Smokeless environment-friendly birthday candle with color flame

A candle and flame technology, which is applied in the field of colored flame birthday candles and its preparation, can solve the problems of unguaranteed product appearance quality, difficult-to-color pigments, weakened oil absorption capacity, etc., and achieve improved inhibition of mold and other bacteria. The effect of high temperature resistance, repeated heating resistance, strength and flexibility improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] red flame candle

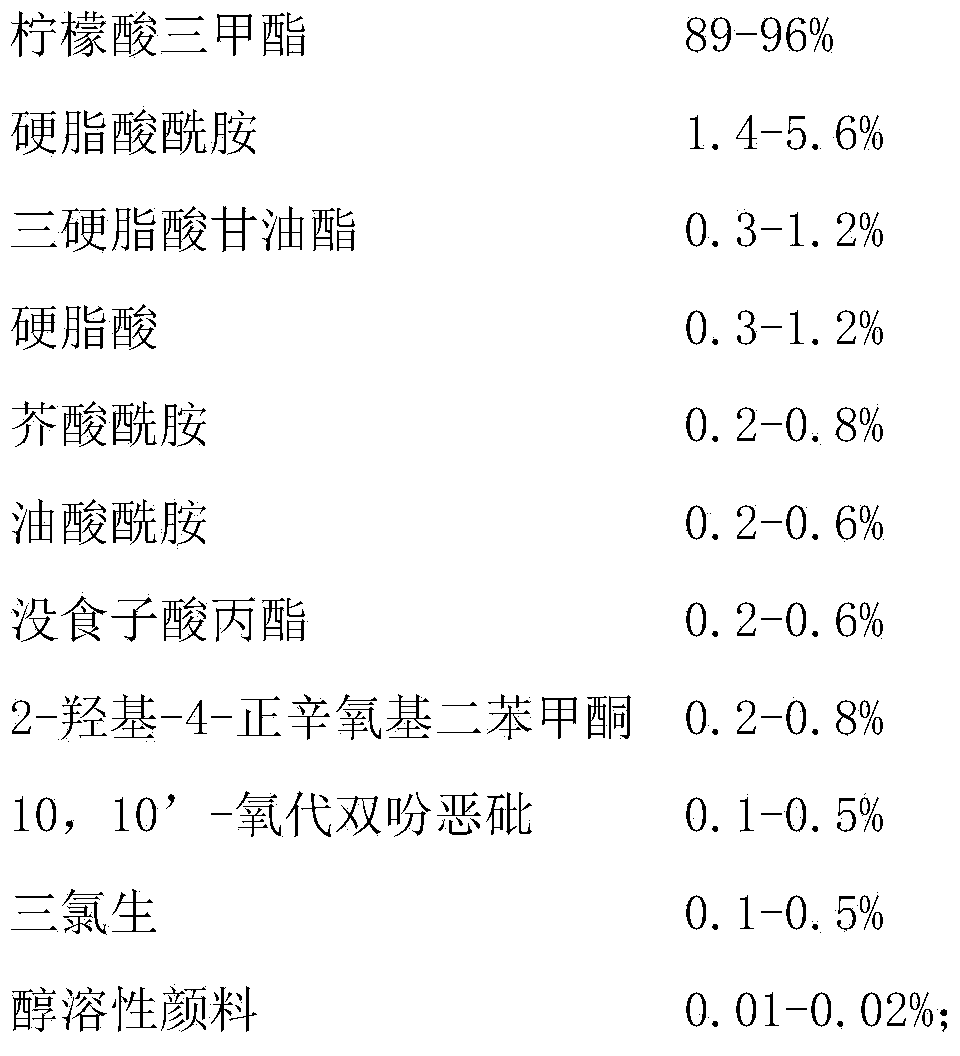

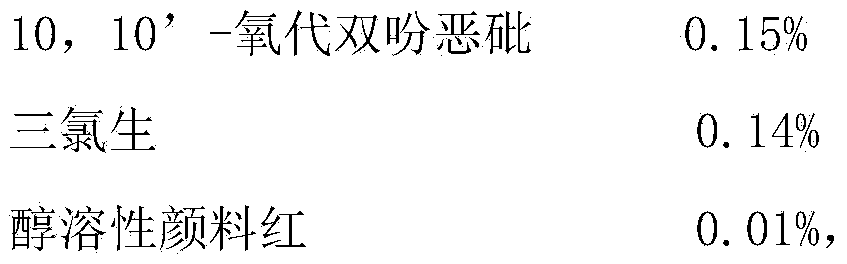

[0025] 94.6 grams of trimethyl citrate, 2.8 grams of stearic acid amide, 0.6 grams of glyceryl tristearate, 0.6 grams of stearic acid, 0.4 grams of erucamide, 0.3 grams of oleic acid amide, 0.2 grams of propyl gallate, 2 0.2 g of -hydroxy-4-n-octyloxybenzophenone, 0.15 g of 10,10'-oxobisphenoxarsenic, 0.14 g of triclosan, and 0.01 g of alcohol-soluble pigment red. Melt the above materials at 90°C and mix them evenly to obtain wax materials.

[0026] The red hair coloring agent uses 5 grams of lithium chloride, which is fully dissolved in 100 grams of pure water, soaks the wick for 4 hours, takes it out and dries it, and measures the size according to the needs and winds the tube for later use. Put the wrapped wick directly on the candle machine, 200 pieces can be worn at one time, pour the above melted wax material directly on the machine, pass cooling water on it, after solidification, it can be molded and released.

[0027] With this production me...

Embodiment 2

[0029] yellow flame candle

[0030] 88.98 grams of trimethyl citrate, 5.6 grams of stearic acid amide, 1.2 grams of glyceryl tristearate, 1.0 grams of stearic acid, 0.8 grams of erucamide, 0.5 grams of oleic acid amide, 0.4 grams of propyl gallate, 2 0.7 g of -hydroxy-4-n-octyloxybenzophenone, 0.4 g of 10,10'-oxobisphenoxarsenic, 0.4 g of triclosan, and 0.02 g of alcohol-soluble pigment yellow. Melt the above materials at 93°C and mix them evenly to obtain wax materials.

[0031] Yellow wicks require no special treatment because the wick itself contains sodium and gives off a yellow flame. Measure the size of the wick according to the needs and wind the tube for later use. Put the wrapped wick directly on the candle machine, 200 pieces can be worn at one time, pour the above melted wax material directly on the machine, pass cooling water on it, after solidification, it can be molded and released.

[0032] With this production method, one person can produce 200 candles by hi...

Embodiment 3

[0034] purple flame candle

[0035] 89.99 grams of trimethyl citrate, 4.9 grams of stearic acid amide, 1.0 grams of glyceryl tristearate, 1.0 grams of stearic acid, 0.7 grams of erucamide, 0.5 grams of oleic acid amide, 0.5 grams of propyl gallate, 2 0.8 g of -hydroxy-4-n-octyloxybenzophenone, 0.3 g of 10,10'-oxobisphenoxarsenic, 0.3 g of triclosan, and 0.01 g of alcohol-soluble pigment violet. Melt the above materials at 95°C and mix them evenly to obtain wax materials.

[0036]The purple chromogenic agent uses 5 grams of potassium chloride and 1 gram of lithium nitrate, which are fully dissolved in 100 grams of pure water, soaked for 24 hours, taken out, dried and coiled for later use. Put the wrapped wick directly on the candle machine, 200 pieces can be worn at one time, pour the above melted wax material directly on the machine, pass cooling water on it, after solidification, it can be molded and released.

[0037] With this production method, one person can produce 200...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com