Concrete Pavement Reinforced Condensation Joint Structure and Its Construction Method

A concrete pavement and construction method technology, applied to roads, roads, pavement details, etc., can solve the problem that the cutting seam cannot exert its effect to the greatest extent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

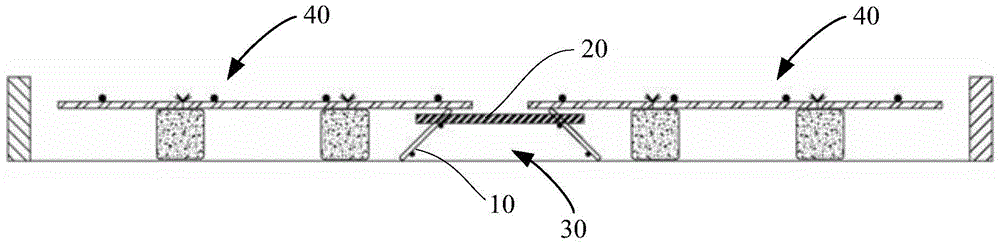

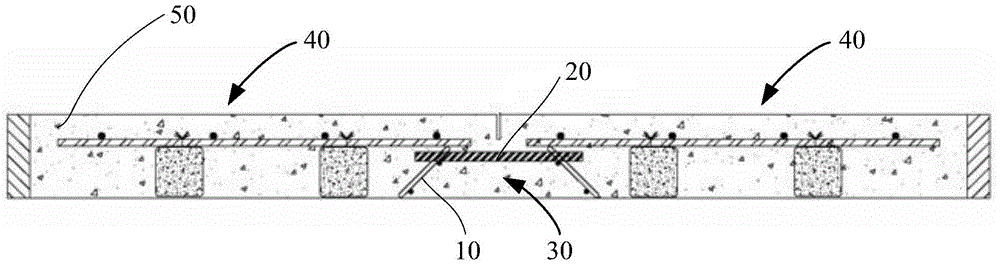

[0025] In order to facilitate the understanding of the structure of the present invention, the following description will be made in conjunction with the accompanying drawings and embodiments.

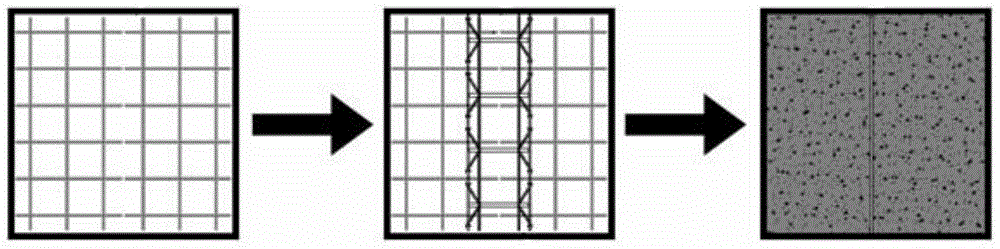

[0026] figure 1 It is a flow chart of the construction method of the reinforced concrete pavement shrinkage joint structure of the present invention.

[0027] see figure 1 , a construction method of reinforced concrete pavement shrinkage joint structure, comprising the following steps:

[0028] S1 Set out the position of the shrinkage joint area in advance on the construction site, bind the concrete pavement steel bars, the bound steel bars are bounded by the shrinkage joints and disconnected at the shrinkage joints, and the distance between the steel bars on both sides is 30mm after disconnection.

[0029] S2 Install dowel brackets on both sides of the steel bar break, provide a plurality of inverted "V"-shaped bars, the inverted "V"-shaped bars include two free ends and a connectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com