Hard x-ray micro-focus multi-thickness ratio compound multilayer laue lens

A composite multi-layer film, thickness ratio technology, applied in layered products, application of diffraction/refraction/reflection for processing, etc., can solve problems such as large attenuation of incident light flux, limited light flux, and difficulty in making the lens diameter larger.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

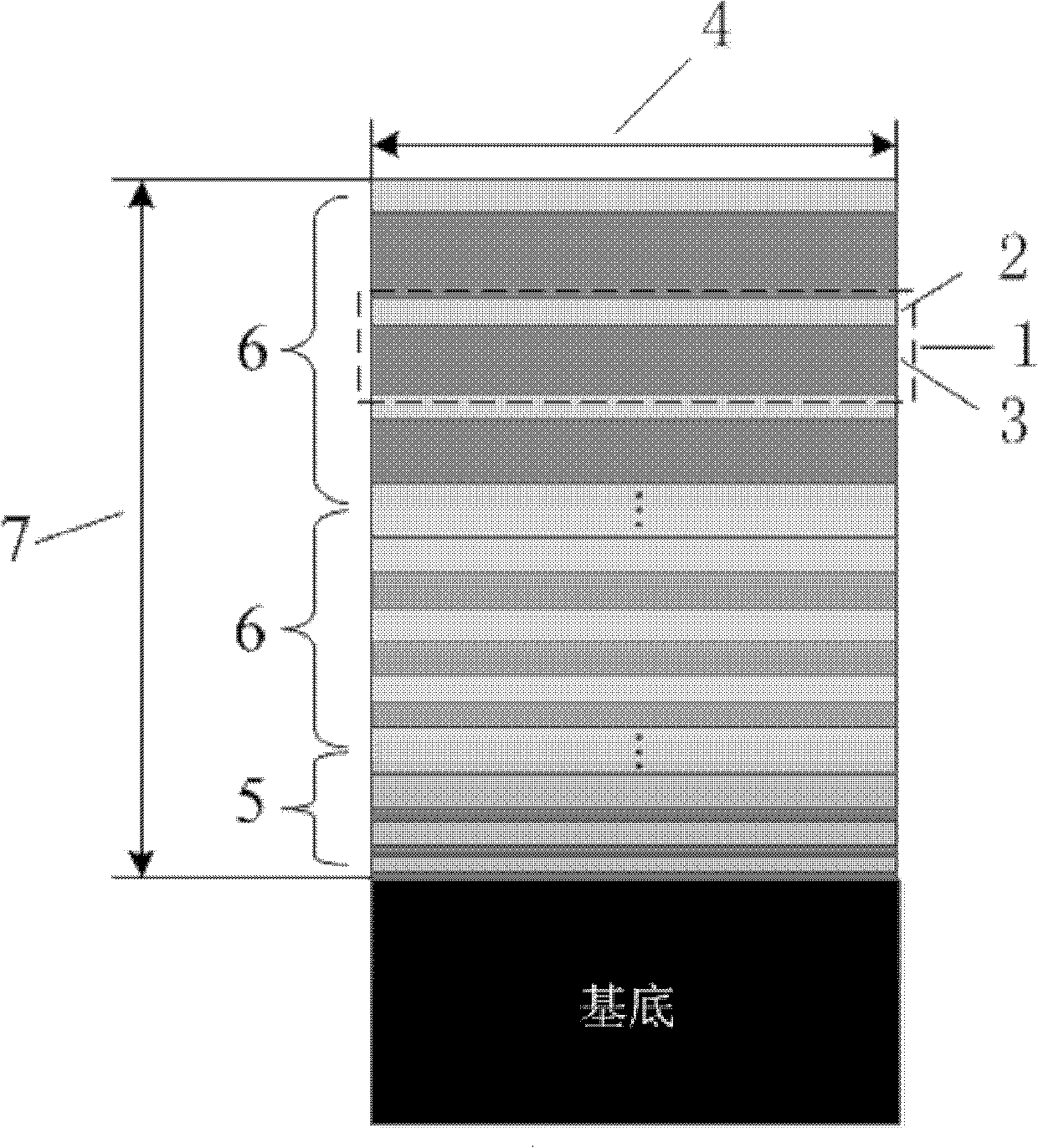

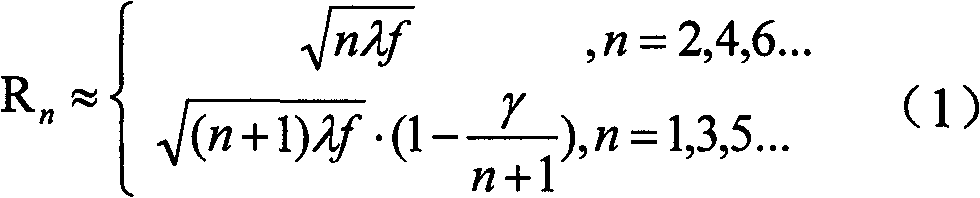

[0032] Such as figure 1 As shown, the multilayer Laue lens can be regarded as composed of a series of periodic partial gratings 1, and the materials of the spacer layer and the absorption layer of the partial gratings are Si layer 2 and WSi 2 For layer 3, the thickness ratio is the ratio of the thickness of Si layer 2 to the period of the grating. The thickness ratio of all local gratings in the ordinary Laue lens structure is 0.5, and the stress of the film system is relatively large, so it is difficult to increase the total thickness of 7. Therefore, a new type of WSi 2 / Si multi-thickness ratio composite multilayer Laue lens design. The resolution of the Laue lens is determined by the outermost film layer. At the same time, because the Laue lens is used in the hard X-ray band, the depth 4 is very large, so the local grating in the outer area 5 belongs to the dynamic diffraction area. The larger the thickness ratio, the better the diffraction efficiency. The higher the va...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com