Handwork imitation dough kneading machine based on pneumatic artificial muscle

A pneumatic artificial muscle and artificial muscle technology, applied in the field of food processing machinery, can solve the problems of low degree of automation, unprotected personal safety, single kneading force, etc., so as to improve production efficiency and safety, and achieve novel and reliable kneading. Mode selection, high degree of automation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

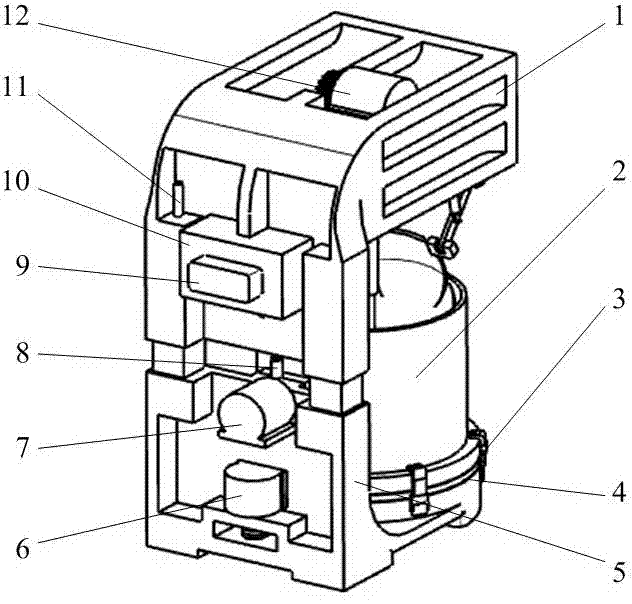

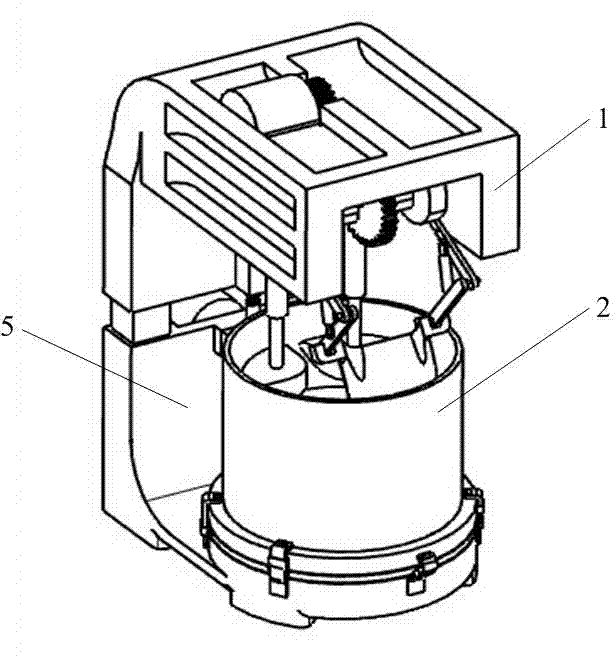

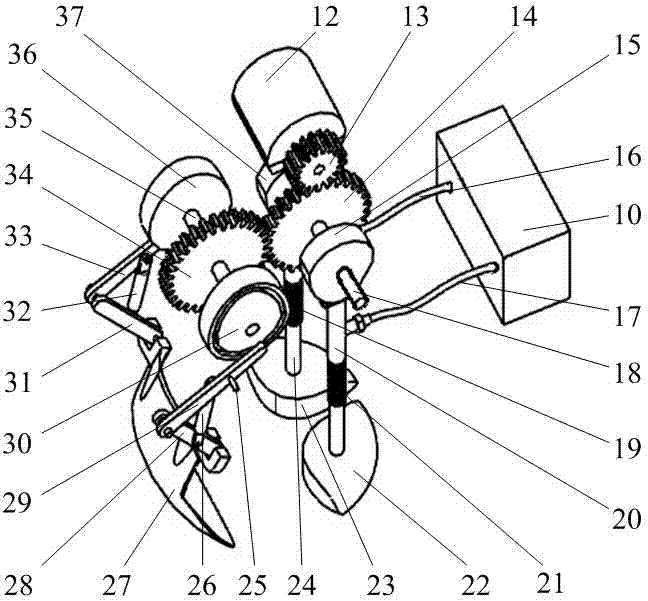

[0024] exist Figure 1 to Figure 9In the shown embodiment: the upper body 1 is directly above the lower body 5, the slide bar 11 is fixed on the lower body 5, the screw 8 is fixed on the inner vertical wall of the upper body 1, and the upper body 1 and the lower body 5 pass through the screw 8 Keep sliding connection with the slide bar 11, the worm gear 49 is sleeved on the lead screw 8 and threaded with it, the output end of the lifting motor 7 which is horizontally fixed on the outer wall of the lower body 5 is connected with the worm gear 49 through the worm 52, and the upper body 1 The upper part is welded with vertical fixed sleeve I 56 and fixed sleeve II 57, and the lower body 5 is provided with a turntable installation hole 50 and a turntable seat 51; the single-chip microcomputer controller 9 and the artificial muscle air distribution machine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com