Sealing material for steel bar grouting connection components and its preparation method and application

A sealing material and grouting connection technology, which is applied in the direction of building components, building material processing, structural elements, etc., can solve the problems of poor adhesion, high price, economic loss, etc., achieve strong deformation resistance, improve construction efficiency, The effect of long operation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

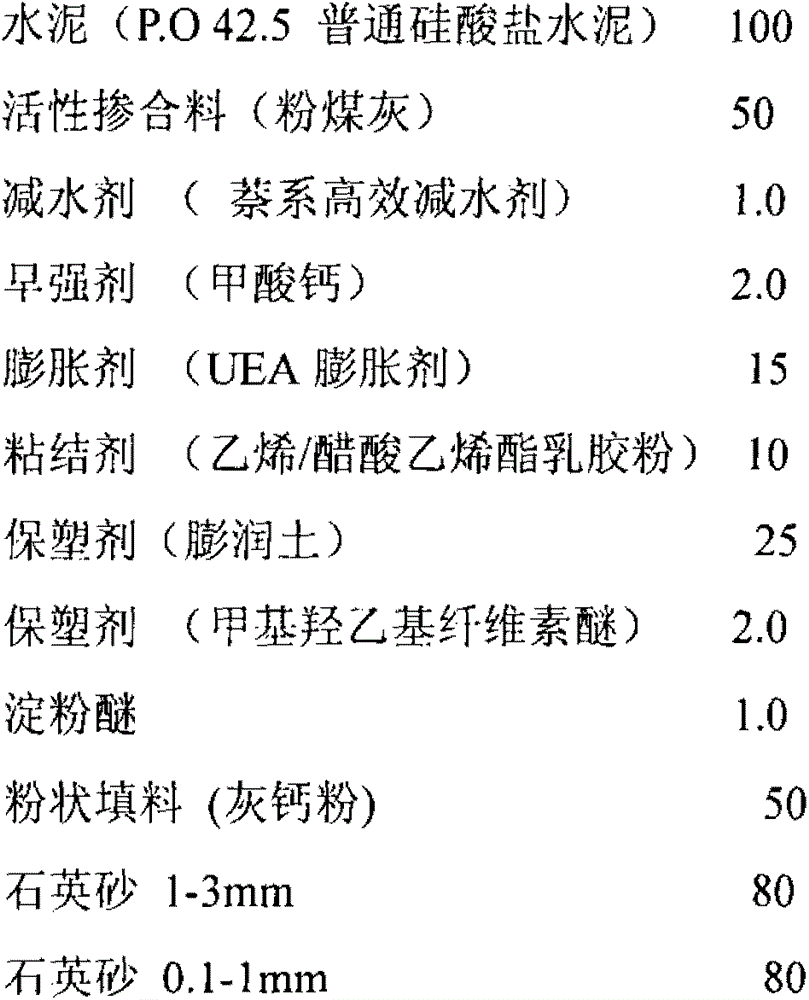

Embodiment 1

[0075]

[0076] Preparation method: Weigh various raw materials according to the formula, add quartz sand, powdery filler (ash calcium powder), cement (P.O 42.5 ordinary Portland cement), active admixture (fly ash), reducing Water agent (naphthalene-based high-efficiency water reducer), early strength agent (calcium formate), expansion agent (UEA expansion agent), binder (ethylene / vinyl acetate latex powder), plastic retainer (bentonite, methyl hydroxyethyl base cellulose ether), starch ether, fully stirred evenly, and packaged to form a product.

[0077] The construction method is as mentioned above, wherein the amount of water added is 15% of the weight of the sealing material.

[0078] The sealing material prepared from the above components according to the aforementioned process has the characteristics of long operating time, high strength, strong cohesive force and good plasticity, and is suitable for construction in summer.

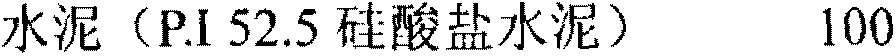

Embodiment 2

[0080]

[0081]

[0082] Preparation method: Weigh various raw materials according to the formula, and add quartz sand, powder filler (calcium carbonate powder), cement (Portland cement), active admixture (silica fume), water reducing agent (polycarboxylate) into the mixer in sequence Acid superplasticizer), early strength agent (anhydrous sodium sulfate), expansion agent (UEA expansion agent), binder (polyvinyl alcohol), plastic retainer (bentonite, methyl cellulose), modified starch ether, Stir fully and evenly, and pack to form the product.

