Hydroxide solid pipeline dredging maintenance agent and its preparation technology

A hydroxide and preparation technology, applied in the direction of surface-active non-soap compounds and washing compositions, cleaning hollow objects, detergent compositions, etc., can solve the impact on the environment and human health, high proportion of active ingredients, dredging effect Weaken and other problems, to achieve the effect of low component price, low cost, and large economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

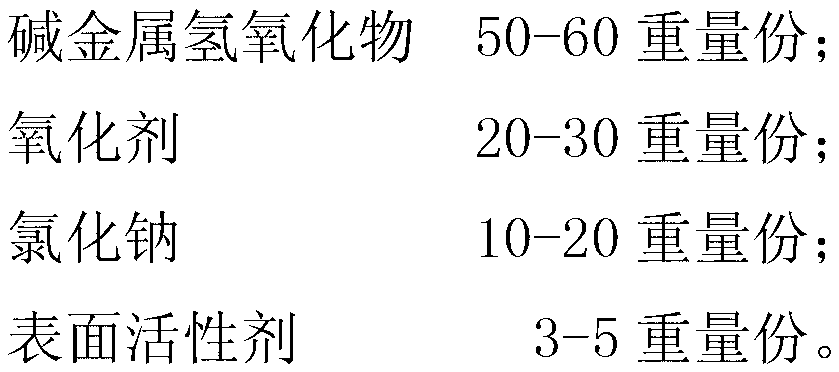

[0026] A kind of hydroxide solid pipe dredging maintenance agent, it is made of the following components by weight:

[0027]

[0028] The formulation of this embodiment is suitable for dredging pipelines with less blockage.

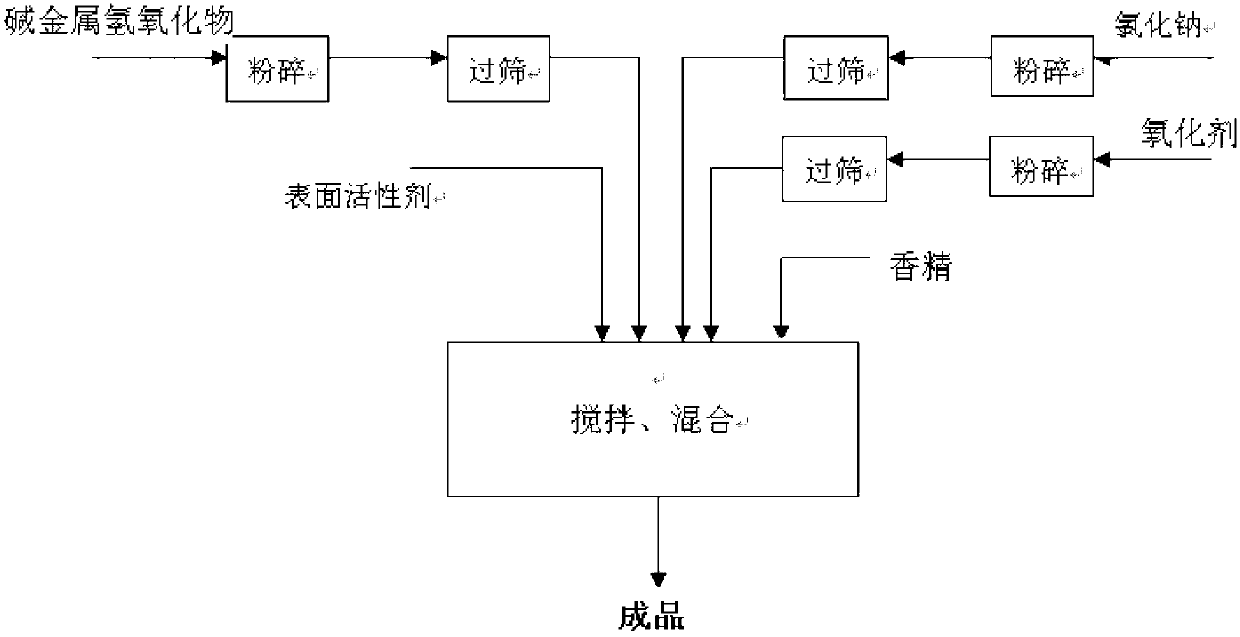

[0029] The preparation method of the above-mentioned hydroxide solid pipeline dredging and maintenance agent is: sequentially weighing and measuring the above-mentioned solid components granular sodium hydroxide, sodium chloride, sodium persulfate and sodium lauryl sulfate. The sodium hydroxide is pulverized and then sieved, the sodium chloride is pulverized and then sieved, and the sodium persulfate is pulverized and then sieved. Stir and mix the above sodium hydroxide, sodium chloride, sodium persulfate and sodium lauryl sulfate evenly to make a finished product.

Embodiment 2

[0031] A kind of hydroxide solid pipe dredging maintenance agent, it is made of the following components by weight:

[0032]

[0033] The formulation of this embodiment is suitable for dredging pipelines with severe blockage.

[0034] The preparation method of the above-mentioned hydroxide solid pipeline dredging and maintenance agent is: sequentially weighing and measuring the above-mentioned solid components granular sodium hydroxide, sodium chloride, sodium persulfate and sodium lauryl sulfate. The sodium hydroxide is pulverized and then sieved, the sodium chloride is pulverized and then sieved, and the sodium persulfate is pulverized and then sieved. Stir and mix the above sodium hydroxide, sodium chloride, sodium persulfate and sodium lauryl sulfate evenly to make a finished product.

Embodiment 3

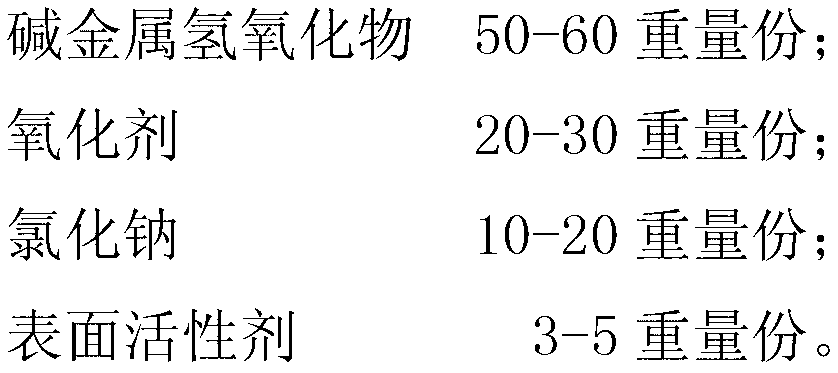

[0036] A kind of hydroxide solid pipe dredging maintenance agent, it is made of the following components by weight:

[0037]

[0038] The preparation method of the above-mentioned hydroxide solid pipeline dredging and maintenance agent is: sequentially weighing and measuring the above-mentioned solid components granular potassium hydroxide, sodium chloride, sodium percarbonate and sodium dodecylbenzenesulfonate. Potassium hydroxide is pulverized and then sieved, sodium chloride is pulverized and then sieved, and sodium percarbonate is pulverized and then sieved. Stir and mix the above potassium hydroxide, sodium chloride, sodium percarbonate, sodium dodecylbenzenesulfonate and methyl cinnamic acid evenly to make a finished product.

[0039] The using method of the solid pipeline dredging curing agent of the present invention is:

[0040] When dredging a blocked drainage pipe, you can directly put 100 grams of the solid pipe dredging agent of the present invention into the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com