Preparation method of <131>I<-> high-efficiency adsorbent in nuclear wastewater

A technology for nuclear wastewater and adsorbents, applied in chemical instruments and methods, nuclear engineering, other chemical processes, etc., can solve the problems of complex and expensive means, and achieve the effects of wide sources, low cost and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] 6g of 325 mesh anatase titanium dioxide particles were mixed with 80mL of 10M NaOH aqueous solution, and the mixed suspension was ultrasonically dispersed at 30W for 30min to make it uniformly dispersed.

[0037] Pour the ultrasonic dispersion liquid into the polytetrafluoroethylene lining of the hydrothermal reaction kettle, tighten the hydrothermal reaction kettle and put it into the oven. The temperature of the oven is adjusted to 180°C, and the reaction time is 48h.

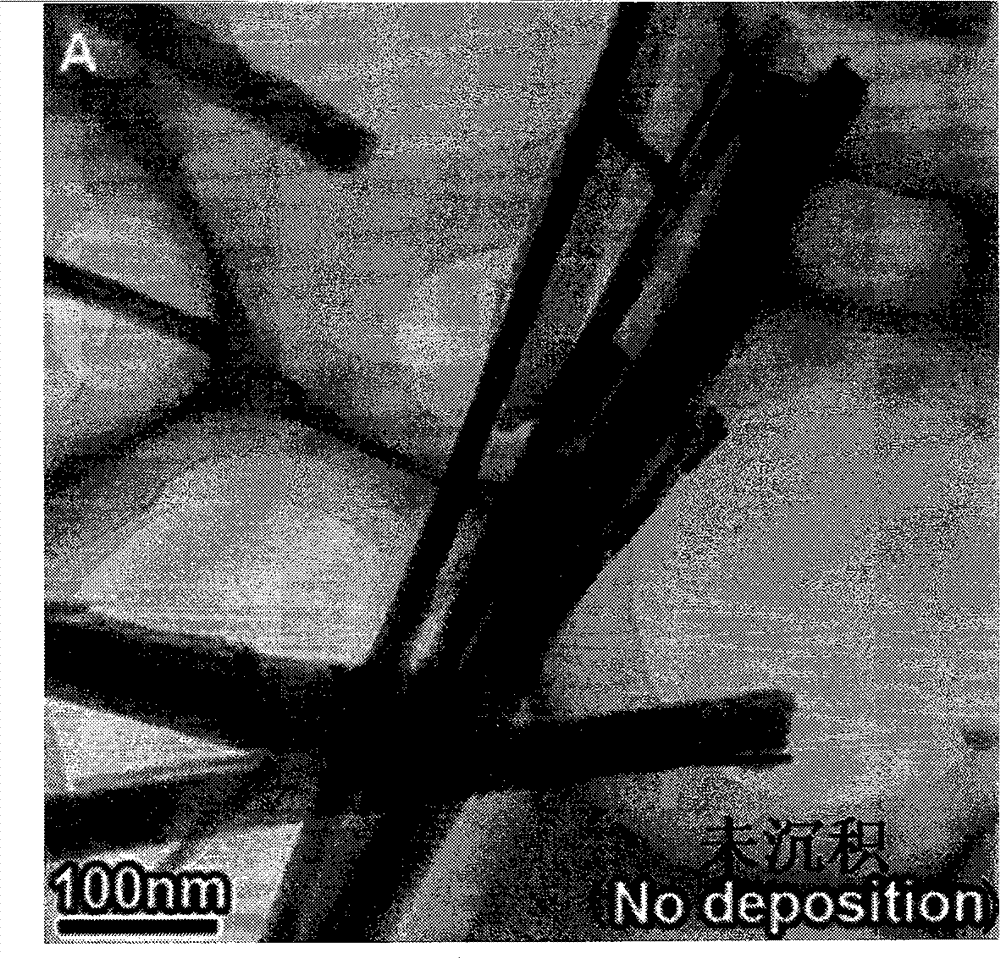

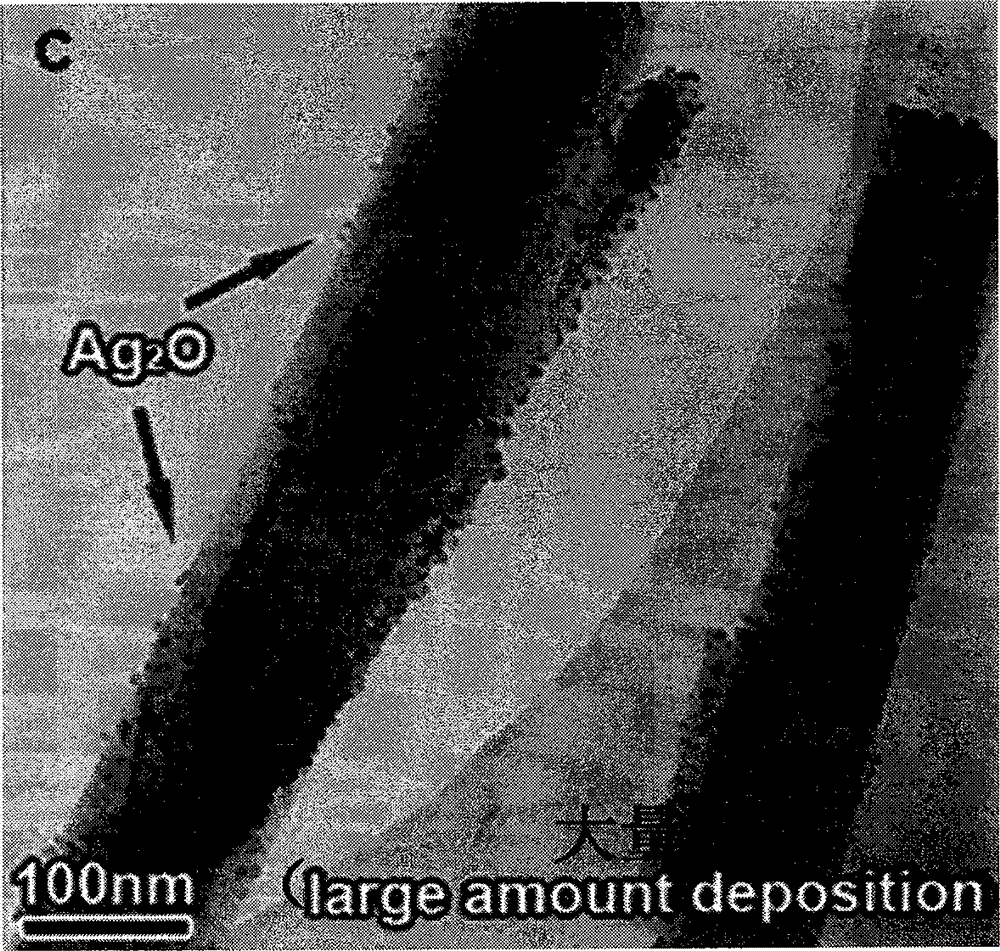

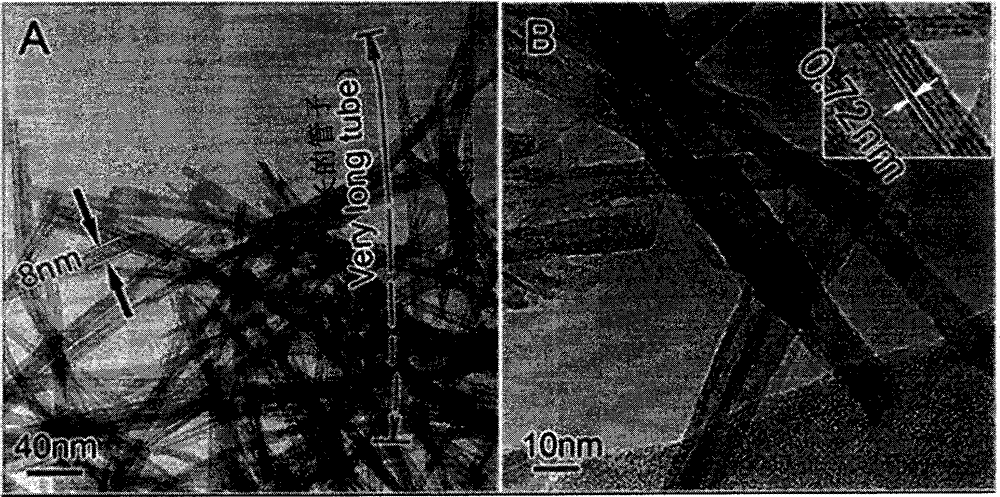

[0038] The precipitate after the hydrothermal reaction was collected, washed repeatedly with distilled water, and dried in vacuum at 80°C for 12 hours to obtain white Na 2 Ti 3 o 7 sodium titanate nanofibers.

