Preparation method of monocrystalline AlN nanocones and nanosheets

A technology of nanocones and nanosheets, applied in the field of low-dimensional semiconductor nanostructure growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

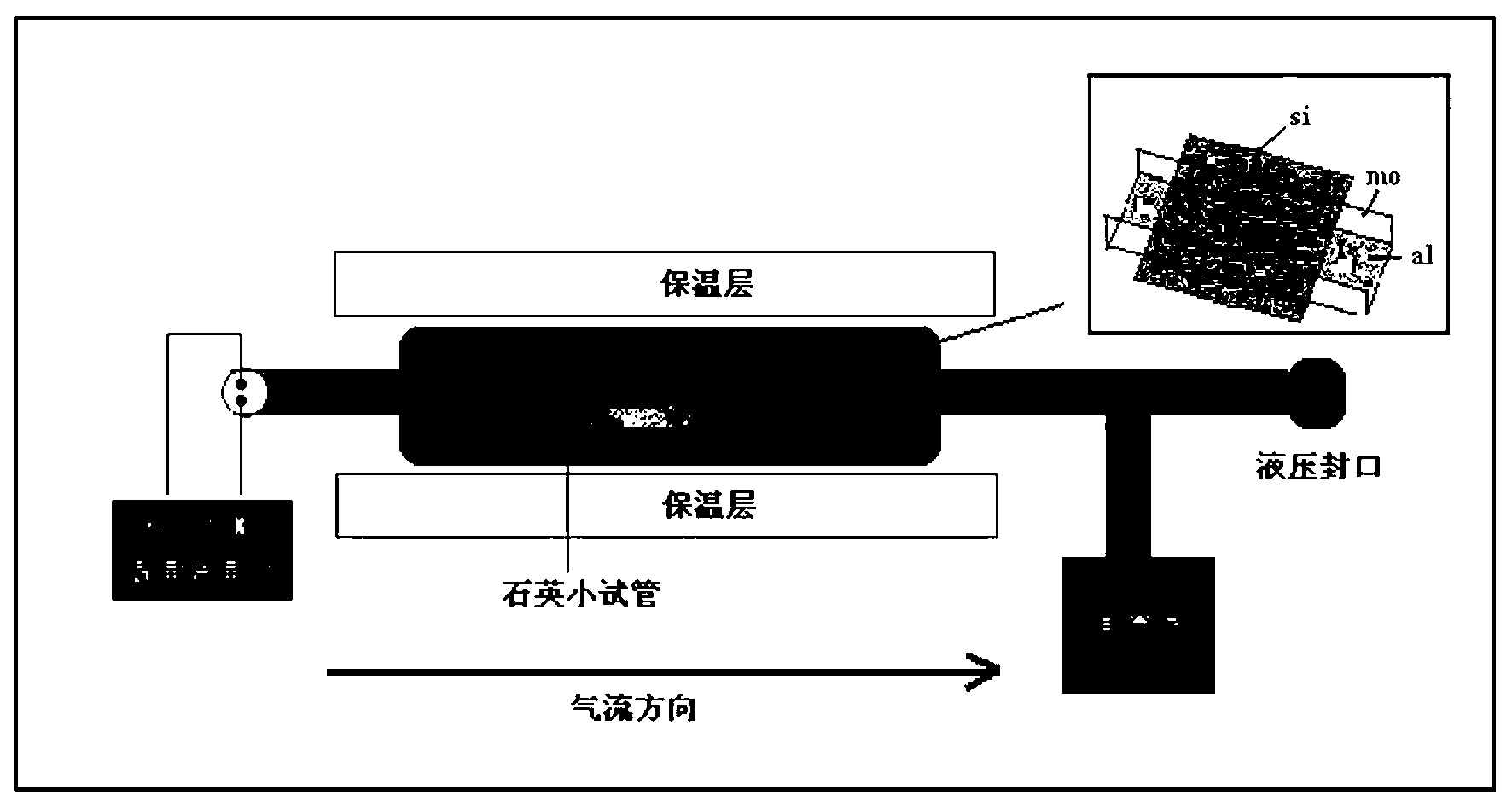

[0023] A preparation method of single crystal AlN nanocones and nanosheets, which is to spread 0.3 g of Al powder with a purity of 99.999% on a molybdenum boat, and buckle a silicon substrate deposited with a layer of aluminum powder directly above the molybdenum boat At 5-6 mm, put the molybdenum boat into a small quartz test tube with a diameter of 20 mm, and then place the small quartz tube in the reaction zone of a horizontal quartz tube furnace with a diameter of 80 mm. After sealing the vacuum system, start vacuuming. When the vacuum degree of the vacuum system is lower than 5 Pa, a flow rate of 500 sccm argon gas is introduced to flush the system. After 20 minutes, the flow of argon was turned off, and the system was heated. When the furnace temperature reached 900° C., 50 sccm of ammonia and argon were simultaneously fed in for 2 hours. Finally, stop the heating system, turn off the flow of ammonia gas when the temperature drops to 680 °C, and at the same time cool nat...

Embodiment 2

[0025] A preparation method of single crystal AlN nano-cones and nano-sheets is to put 0.3 g of Al powder with a purity of 99.999% into a molybdenum boat, and place the silicon wafer deposited with aluminum powder as a growth substrate on the positive side of the molybdenum boat. 5~6 mm above, put the molybdenum boat into a small quartz test tube with a diameter of 20 mm, and then place the small quartz tube in the reaction zone of a horizontal quartz tube furnace with a diameter of 80 mm. After sealing the vacuum system, start vacuuming. When the vacuum degree of the vacuum system is lower than 5 Pa, a flow rate of 500 sccm argon gas is introduced to flush the system. After 20 minutes, the flow of argon gas was turned off, and the system was heated. When the furnace temperature reached 850° C., 100 sccm of ammonia and argon gas were introduced and kept for 2 hours. Finally, stop the heating system, turn off the flow of ammonia gas when the temperature drops to 680 °C, and at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com