Electrospinning direct-writing jet-printing device enhancing focusing function by virtue of double layers of air

A technology of electrospinning direct writing and gas nozzles, which is applied in textiles and papermaking, spinneret assemblies, fiber processing, etc. It can solve the problems of difficult nozzle device simplification and integrated control, unfavorable regulation, etc., and achieve the suppression of jet instability Effects of motion, improved jetting efficiency, and enhanced focus constraints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

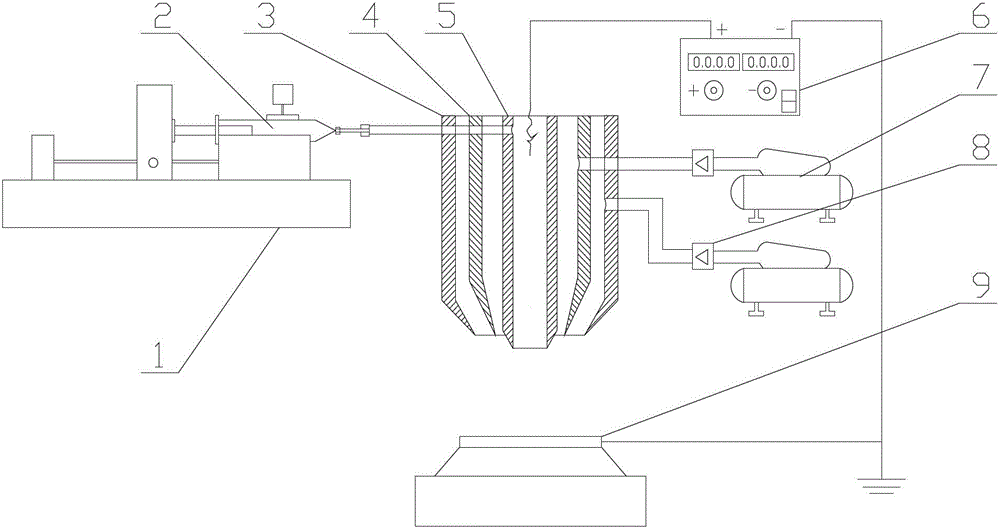

[0016] see figure 1 , the embodiment of the present invention includes a liquid supply device, a solution tank, a nozzle device, a high-voltage power supply 6, an air supply device 7 (two independent air compressors) and a collecting plate 9.

[0017] The nozzle device is provided with an outer gas nozzle 3, an inner gas nozzle 4 and a liquid nozzle 5; the outer gas nozzle 3, the inner gas nozzle 4 and the liquid nozzle 5 are provided with a coaxial central through hole, and the liquid nozzle 5 is arranged in the inner In the central through hole of the gas nozzle 4 , the inner layer gas nozzle 4 is arranged in the central through hole of the outer layer gas nozzle 3 . The outer layer gas nozzle 3 is provided with a radial air inlet, the inner layer gas nozzle 4 is provided with a radial air inlet, and the liquid nozzle 5 is provided with a radial liquid inlet hole. The liquid supply device 1 adopts a precision syringe pump, the solution tank 2 is arranged on the liquid suppl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com