur in the ore mainly exists in the form of pyrite, chalcopyrite and chalcocite, and the content of pyrite is It is 2.76wt%. The gangue minerals in the primary copper sulfide ore account for more than 85 wt%, mainly quartz, kaolin and the like.

[0042] (1) Acquisition of sulfur source

[0043] Buy pyrite from the market as a sulfur source, the sulfur grade is 40wt%, 150 yuan per ton.

[0044] (2) Acquisition of microorganisms

[0045] After obtaining the microorganism Acidianus brierleyi Retech-HB1 (the microorganism is preserved in the China Center for Type Culture Collection, the preservation number is CCTCC No: M209084), add De...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com