Method of accurate location of diamond turning tool in micro-turning process

A precise positioning, diamond technology, applied in metal processing, metal processing equipment, metal processing mechanical parts, etc., can solve the problems of inability to online detection, rely on labor, poor applicability, etc., to save configuration time, simple equipment, fast positioning speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

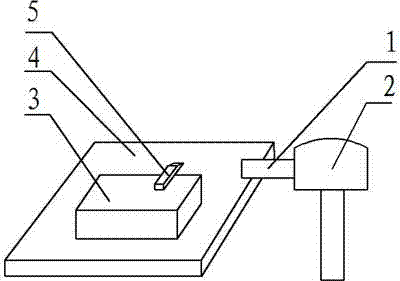

[0020] Such as figure 1 As shown, the present invention is a method for precise positioning of a diamond turning tool in a micro turning process.

[0021] 1. The positioning accuracy detection test is carried out on a self-made micro-turning platform. The precision positioning platform adopts a granite workbench and aerostatic guide rails. The positioning accuracy of the motion platform is 50nm; the resolution of the CCD is 1392×1040, and a controller based on DSP is used To realize the movement of the platform, the system can realize the closed-loop feedback control of the servo motor.

[0022] 2. Precisely center the diamond turning tool at the initial position, extract the CCD image of the tool, and set it as the original starting point of the coordinate system.

[0023] 3. The linear motor driver controls the longitudinal movement of the turning tool by 1mm, extracts the image of the tool at this position, and calculates the coordinate value of this position in the image ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com