Clinker-free compound-type tailing consolidating agent as well as preparation and application for same

A cementing agent and composite technology, which can be used in clinker production, waste reduction, cement production, etc., can solve the problems of inconvenient popularization and application, complex production process, high cost, low production cost, avoid high pollution, early stage high intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

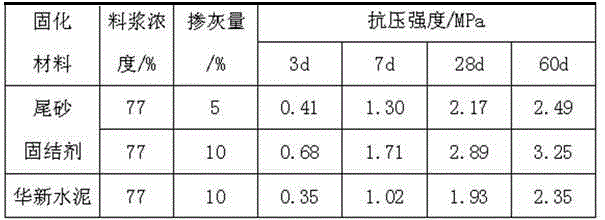

Embodiment 1

[0026] The clinker-free composite tailings consolidation agent has the following composition by weight: 68% slag, 25% desulfurization ash, and 7% composite activator.

[0027] Among them, the slag is the raw material obtained by drying the waste slag discharged from the blast furnace of the iron and steel smelter after water quenching, and its moisture content is 0.76%; the desulfurization ash is the desulfurization by-product produced by the flue gas desulfurization process of the coal-fired power plant after drying. Dry the raw material obtained, and detect that its water content is 0.65%; each component in the composite activator is: quicklime 63%, anhydrous gypsum 35%, ZnCl 2 2%.

[0028] Preparation steps: Put all the slag, desulfurization ash, and composite activator into the ball mill, and grind for 1 hour under the condition of the material-ball ratio of 1:10, until the specific surface area is not less than 400m 2 / kg of tailings consolidation agent.

[0029] Tailin...

Embodiment 2

[0034] The clinker-free composite tailings consolidation agent has the following composition by weight: 60% slag, 35% desulfurization ash, and 5% composite activator.

[0035] Among them, the slag is the raw material obtained by drying the waste slag discharged from the blast furnace of the iron and steel smelter after water quenching, and its moisture content is 0.58%; the desulfurization ash is the desulfurization by-product produced by the flue gas desulfurization process of the coal-fired power plant after drying. Dry the raw material obtained, and detect that its water content is 0.77%; each component in the composite activator is: slaked lime 55%, dihydrate gypsum 40%, KCl 2% and CaCl 2 3%.

[0036] The preparation steps are as follows: put all the slag, desulfurization ash, and composite activator into the ball mill, and grind for 1.5 hours under the condition of the material-ball ratio of 1:9 until the specific surface area is not less than 400m 2 / kg of tailings cons...

Embodiment 3

[0042] The clinker-free composite tailings consolidation agent has the following composition by weight: 55% slag, 39% desulfurization ash, and 6% composite activator.

[0043]Among them, the slag is the raw material obtained by drying the waste slag discharged from the blast furnace of the iron and steel smelter after water quenching, and its moisture content is detected to be 0.65%; Dry the raw material that obtains, detect its water content and be 0.80%; Each component is in the compound activator: slaked lime 40%, Na 2 CO 3 15%, alum 25%, anhydrite 15%, CaCl 2 5%.

[0044] The preparation steps are as follows: put all the slag, desulfurization ash, and composite activator into the ball mill, and grind for 1.2 hours under the condition of the material-ball ratio of 1:11 until the specific surface area is not less than 400m 2 / kg of tailings consolidation agent.

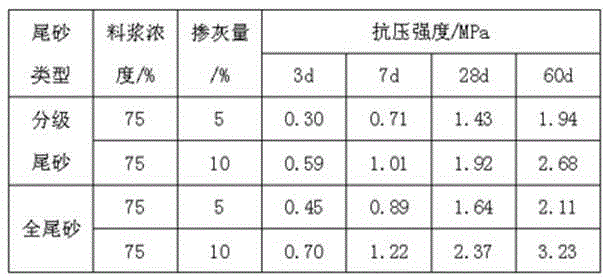

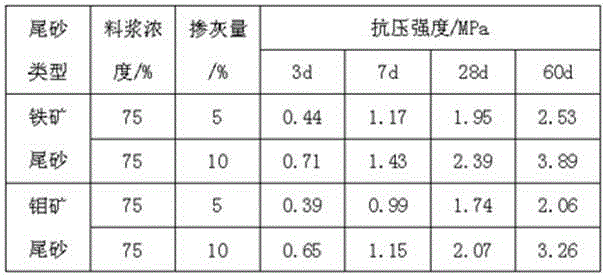

[0045] Tailings Consolidation Experiment: Mix the graded tailings (from the tailings classification station) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com