Method for separating active ingredients from aquilaria sinensis lamina by utilizing high-speed countercurrent chromatography

A high-speed countercurrent chromatography, active ingredient technology, applied in the field of separation of anticancer and antioxidant active ingredients from leaves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

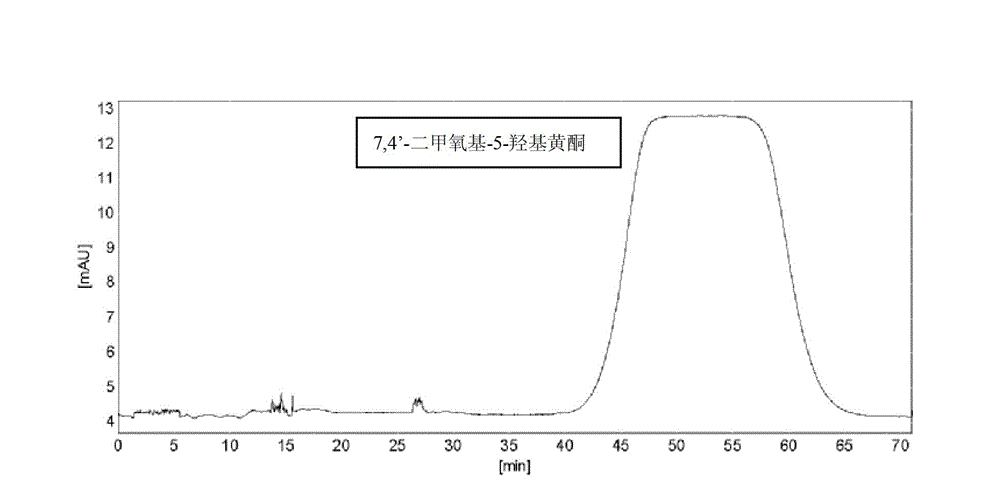

[0068] The active ingredient A was isolated from petroleum ether part extract (sample I):

[0069] 1. Prepare 1000mL of n-hexane:ethyl acetate:methanol:water (V / V)=1:1.5:1.5:1 solvent system, fully shake and mix, then stand and separate to obtain upper and lower phase solutions, and then The upper and lower phases were separated and ultrasonically degassed for 30 minutes before use;

[0070] 2. The upper phase solution is used as the mobile phase, and the lower phase solution is the stationary phase. Turn on the injection pump to pump the stationary phase into the maximum flow rate of the equipment and fill the countercurrent chromatographic column, and then turn on the high-speed countercurrent chromatographic host, detector, and chromatographic workstation. Pump the mobile phase at a speed of 815rpm and a flow rate of 1.0ml / min;

[0071] 3. Take 50.0mg of sample I and dissolve it in 20ml lower phase in a test tube until completely dissolved;

[0072] 4. After the curve of ...

Embodiment 2

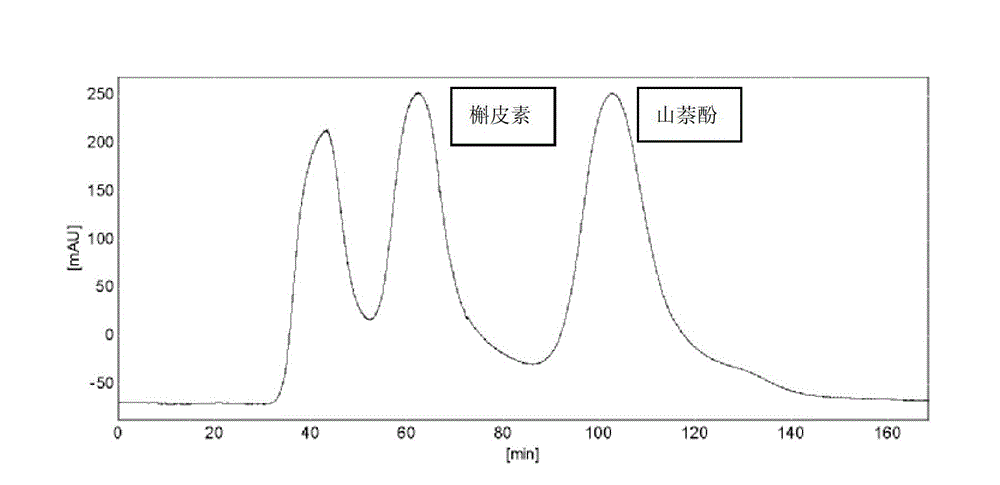

[0103] The active ingredients A, B, and C are separated by countercurrent chromatographic separation using the extract of ethyl acetate, and the solvent system is firstly n-hexane:ethyl acetate:methanol:water (V / V)=1.5:2:2:1.5 Isolate the active component A by the separation method of petroleum ether extract in Example 1, then use silica gel column chromatography to roughly separate the ethyl acetate extract to obtain the crude extract containing the target component, and finally use normal hexane: ethyl acetate: methanol: Water (V / V)=0.5:1:1:0.5 is the solvent system to separate the active components B and C.

[0104] Wherein the parameter of high-speed countercurrent chromatographic separation active component A is:

[0105] The high-speed countercurrent chromatography host rotates clockwise at a speed of 900rpm; the sample volume is 60.0mg, the retention value of the stationary phase is 73.0%, and the flow rate of the mobile phase is 1.2ml / min; the detection wavelength is 2...

Embodiment 3

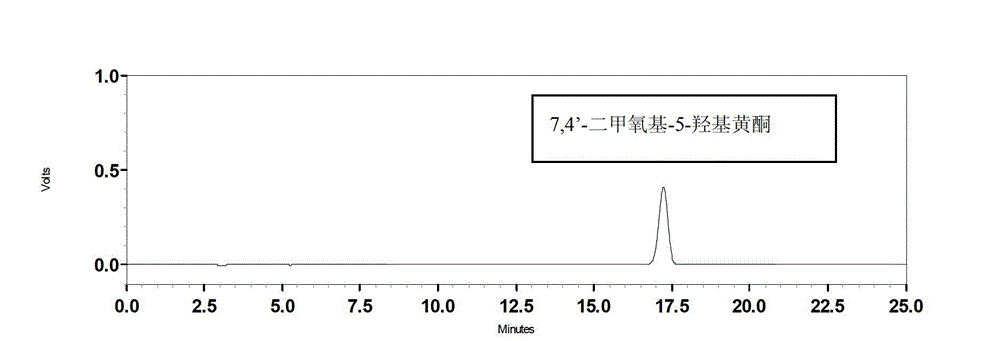

[0112] The active ingredient A is separated from petroleum ether extract and ethyl acetate extract by high-speed countercurrent chromatography, and its parameters are:

[0113] The main engine of high-speed countercurrent chromatography rotates clockwise at 750rpm; the sample volume is 40.0mg, the retention value of the stationary phase is 65.4%, the flow rate of the mobile phase is 0.8ml / min; the detection wavelength is 254nm; the separation temperature is 17~23°C;

[0114] Then the ethyl acetate extract is roughly separated by silica gel column chromatography, and the fraction containing the target component is retained as a crude extract, and finally the crude extract is subjected to high-speed countercurrent chromatography to obtain active ingredient B and active ingredient C. Wherein the separation parameters of high-speed countercurrent chromatography are:

[0115] The main engine of high-speed countercurrent chromatography rotates clockwise at 750rpm; the sample volume ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com