Method for producing dicumyl peroxide

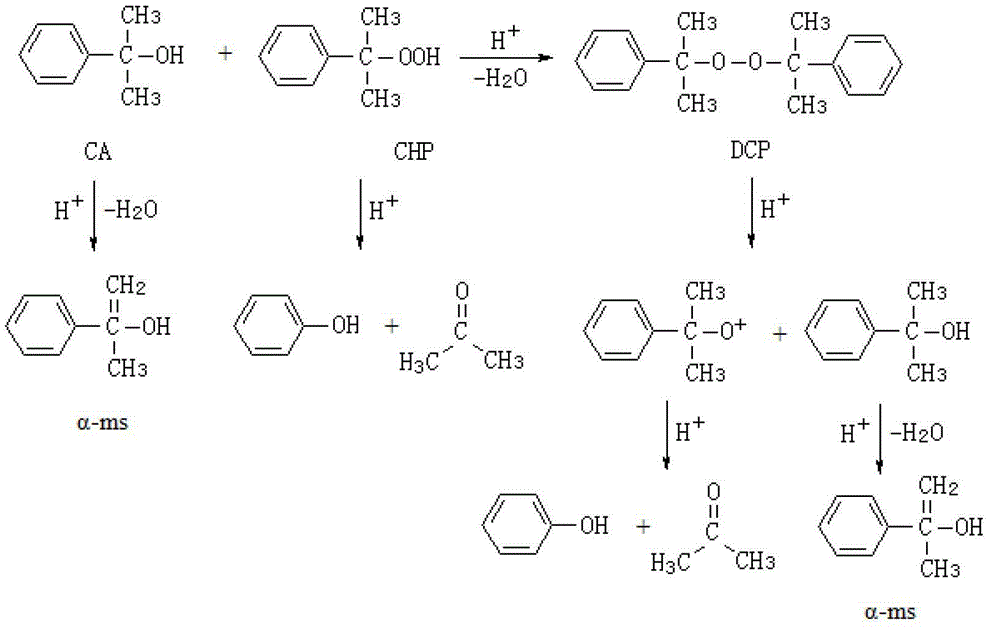

A technology of dicumyl peroxide and cumene hydroperoxide, which is applied in the production field of reducing dicumyl peroxide condensation by-products, can solve the problem of by-product α-MS, and achieve the reduction of α-MS, The effect of reducing by-products and reducing unit consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-10

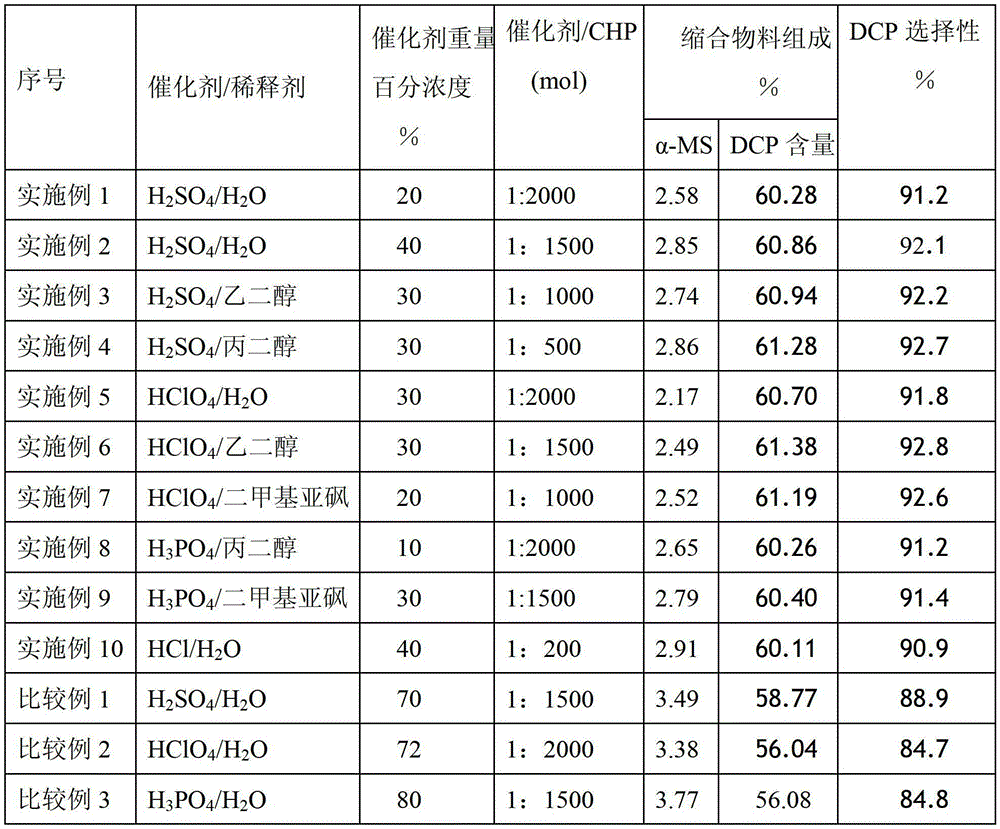

[0020] Embodiment 1-10, comparative example 1-3

[0021] Under heating in a water bath and stirring, first add dimethyl benzyl alcohol (90-95% CA), and then add acid catalysts with different weight percentage concentrations, or acid catalysts and diluents into the reactor respectively, and then Add cumene hydroperoxide (45-65% CHP). Turn on the vacuum pump to make the pressure of the reaction system reach the required value, and the water generated by the reaction is pumped out of the reaction bottle through decompression bubbling to make the reaction proceed smoothly. The reaction temperature is 35-45°C, the gauge pressure is -0.10~-0.05MPa, the ratio of the main reaction materials is 1:1, and the solvent cumene is brought from cumene hydroperoxide oxidation solution and dimethyl benzyl alcohol. No additional solvent is needed, and the solvent accounts for about 35-40% of the condensed liquid. Other reaction conditions and results are shown in Table 2.

[0022] Table 2 Eff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com