Fire coal additive and preparation method thereof

A technology of coal-burning additives and combustion-supporting agents, which is applied in the direction of fuel additives, fuels, and solid fuels. The effect of SO2 emission and the convenience of mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The weight composition of raw material used is as follows:

[0032] 2 parts of magnesium chloride;

[0033] 3 parts sodium sulfate;

[0034] Potassium nitrate 3 parts;

[0035] Potassium permanganate 1 part;

[0036] 8 parts of sodium chlorate;

[0037] 8 parts of ethanolamine;

[0038] 7 parts of isopropanolamine;

[0039] 3 parts calcium hydroxide;

[0040] 4 parts of cerium nitrate;

[0041] Under normal temperature and pressure, the above materials are crushed through a 60-mesh sieve, mixed and dissolved in water of 8 times the weight, and stirred evenly to form a solution to obtain the coal-burning additive product 1 of the present invention.

Embodiment 2

[0043] The weight composition of raw material used is as follows:

[0044] 5 parts of magnesium chloride;

[0045] Sodium sulfate 8 parts;

[0046] Potassium nitrate 6 parts;

[0047] Potassium permanganate 5 parts;

[0048] Sodium chlorate 2 parts;

[0049] 4 parts of ethanolamine;

[0050] 3 parts of isopropanolamine;

[0051] 3 parts calcium hydroxide;

[0052] 4 parts of cerium nitrate;

[0053] Under normal temperature and pressure, the above materials are crushed through a 60-mesh sieve, mixed and dissolved in water 10 times the weight, and stirred evenly to form a solution to obtain the coal-burning additive product 2 of the present invention.

Embodiment 3

[0055] The weight composition of raw material used is as follows:

[0056] 4 parts of magnesium chloride;

[0057] Sodium sulfate 5 parts;

[0058] Potassium nitrate 4 parts;

[0059] Potassium permanganate 3 parts;

[0060] Sodium chlorate 6 parts;

[0061] 5 parts of ethanolamine;

[0062] 4 parts of isopropanolamine;

[0063] 6 parts of calcium hydroxide;

[0064] 6 parts of cerium nitrate;

[0065] Under normal temperature and pressure, the above materials are crushed through a 60-mesh sieve, mixed and dissolved in water of 10 times the weight, and stirred evenly to form a solution to obtain the coal-fired additive product 3 of the present invention.

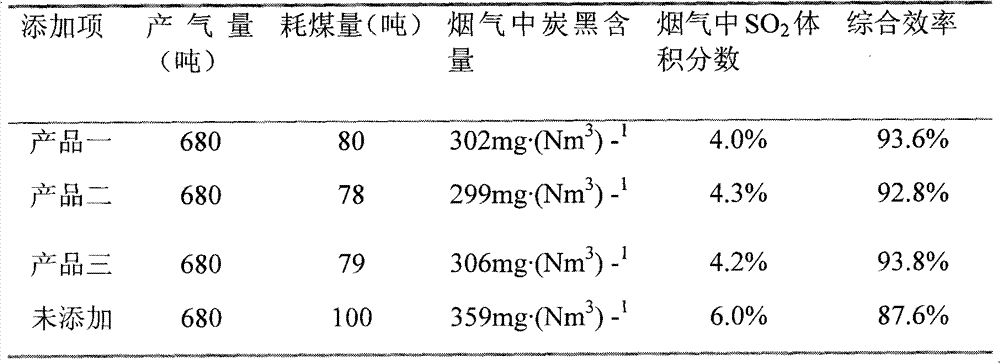

[0066] The additive products obtained in Examples 1-3 of the present invention (the addition amount is 0.5%) are added to the coal fired boiler and the coal fired without the additive of the present invention is used under the same conditions in the same boiler, and the results of various combustion performance indica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com