[0083] The construction method is as mentioned above, wherein the amount of water added is 20% of the weight of the sealing material.

[0084] The sealing material prepared from the above components according to the aforementioned process has the characteristics of moderate setting time, high strength, strong cohesive force and good plasticity, and is suitable for construction in spring and autumn.

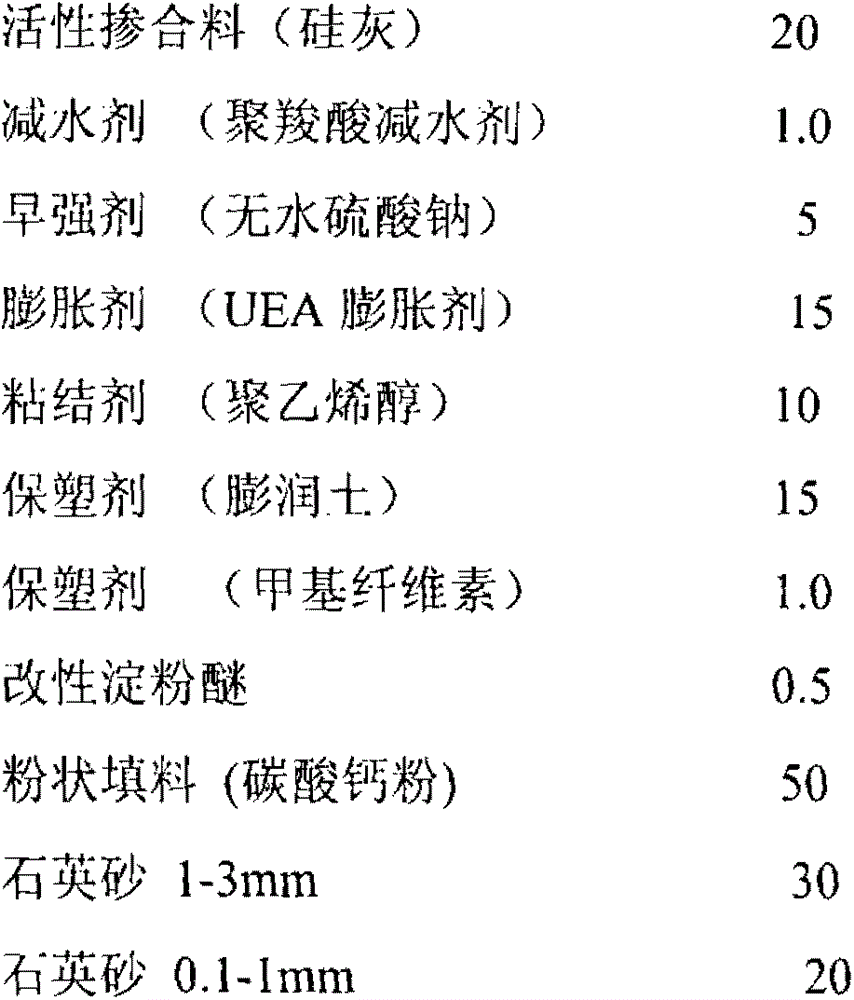

Embodiment 3

[0086]

[0087]

[0088] Preparation method: Weigh various raw materials according to the formula, and add quartz sand, powdery filler (talc powder), cement (aluminate cement), active admixture (silica fume, slag powder), and water reducer to the mixer in sequence (melamine superplasticizer), early strength agent (calcium formate), expansion agent (ZY expansion agent), binder (vinyl acetate homopolymer powder), plastic retainer (diatomaceous earth, carboxymethyl cellulose) , starch ether, fully stirred evenly, and packaged to form a product.

[0089] The construction method is as mentioned above, wherein the amount of water added is 16% of the weight of the sealing material.

[0090] The sealing material prepared from the above components according to the aforementioned process has the characteristics of short setting time, high early strength, strong cohesive force and good plasticity, and is suitable for winter construction and occasions where the construction period o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com