Method and device for continuous detection of the thickness and/or homogeneity of linear objects, particularly textile fibres, and their application

A technology for textile fibers and detection lines, which is used in continuous detection of the thickness and/or uniformity of linear objects, especially textile fibers, and equipment and its application fields, which can solve the problem of small distances (no more than a few mm, and the need to place the line Fixed position in the measuring field, etc., to achieve the effect of helping maintenance and cleaning, simplifying handling, and reducing dust generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

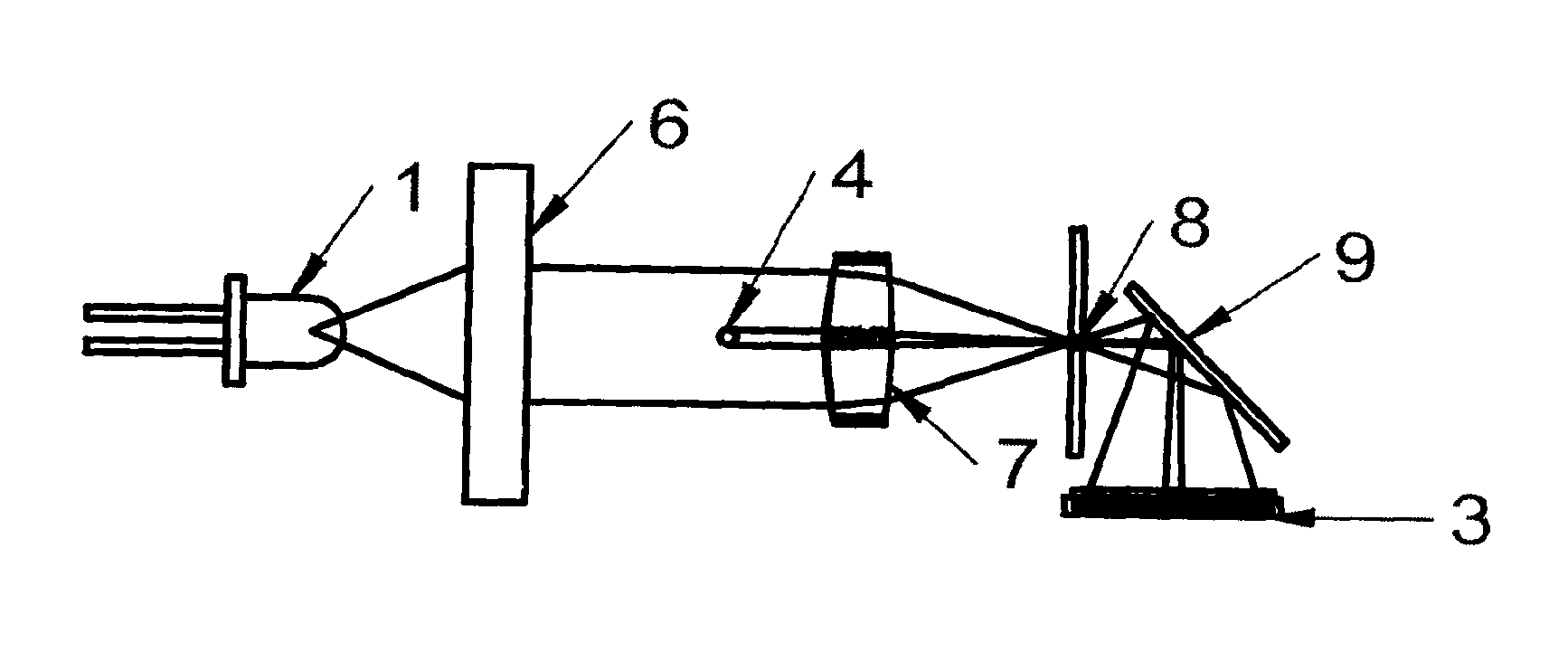

[0052] Figure 1 shows a diagram of the basic embodiment. Monochromatic point sources such as laser diodes 1 is placed on the collimating element 2 For example the focal point of a lens (a spherical lens or a doublet or a pair of cylindrical lenses). A collimated beam is produced at the output of the self-lens 12 . placed in the beam 12 fibers in 4 The image falls through the optical bandpass filter 11 on, and through an optical bandpass filter 11 Fall to CCD / CMOS sensor 3 superior. The image from the sensor is controlled by the programmable logic field 18 process and output 19 on record.

