Pectinase producing bacterial strain and application in preparation of peeled citrous complex enzyme

A technology of decapsulation compound enzyme and pectinase, which is applied in the direction of enzyme, lyase, hydrolase, etc., can solve the problem of high process cost, achieve stable application, solve the effect of high cost of enzyme, and promote substitution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The strains described in the present invention were screened according to methods known in the art, and a strain of Asperillus niger WZW001 with high pectinase-producing activity and complete enzyme system was obtained, CCTCC No: M2012399.

[0046] Aspergillus niger WZW001 was grown and preserved in PDA medium (test tube slant and eggplant bottle slant), and the enzyme production ability of the strain was stable for more than 6 generations on the slant medium.

[0047] The fermentation process of the present invention is from inclined plane to seed culture medium to 5L fermenter. The strain grows in the inclined plane for 72 hours and matures, and the mature spores are dense and dark brown. Add sterile saline to make spore suspension (1~3×10 7 each / mL), inoculate the seed medium according to the inoculation amount of 5% (v / v), the seed medium formula (100mL): orange peel powder 1g, bran 1g, glucose 2g, ammonium sulfate 1g, MgSO 4 0.05g, before sterilization, adjust th...

Embodiment 2

[0055] Select the citrus decapsulation compound enzyme 1. prepared in example 1 for use in this instance, and the citrus that adopts is Zhejiang Wenzhou Tangerine. The enzyme activities of PL, PE, Exo-PG and FPA prepared by citrus decapsulation complex enzyme ① were 170U, 2400U, 0.83×10 5 U and 1.5×10 4 U enzyme solution 5400mL, adjust the pH value to 3.5 with 2mol / L hydrochloric acid. Fresh Wenzhou tangerines were washed, peeled, and split to obtain 3.6 kg of orange petals, which were completely submerged in the enzyme solution for constant temperature enzymolysis. The study found that after 78 minutes, the enzymatic hydrolysis was completed, and the orange complex and capsule coat on the surface of the orange petals were completely removed. Separate the orange petals from the enzyme liquid, wash the orange petals twice with clean water to remove the residual enzyme liquid, recover the enzyme liquid and continue to use it for the next batch of decapsulation treatment, the e...

Embodiment 3

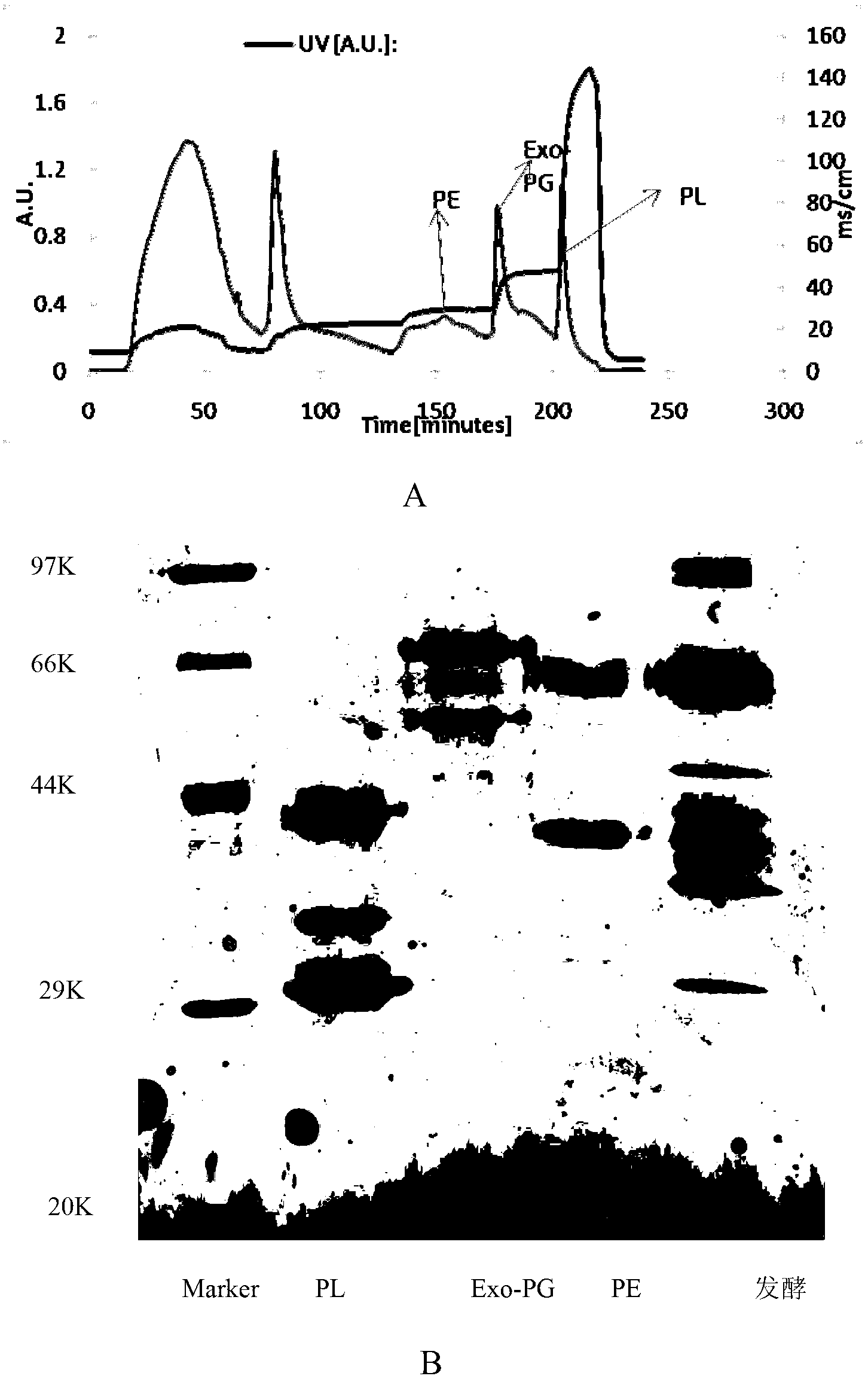

[0057] This example prepares Aspergillus niger WZW001 fermentation broth according to the method of Example 1. After the fermentation broth is filtered through four layers of gauze, it is centrifuged at a high speed of 10000r / min for 7min to obtain 2000mL of enzyme liquid, which is then concentrated by an ultrafiltration membrane with a molecular weight cut-offfigure 1 ) and enzyme activity assays, it was found that although the single enzyme components Exo-PG, PE, and PL still have some heteroproteins, the three have been separated and have no influence on each other, and can be used separately for compound applications.

[0058]The cellulase used in this example was purchased from Novozymes. The cellulase activity (calculated as FPA) is 1000U / g. The ratio of pectin lyase (PL) single enzyme component to cellulase is PL:FPA enzyme activity The complex enzyme of citrus decapsulation coat was obtained by compounding at 1 / 60:1. Use citrus decapsulation compound enzyme ② to prepare...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com