Method for preparing aerogel by quickly dissolving lignocellulose

A lignocellulose and aerogel technology, which is applied in the field of aerogel preparation, can solve the problems of slow dissolution speed and long preparation period, and achieve the effects of low cost, environmental protection and green cost, and wide source of raw materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

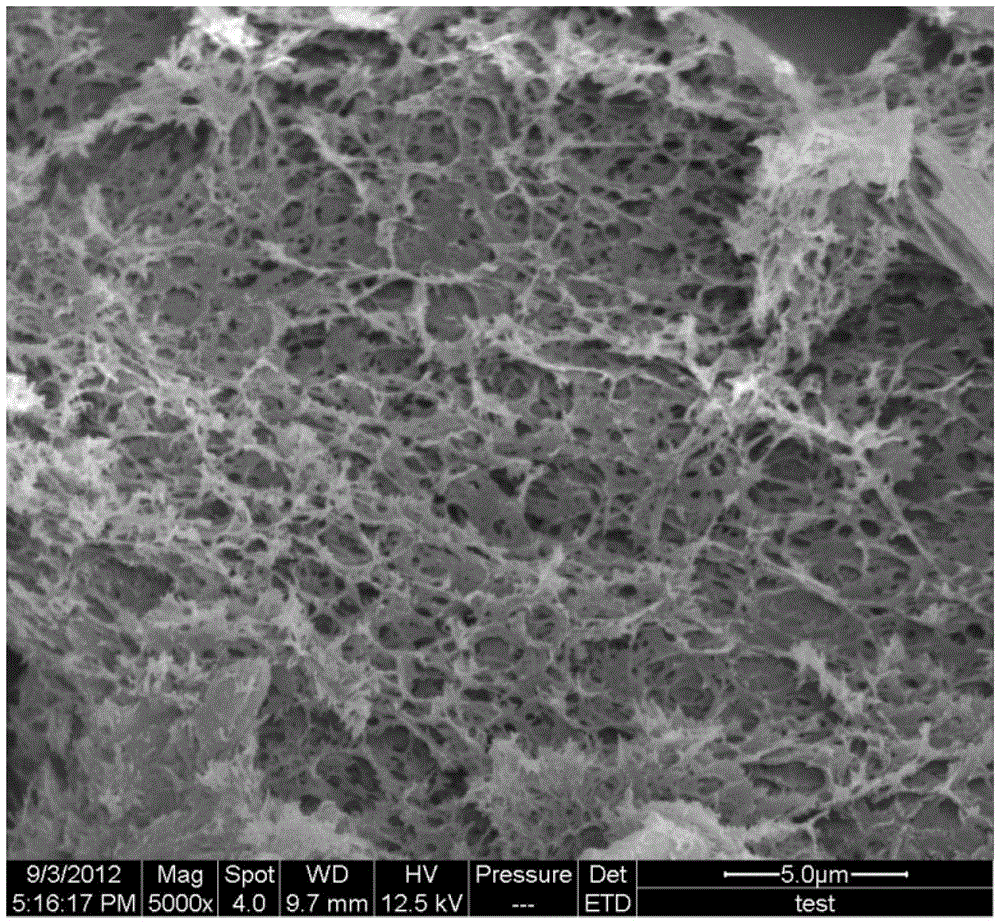

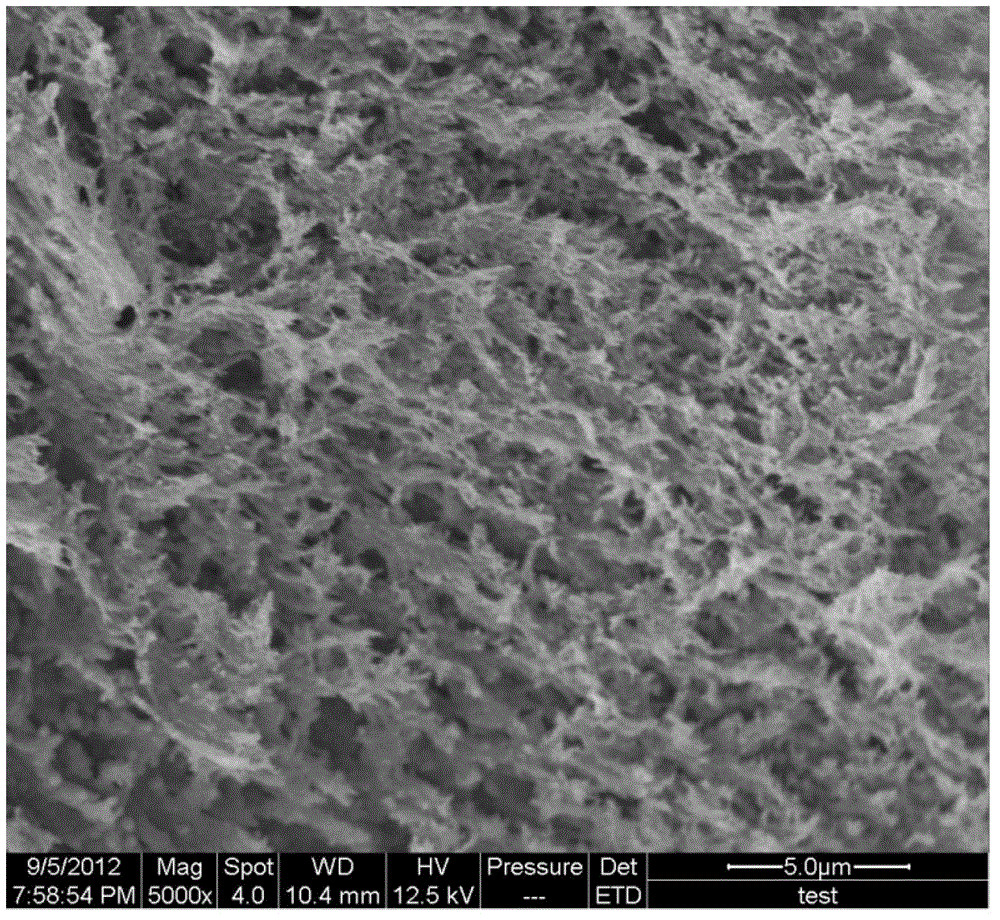

Image

Examples

specific Embodiment approach 1

[0020] Embodiment 1: A method for rapidly dissolving lignocellulose to prepare airgel according to the present embodiment is specifically carried out in the following steps:

[0021] 1. Take the lignocellulosic raw material, wash and remove impurities, dry and pulverize, pass through a 40-200 mesh screen, then mix the lignocellulose raw material and the ionic liquid in a mass ratio of 0.1-20:100, and heat to After stirring at 150-200° C. for 5-20 minutes, a lignocellulose solution is obtained; 2. cooling the above solution; 3. adding a non-solvent to the lignocellulose solution cooled in step 2 to obtain a gel; 4. obtaining a gel in step 3 The lignocellulose aerogel is obtained after the gel is subjected to critical point drying, supercritical drying or freeze drying.

[0022] This embodiment has the following beneficial effects:

[0023] 1. The dissolving efficiency of the lignocellulose aerogel prepared by the existing method in the ionic liquid is low, at least 4 hours or ...

specific Embodiment approach 2

[0028] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the lignocellulosic raw material described in step 1 is a biomass raw material containing lignin, wherein the biomass raw material containing lignin includes wood waste, papermaking Residues, inedible parts of crops or resource crops. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0029] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the lignocellulose raw material and the ionic liquid described in step 1 are mixed in a mass ratio of 0.5-15:100. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com