example 2

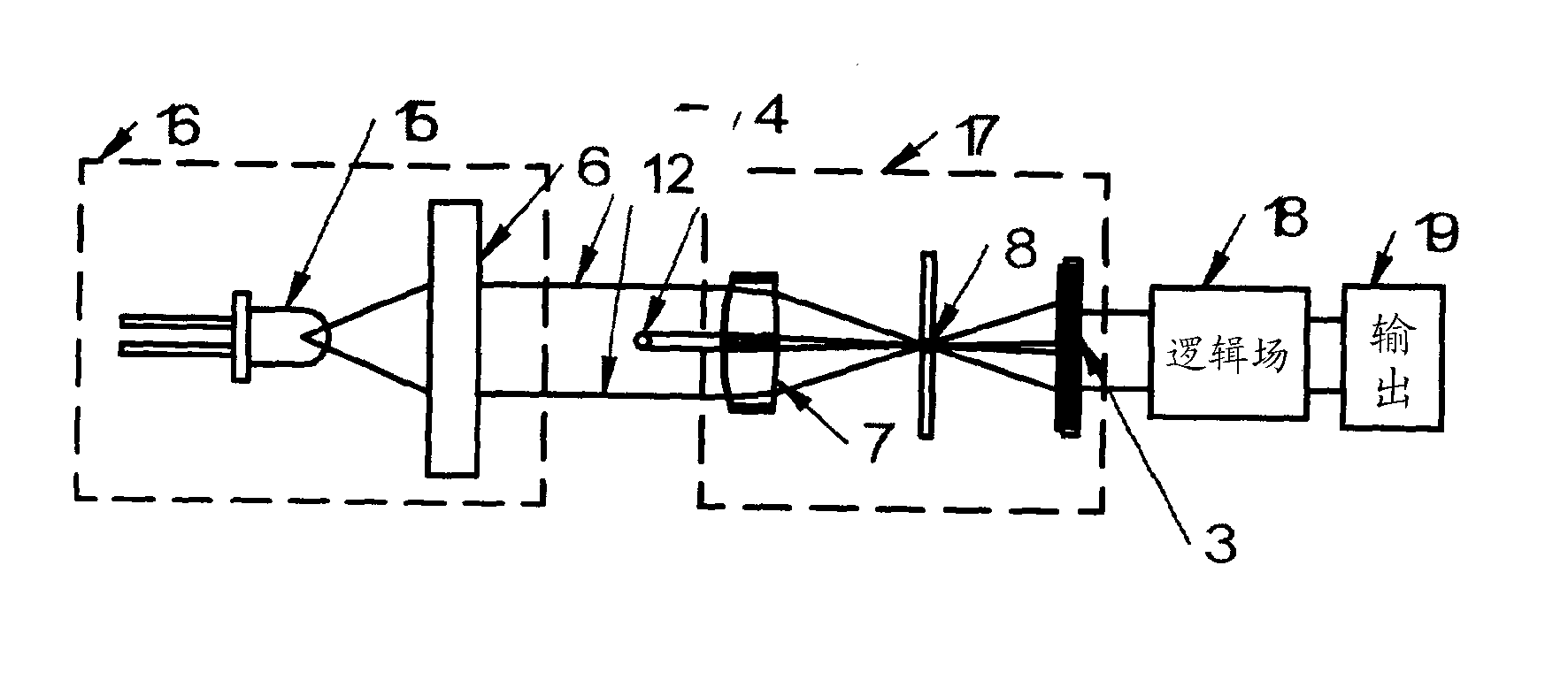

[0054] Figure 2 shows a modification of the former type of implementation, where a point source of light is used using a shutter 20 surface light source 15 (eg LED) replacement, which actually simulates a point light source as described in Example 1.

