Synthetic fluid gas gasification furnace

A gas and liquid technology, applied in the field of synthetic liquid gasifier, can solve the problems of short process, low combustion utilization rate, large gas waste, etc., and achieve the effect of clean and hygienic combustion process, full combustion, and high thermal efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

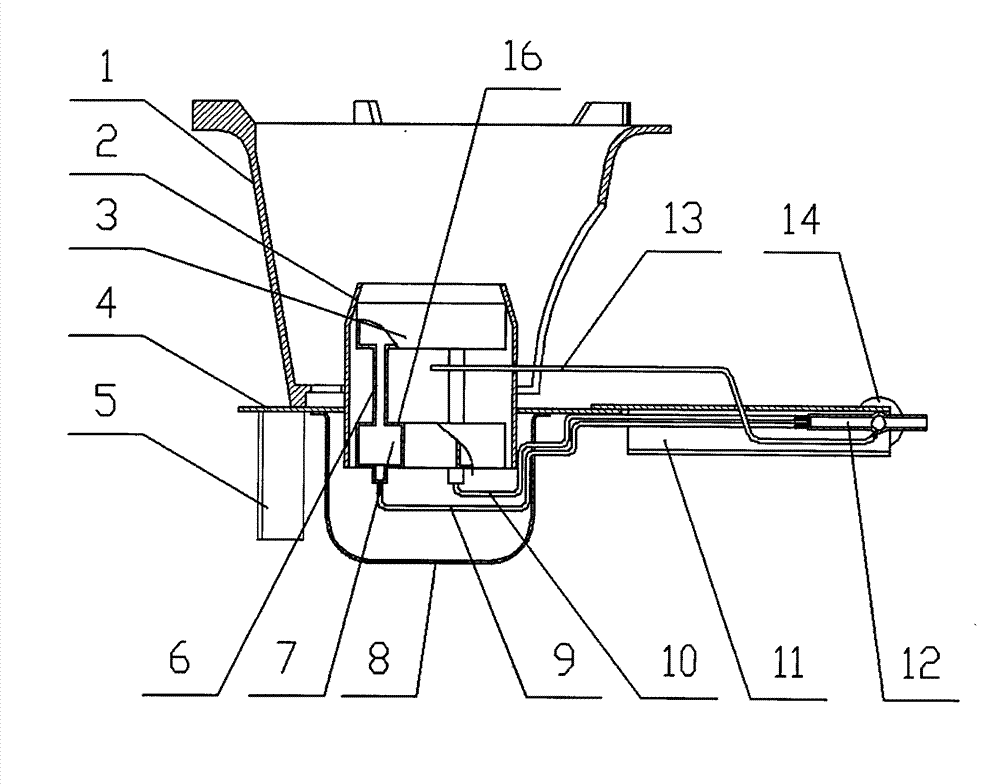

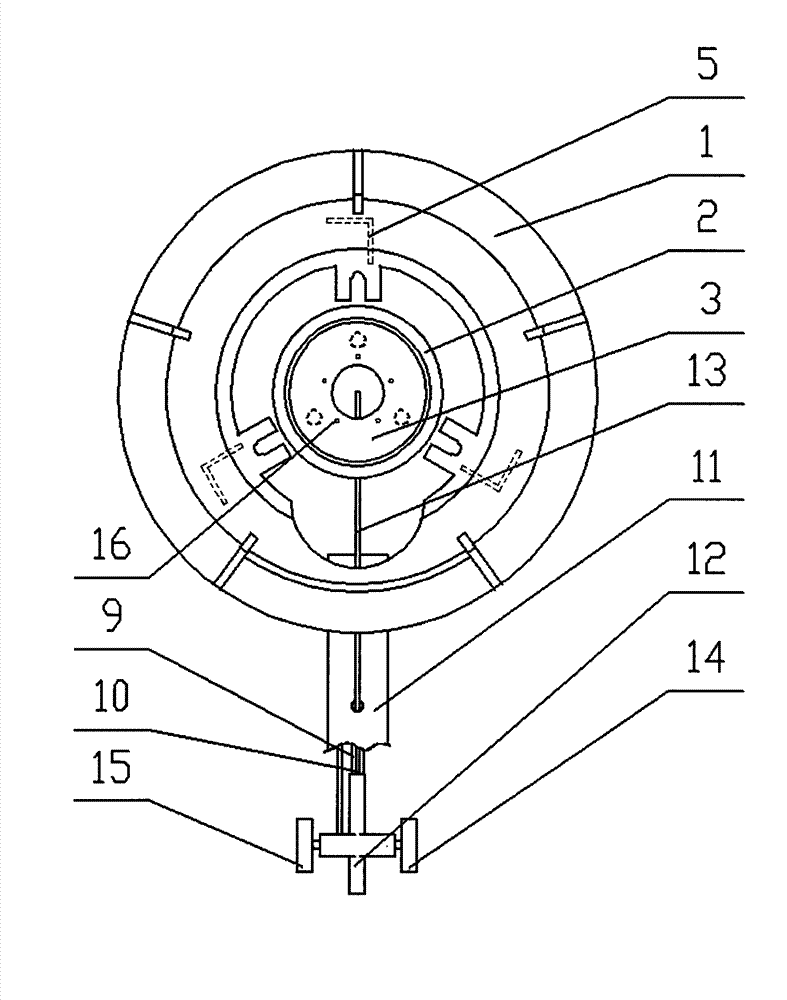

[0011] The structure of the synthetic liquid gas gasification furnace of the present invention will be further described below in conjunction with the accompanying drawings.

[0012] Referring to the accompanying drawings, the synthetic liquid gas gasification furnace of the present invention includes a fireproof ring 1, an ignition pan 8 at the bottom of the furnace, a support basin 4, a furnace foot 5 installed at the bottom of the support basin 4, and a combustion chamber cover installed in the middle of the support basin 4 2 and the combustion chamber in the combustion chamber cover 2, the handle 11, the liquid input pipe 12, the ignition gas delivery pipe 13 and the control valve 15, the first and second combustion gas delivery pipes 9, 10 and the control valve 14, etc.; The combustion chamber comprises a lower combustion chamber 7 provided with gas outlet holes 16, an upper combustion preheating chamber 3, and a combustor gas pipe 6 connected between the lower combustion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com