Fluorescent powder/silicon-based mesoporous material composite fluorescent glass and preparation method thereof

A silicon-based mesoporous material and luminescent glass technology, applied in glass manufacturing equipment, glass molding, manufacturing tools, etc., can solve the problems of high energy consumption, high melting temperature, and long melting time, and achieve good thermal conductivity and preparation Simple process and good anti-aging performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] According to YAG:Ce 3+ The molar percentage of MCM-41 powder is 3%: 97% and weigh YAG:Ce 3+ and MCM-41 powder, and then put the two into a ball mill tank for wet ball milling for 12 hours. Alcohol should be added during the ball milling process to ensure uniform mixing. After ball milling, put the powder into the drying box to dry. After drying, put the powder into graphite mold and put it into SPS equipment for sintering. SPS sintering is carried out under vacuum conditions, the pressure applied during the sintering process is 50MPa; the heating rate during sintering is 50°C / min; the sintering temperature is 1150°C; the holding time is 5min. After the sintering is completed, turn off the power of the instrument, and cool down to room temperature with the furnace. After the sample is taken out, the luminescent glass block is obtained through grinding, polishing and other processes.

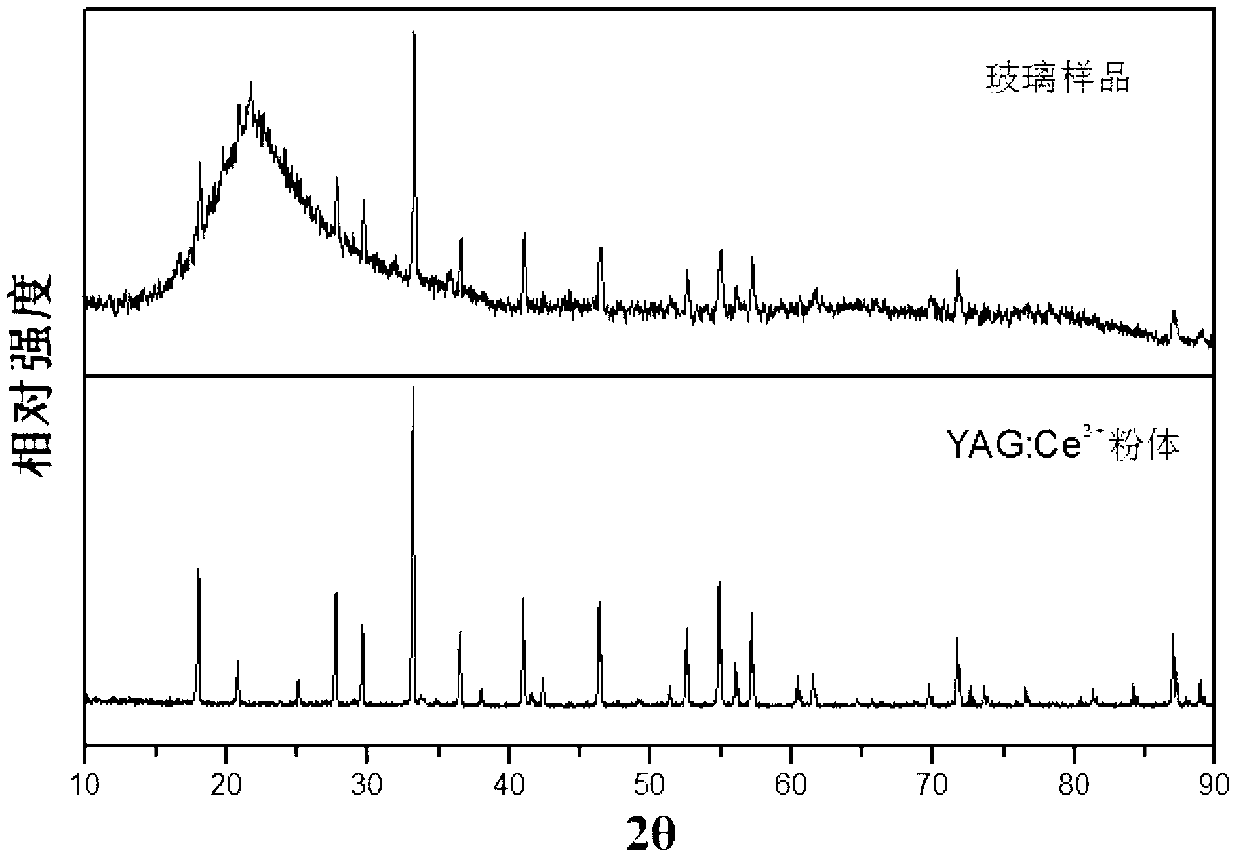

[0027] Carry out XRD test to the prepared luminous glass, the result obtained is as...