[0039] Mix 2g of sodium titanate nanofibers with 2L of pure water evenly, and titrate with 1M NaOH solution, so that the pH of the dispersion is 11.

[0040] The alkalized dispersion was centrifuged at a speed of 10000 rpm for 10 minutes. Pour off the supernatant and collect the precipitate....

Embodiment 2

[0045] 12g of 325 mesh anatase titanium dioxide particles were mixed with 160mL of 10M NaOH aqueous solution, and the mixed suspension was ultrasonically dispersed at 30W for 30min to make it uniformly dispersed.

[0046] Pour the ultrasonic dispersion liquid into the polytetrafluoroethylene lining of the hydrothermal reaction kettle, tighten the hydrothermal reaction kettle and put it into the oven. The temperature of the oven is adjusted to 150°C, and the reaction time is 48h.

[0047]The precipitate after the hydrothermal reaction was collected, washed repeatedly with distilled water, and dried directly in an oven at 80°C for 12 hours to obtain white Na 2 Ti 3 o 7 sodium titanate nanotubes.

[0048] Mix 1 g of sodium titanate nanofibers with 1 L of pure water evenly, and titrate with 0.1 M NaOH solution, so that the pH of the dispersion is 10.5.

[0049] The alkalized dispersion was centrifuged at a speed of 12000 rpm and a centrifugation time of 6 min. Pour off the sup...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com