Multi-temperature zone integrated heat sink

An integrated, radiator technology, applied in indirect heat exchangers, heat exchanger types, heat exchanger shells, etc., can solve problems such as thermal fatigue failure, reduce thermal stress, meet lightweight design, and reduce installation effect of space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

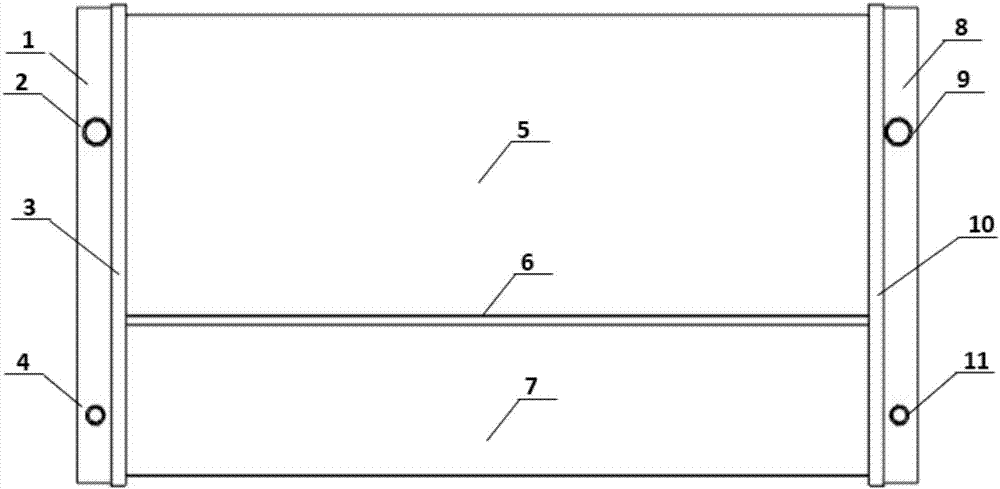

[0022] Such as figure 1 As shown, the multi-temperature zone integrated radiator of the present invention includes a high-temperature heat dissipation module and a low-temperature heat dissipation module, a water inlet chamber 1, a high-temperature water inlet 2, a left main piece 3, a low-temperature water inlet 4, a high-temperature core body 5, a partition Plate 6, low temperature core body 7, water outlet chamber 8, high temperature water outlet 9, right main piece 10 and low temperature water outlet 11. The specific structure and connection relationship are:

[0023] The high temperature heat dissipation module is composed of water inlet chamber 1, high temperature water inlet 2, left main piece 3, high temperature core body 5, water outlet chamber 8, high temperature water outlet 9 and right main piece 10; the low temperature heat dissipation module is composed of water inlet chamber 1, The low temperature water inlet 4, the left main piece 3, the low temperature core b...

Embodiment 2

[0027] This embodiment is an example of a one-piece radiator partition.

