Preparation method of special silage for lactation sows

A technology for silage and suckling sows, applied in the field of roughage development, can solve the problems of single raw material, poor palatability, low lactation ability, etc., and achieve the effects of reducing the loss of nutrients, preventing mildew and rot, and promoting intestinal peristalsis.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

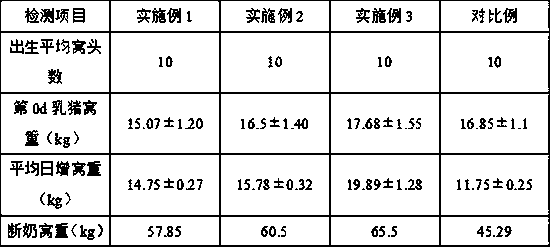

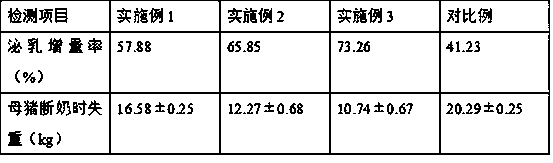

Examples

preparation example Construction

[0020] A method for preparing special silage for lactating sows, the preparation method comprising the steps of:

[0021] (1) According to parts by weight, take 30~40 parts of water, 10~15 parts of glucose, 7~8 parts of sucrose, 5~6 parts of soybean meal powder, 3~4 parts of beet pulp, 0.2~0.5 parts of potassium dihydrogen phosphate Mix evenly and sterilize at high temperature to obtain a nutrient solution. Put Bacillus licheniformis into the nutrient solution at a mass ratio of 1:5~6 for pure culture, and culture at a temperature of 45~50°C for 40~48h to obtain a nutrient solution. The mass ratio is 1:5~6, the lactic acid bacteria are inserted into the nutrient solution for pure culture, and the temperature is 35~37°C for 70~72h to obtain the culture solution a. According to the mass ratio of 1:1, the culture solution and the culture solution a are Mix to get a mixed solution, in parts by weight, take 30-40 parts of water, 10-15 parts of brown sugar, 5-6 parts of soybean meal...

Embodiment 1

[0026] Lipase powder was purchased from Henan Dongshun Chemical Products Co., Ltd.

[0027] The protective agent is calculated in parts by weight. Take 8 parts of n-butyl titanate, 22 parts of distilled water, 22 parts of hydrochloric acid, and 28 parts of ethanol into the container, and stir for 4 hours under normal pressure and temperature at 20°C to obtain a stirring liquid. Pulverize the montmorillonite to obtain a pulverized product, mix the pulverized product and the stirring liquid according to the mass ratio of 3:20, stir for 4 hours at normal pressure and a temperature of 30°C, filter to obtain a filter residue, wash the filter residue with water, and then Dry at a temperature of 50°C to obtain the protective agent.

[0028] A method for preparing special silage for lactating sows, the preparation method comprising the steps of:

[0029] (1) In parts by weight, take 30 parts of water, 10 parts of glucose, 7 parts of sucrose, 5 parts of soybean meal powder, 3 parts of b...

Embodiment 2

[0034] Lipase powder was purchased from Henan Dongshun Chemical Products Co., Ltd.

[0035] The protective agent is calculated in parts by weight. Take 10 parts of n-butyl titanate, 20 parts of distilled water, 24 parts of hydrochloric acid, and 30 parts of ethanol into the container, and stir for 5 hours under normal pressure and temperature at 50°C to obtain a stirring liquid. Pulverize the montmorillonite to obtain a pulverized product, mix the pulverized product and the stirring liquid according to the mass ratio of 3:25, stir for 6 hours at normal pressure and a temperature of 40°C, filter to obtain a filter residue, wash the filter residue with water, and then Dry at a temperature of 55°C to obtain the protective agent.

[0036] A method for preparing special silage for lactating sows, the preparation method comprising the steps of:

[0037] (1) In parts by weight, take 35 parts of water, 12 parts of glucose, 7 parts of sucrose, 5 parts of soybean meal powder, 3 parts o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com