Automatic grinding device and grinding method of ceramic inserting core inner hole

A technology of ceramic ferrule and grinding device, which is applied in the field of optical communication, can solve the problems of difficult control of aperture size, quality control due to many human factors, and non-circular hole shape, so as to achieve reliable quality of processed products and eliminate instability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

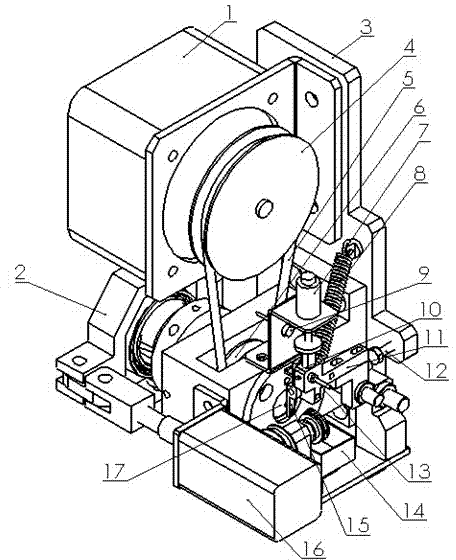

[0027] An automatic grinding device for the inner hole of a ceramic ferrule, including a PLC controller and a transmission device connected to the PLC controller respectively, a head part, a left steel wire tensioning device, a right steel wire tensioning device, etc. The touch screen is connected, and control buttons are arranged on the touch screen.

[0028] The transmission device includes a motor, a ball screw and a slide rail. The motor is placed at the rear of the equipment, and the ball screw and slide rail are located in the same plane at the front. The motor drives the ball screw to rotate through the synchronous belt, thereby driving the front part to move back and forth parallel to the left and right on the slide rail.

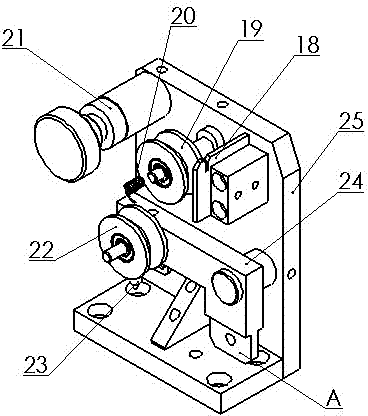

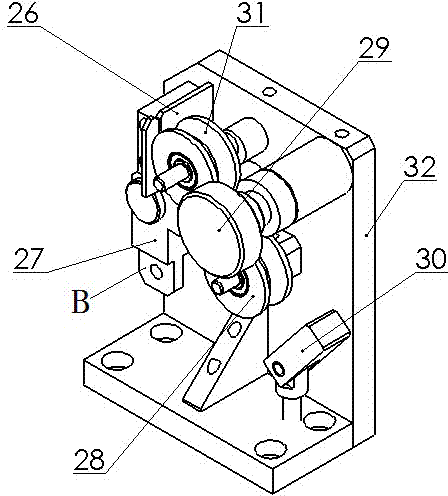

[0029] The structure of the head part is as figure 1 As shown, it includes: spindle motor 1, lever 2, bottom plate 3, large pulley 4, round plastic belt 5, small pulley 6, small cylinder 7, spring 8, first proximity switch 9, wire spring 10, rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com