Embodiment 2

[0029] According to YAG:Ce 3+ The molar percentage of mesoporous SBA-15 powder is 0.4%: 99.6% and weigh YAG:Ce 3+ and SBA-15 powder, and then put the two into a ball mill tank for wet ball milling for 12 hours. Alcohol should be added during the ball milling process to ensure uniform mixing. After ball milling, put the powder into the drying box to dry. After drying, put the powder into graphite mold and put it into SPS equipment for sintering. SPS sintering is carried out under vacuum conditions, and the pressure applied during the sintering process is 50MPa. The heating rate during sintering is 80°C / min; the sintering temperature is 1080°C; the holding time is 2min. After the sintering is completed, turn off the power of the instrument, and cool down to room temperature with the furnace. After the sample is taken out, the luminescent glass block is obtained through grinding, polishing and other processes.

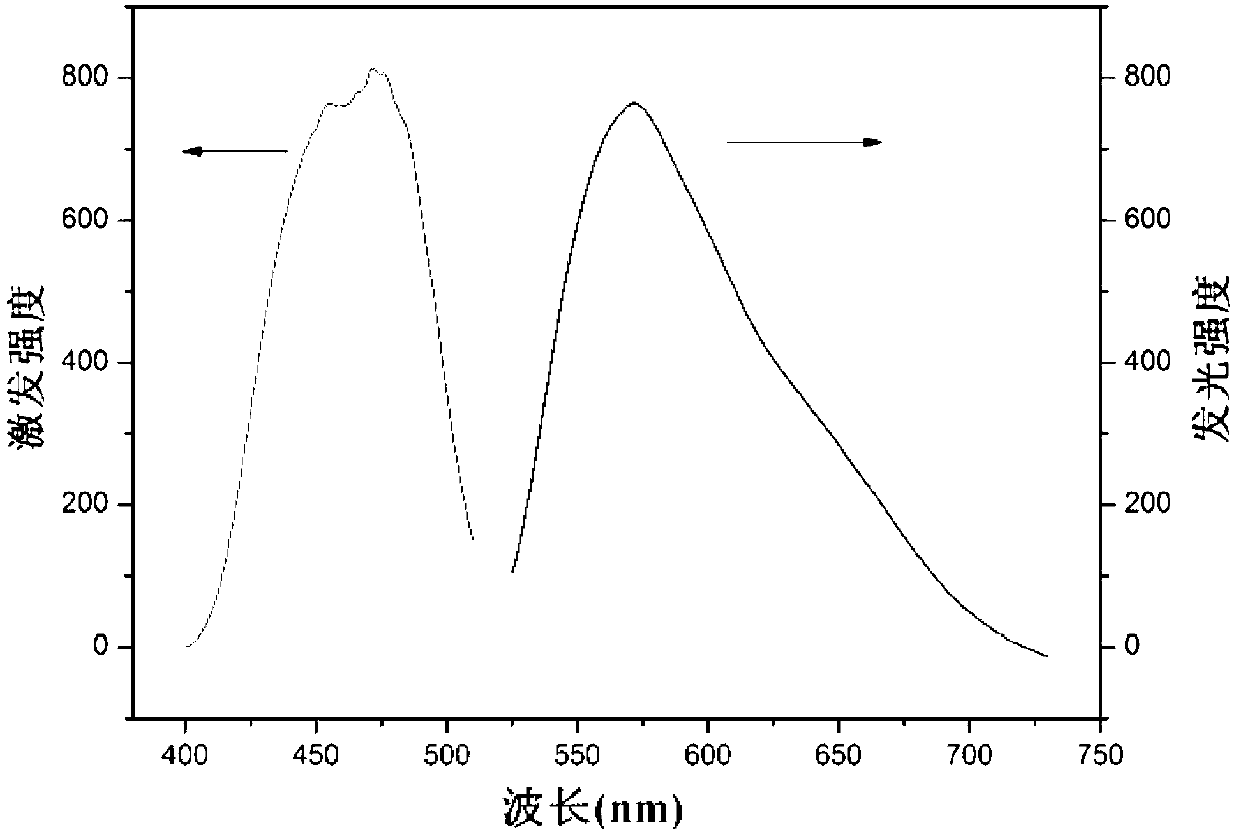

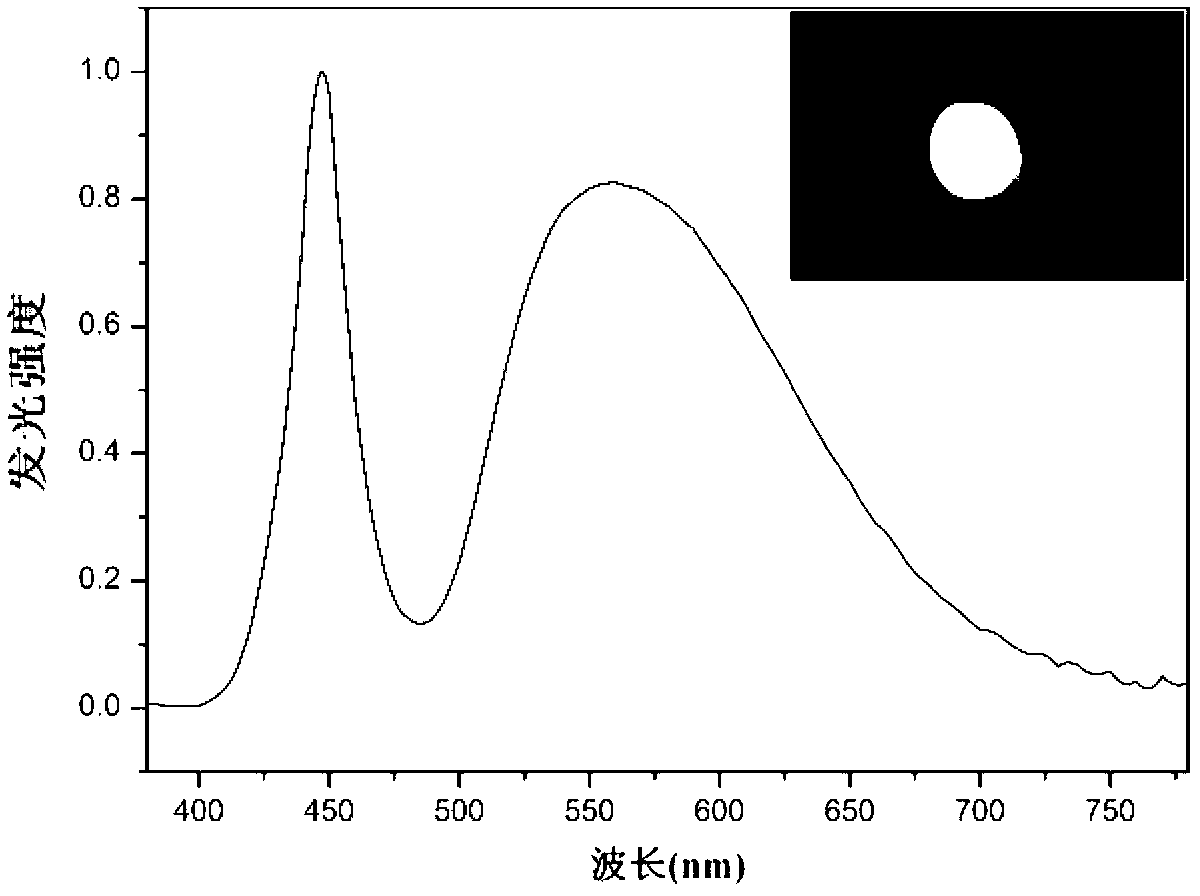

[0030] Excitation and emission spectrum tests were carried out ...

Embodiment 3

[0033] According to YAG:Ce 3+ And MCM-48 mole percentage is 0.5%: 99.5% ratio to weigh YAG: Ce 3+ and MCM-48 powder, and then put the two into a ball mill jar for wet ball milling for 8 hours. Alcohol should be added during the ball milling process to ensure uniform mixing. After ball milling, put the powder into the drying box to dry. After drying, put the powder into graphite mold and put it into SPS equipment for sintering. SPS sintering is carried out under vacuum conditions, the pressure applied during the sintering process is 75MPa; the heating rate during sintering is 90°C / min; the sintering temperature is 1050°C; the holding time is 3min. After the sintering is completed, turn off the power of the instrument, and cool down to room temperature with the furnace. After the sample is taken out, the luminescent glass block is obtained through grinding, polishing and other processes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| color rendering index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com