example 3

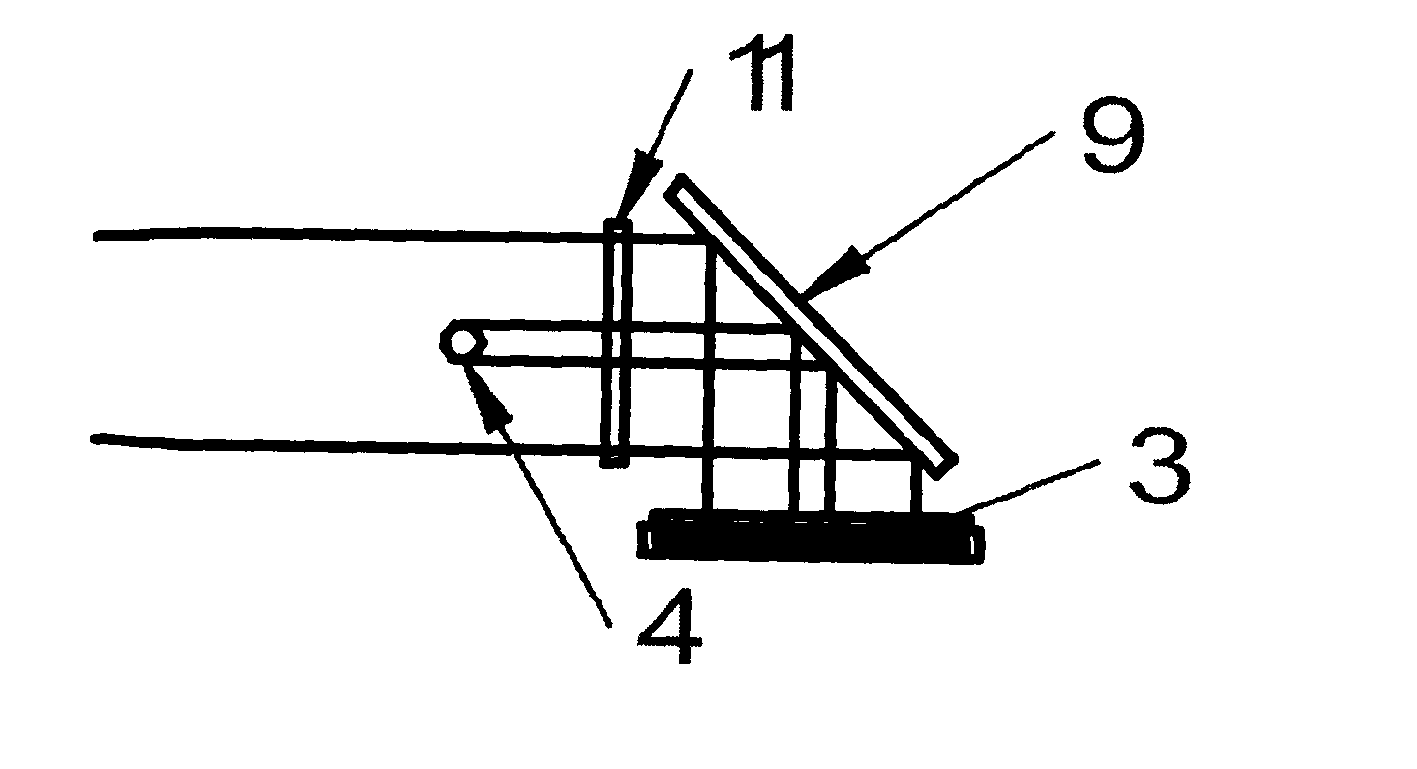

[0056] Figure 3 shows the mirror 9 is placed on the optical sensor 3 previous implementation. In this mirror with optical filter 11 and sensors 3 There is an angle of 45 degrees between them. This manner of embodiment may, for example, facilitate integration in compact devices.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com