Preparation of natural polymer base hemostasis dressing

A natural polymer, hemostatic dressing technology, applied in the fields of medical science, absorbent pads, bandages, etc., can solve the problems such as the effect to be improved, and achieve the effect of good air permeability, good hemostatic effect, and good wound protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 1) Dissolve chitosan (Mw=50000g / mol) directly in a mixed solution of deionized water and formic acid (FA), prepare a solution with a concentration of 5wt%, and stir at room temperature until completely dissolved;

[0022] 2) Dissolve hyaluronic acid (Mw=500000g / mol) directly in deionized water to prepare a solution with a concentration of 0.05wt%, and stir at room temperature until completely dissolved;

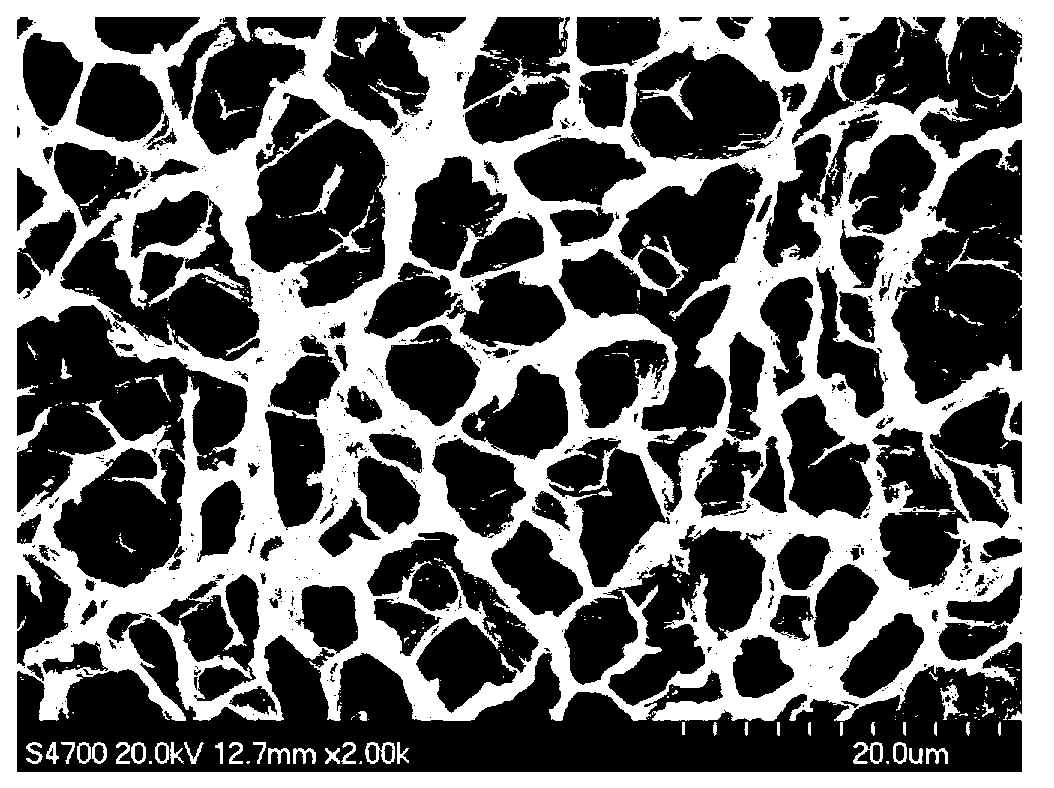

[0023] 3) Transfer the chitosan solution prepared in step 1) to a liquid nitrogen freezing device, turn on the freezing device, freeze the prepared chitosan solution in a liquid nitrogen environment, and then transfer the frozen chitosan solution to In the freeze dryer, under the conditions of temperature ~-80°C and vacuum degree ~1Pa, carry out freeze-drying treatment for more than 48 hours to obtain a "honeycomb" chitosan fiber membrane; (see figure 1 )

[0024] 4) Pour the hyaluronic acid solution prepared in step 2) on the chitosan fiber membrane, and add a small ...

Embodiment 2

[0027] 1) Dissolve chitosan (Mw=100000g / mol) directly in a mixed solution of deionized water and formic acid (FA), prepare a solution with a concentration of 3wt%, and stir at room temperature until completely dissolved;

[0028] 2) Dissolve hyaluronic acid (Mw=1000000g / mol) directly in deionized water to prepare a solution with a concentration of 0.03wt%, and stir at room temperature until completely dissolved;

[0029] 3) Transfer the chitosan solution prepared in step 1) to a liquid nitrogen freezing device, turn on the freezing device, freeze the prepared chitosan solution in a liquid nitrogen environment, and then transfer the frozen chitosan solution to In the freeze dryer, under the condition of temperature ~-80℃ and vacuum degree ~1Pa, carry out freeze-drying treatment for more than 48 hours to obtain a "honeycomb" chitosan fiber membrane;

[0030] 4) Pour the hyaluronic acid solution prepared in step 2) on the chitosan fiber membrane, and add a small amount of thrombi...

Embodiment 3

[0033] 1) Dissolve chitosan (Mw=200000g / mol) directly in a mixed solution of deionized water and formic acid (FA), prepare a solution with a concentration of 1wt%, and stir at room temperature until completely dissolved;

[0034] 2) Dissolve hyaluronic acid (Mw=2000000g / mol) directly in deionized water to prepare a solution with a concentration of 0.01wt%, and stir at room temperature until completely dissolved;

[0035] 3) Transfer the chitosan solution prepared in step 1) to a liquid nitrogen freezing device, turn on the freezing device, freeze the prepared chitosan solution in a liquid nitrogen environment, and then transfer the frozen chitosan solution to In the freeze dryer, under the condition of temperature ~-80℃ and vacuum degree ~1Pa, carry out freeze-drying treatment for more than 48 hours to obtain a "honeycomb" chitosan fiber membrane;

[0036] 4) Pour the hyaluronic acid solution prepared in step 2) on the chitosan fiber membrane, and add a small amount of thrombi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com