Light paraffin fuel gas rare earth catalytic synergist, as well as preparation method and application thereof

A light alkanes, rare earth catalysis technology, applied in the direction of fuel, gas fuel, petroleum industry, etc., can solve the problems of steel cylinder damage, strong irritation of additives, oxidative corrosion, solid particle crystallization, hidden safety hazards, etc., to achieve simple production , Conducive to long-distance transportation and storage, and the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

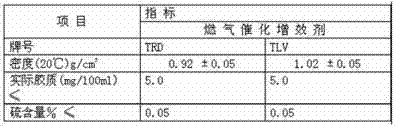

Image

Examples

Embodiment 1

[0040] First, add 15 parts of acetone and 0.45 parts of ferrocene into the preparation barrel and stir slowly with a stirring rod to completely dissolve the ferrocene; then add 42 parts of ethanol and 20 parts of petroleum ether and stir for 10-15 minutes to mix evenly. Finally, add 4.5 parts of cerium nitrate and stir to dissolve completely; then filter through 400-500 mesh filter to prepare additives, which can be used for preparing natural gas and metal cutting gas.

[0041] Inject 80 grams of the prepared catalyst into a natural gas steel cylinder, then flush 10 cubic meters of pipeline natural gas into the steel cylinder, and the two will naturally mix and gasify, that is, the natural gas metal cutting gas is prepared.

[0042] Natural gas (CH4) in light alkane fuel gas is currently the cheapest gas for cutting. Due to its slow combustion speed, low flame temperature, and correspondingly increased cutting preheating time, it is difficult to apply, and the calorific value ...

Embodiment 2

[0045] First, add 10 parts of acetone and 0.3 parts of ferrocene into the preparation barrel and stir slowly with a stirring rod to completely dissolve the ferrocene; then add 30 parts of ethanol and 15 parts of petroleum ether and stir for 10-15 minutes and mix well , and finally add 3.5 parts of cerium nitrate and stir to dissolve completely; then after filtering through 400-500 mesh filter, it is prepared as an additive, which can be used for the preparation of natural gas and metal cutting gas.

[0046] Inject 100 grams of the prepared catalytic synergist into the light alkane fuel gas steel cylinder, then flush 12 cubic meters of pipeline light alkane fuel gas into the steel cylinder, the two will naturally mix and gasify, that is, the light alkane fuel gas is prepared Alkane fuel gas metal cutting gas.

Embodiment 3

[0048] First, add 20 parts of acetone and 0.6 parts of ferrocene into the preparation barrel and stir slowly with a stirring rod to completely dissolve the ferrocene; then add 50 parts of ethanol and 25 parts of petroleum ether and stir for 10-15 minutes and mix well , and finally add 6 parts of cerium nitrate and stir to dissolve completely; then after filtering through 400-500 mesh filter, it is prepared as an additive, which can be used for the preparation of natural gas and metal cutting gas.

[0049] Inject 80 grams of the prepared catalyst synergist into the light alkane fuel gas steel cylinder, then flush 10 cubic meters of pipeline light alkane fuel gas into the steel cylinder, the two will naturally mix and gasify, that is, the light alkane fuel gas is prepared Alkane fuel gas metal cutting gas.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com