Chemiluminiscence detection kit for 5 items of hepatitis B and preparation method thereof

A chemiluminescence detection and kit technology, applied in chemiluminescence/bioluminescence, analysis by making materials react chemically, measurement devices, etc., can solve problems such as unfavorable large-scale use, high cost, and economic burden, and achieve High degree of automation, saving manpower costs, and the effect of long-term testing platform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

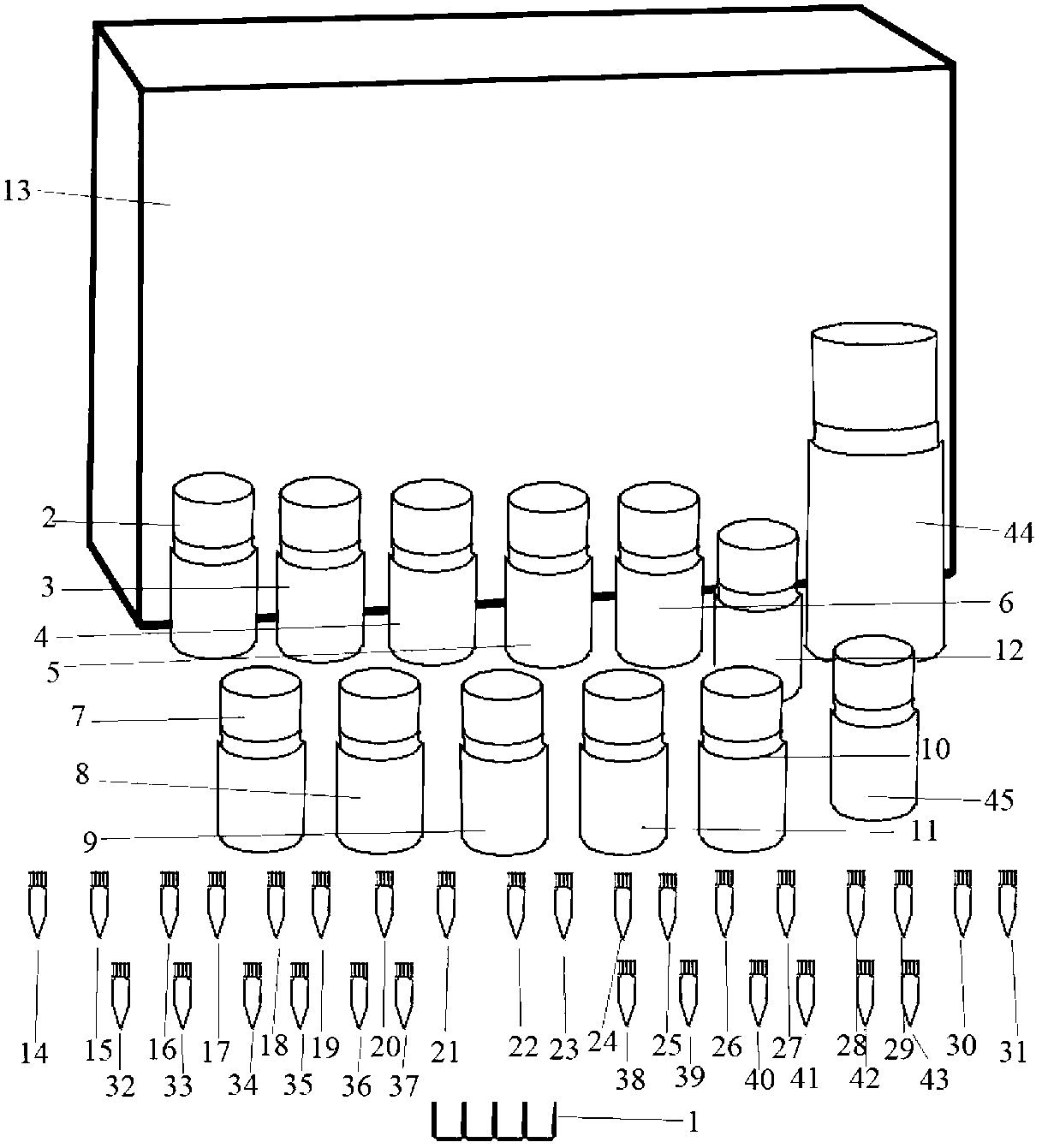

[0055] The preparation method of the five chemiluminescence quantitative detection kits for hepatitis B comprises the following steps:

[0056] 1. Preparation of Streptavidin Pre-coated Reaction Plate Preparation of Streptavidin Pre-coated Reaction Plate

[0057] Streptavidin was diluted with coating buffer. Take the reaction plate, and add the diluted streptavidin to the corresponding reaction plate, 150 μL per reaction plate. Place it at a constant temperature of 37°C for 2 hours for pre-coating. Shake off the coating solution, pat dry on clean absorbent paper, add 150 μL of sealing buffer to each reaction plate, and place at a constant temperature of 37°C for 2 hours. Remove the sealing solution, dry in a drying room at 37°C for 2 hours, and seal with a desiccant. The coating buffer is a Na2CO3-NaHCO3 buffer solution with a pH of 9.6 and 50 mmol / L, and the streptavidin dilution concentration is 8 μg / mL. The sealing buffer is 0.01mol / L TBS-T+(1%BSA, 0.2% gelatin). The r...

Embodiment 1

[0097] 1. Preparation of streptavidin pre-coated reaction plate

[0098] Streptavidin was diluted with coating buffer. Take the reaction plate, and add the diluted streptavidin to the corresponding reaction plate, 150 μL per reaction plate. Place it at a constant temperature of 37°C for 2 hours for pre-coating. Shake off the coating solution, pat dry on clean absorbent paper, add 150 μL of sealing buffer to each reaction plate, and place at a constant temperature of 37°C for 2 hours. Remove the sealing solution, dry in a drying room at 37°C for 2 hours, and seal with a desiccant. Described coating buffer is the Na of pH9.6, 50mmol / L 2 CO 3 -NaHCO 3 Buffer solution, the dilution concentration of streptavidin is 8 μg / mL. The sealing buffer is 0.01mol / L TBS-T+(1%BSA, 0.2% gelatin). The relative humidity of the drying room is less than 30%.

[0099] 2. Preparation of calibrator series

[0100] (1) Preparation of hepatitis B surface antigen calibrator

[0101] Dilute the ...

Embodiment 2

[0131] Similar to Example 1, the difference lies in the hepatitis B surface antibody in the specimen to be tested, and the sample, the hepatitis B surface antigen labeled with biotin and the hepatitis B surface antigen labeled with alkaline phosphatase are added to the solid phase of a microtube containing streptavidin. In the orifice plate, after reacting for 60 minutes, the hepatitis B surface antibody molecule specifically binds to the biotin-labeled hepatitis B surface antigen and the alkaline phosphatase-labeled hepatitis B surface antigen respectively, and the free components are washed away. Add luminescence substrate working solution, alkaline phosphatase substrate dephosphorylate, and emit 463nm visible light. The luminescence value RLU of each sample well was measured at the 15th minute. The RLU of the sample is positively correlated with the concentration of HBsAb in it. Sample results can be quantitatively calculated based on their RLU values.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com