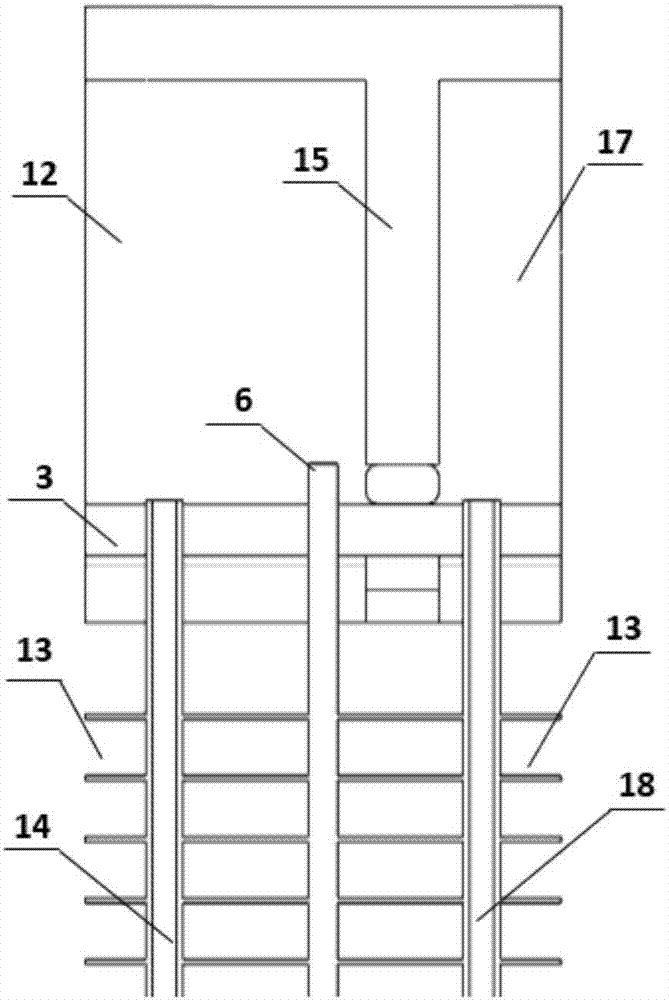

[0028] Such as figure 2 As shown, the separator of the multi-temperature zone integrated radiator of the present invention. The water inlet chamber 1 is divided into two parts, the high temperature zone 12 of the water inlet chamber and the low temperature zone 17 of the water inlet chamber, by the partition plate 15 of the water chamber. The water chamber partition 15 ensures that the cooling liquids in the high and low temperature heat dissipation modules do not mix. There is a partition 6 between the high-temperature cooling pipe 14 on one side of the high-temperature heat dissipation module and the low-temperature cooling pipe 18 on one side of the low-temperature heat dissipation module. There is a heat dissipation belt 13 between the high-temperature cooling pipe 14 , the low-temperature cooling pipe 18 and the partition plate 6 . The dividing plate 6 increases the distance between the high-tem...

Embodiment 3

[0030] This embodiment is an example of the way of connecting the separator and the main sheet.

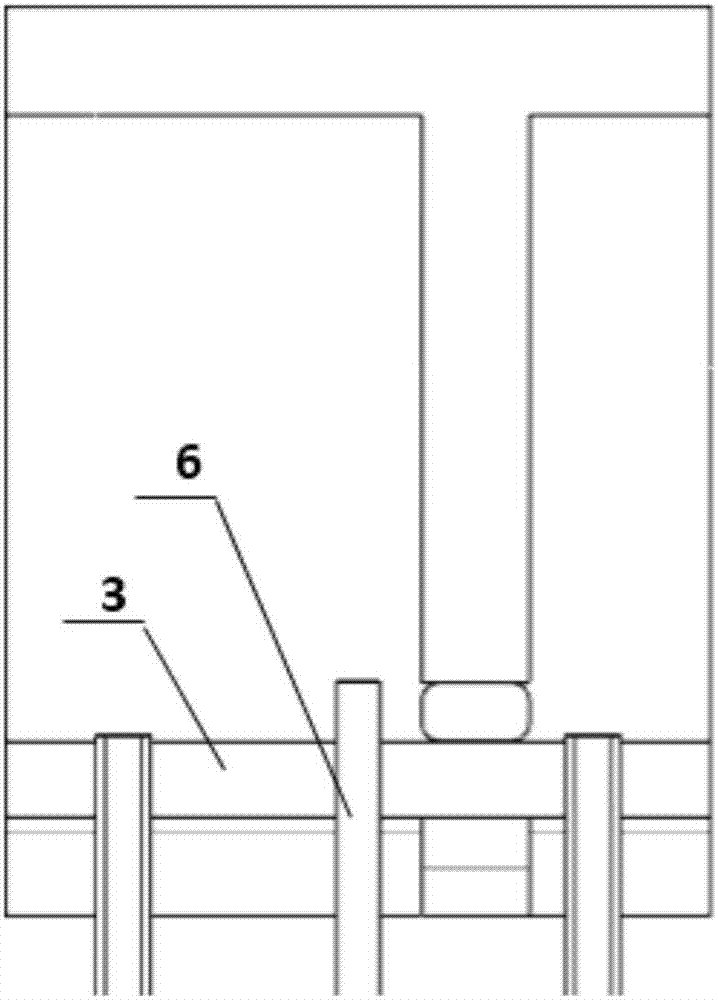

[0031] Such as image 3 As shown, the connection between the partition 6 and the left main piece 3 is plug-in, that is, the head of the partition 6 passes through the left main piece 3 and is connected into one body by brazing.

[0032] Such as Figure 4 As shown, the connection mode of the partition 6 and the left main sheet 3 is an overlapping type, that is, the end of the partition 6 is in contact with the surface of the left main sheet 3 . The two are joined together by brazing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com