Nanometer adsorption material and preparation method thereof

A nano-adsorbent material and composite material technology, applied in chemical instruments and methods, adsorbed water/sewage treatment, other chemical processes, etc., can solve the problem that the adsorption material is not easy to recycle and reuse, the price of ion exchange resin is high, and the selectivity of activated carbon is poor, etc. problem, to achieve fast adsorption rate, avoid secondary pollution, good regeneration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The present invention also provides the preparation method of this nano adsorption material, comprises the following steps:

[0026] a) One-step synthesis of Fe3O4 / graphene composites by solution method: in N 2 FeCl 3 and FeCl 2 Add it into the graphene oxide solution, adjust the pH to 9-11, preferably adjust it with ammonia water at a temperature of 60°C to 80°C, then add a hydrazine hydrate solution for reduction, preferably react at a temperature of 80°C to 100°C.

[0027] where FeCl 3 with FeCl 2 The molar ratio of is preferably 1.5-3:1.

[0028] The concentration of graphene oxide solution is selected from 0.5 mg / mL to 1.5 mg / mL. Graphene oxide can be synthesized by common Hummers chemical method, see Hummers, W.S, et al.J.Am.Chem.Soc., 1958, 80: 1339, or purchase existing graphene oxide products on the market. The addition of graphene oxide can greatly improve the overall adsorption performance of the adsorption material and enhance the stability and mechani...

Embodiment 1

[0034] a) at N 2 FeCl with a molar ratio of 2:1 was 3 and FeCl 2 Add it to the graphene oxide solution with a concentration of 1mg / mL, adjust the pH to 10 with ammonia water at 80°C, and then add a hydrazine hydrate solution with a mass percent concentration of 30% at 90°C for reaction reduction, and add the hydrazine hydrate solution The amount is 20 mL / (g graphene oxide).

[0035] b) Combine the above-prepared ferric oxide / graphene composite suspension with magnesium chloride hexahydrate at a concentration of 0.15mmol / mL, aluminum chloride hexahydrate at 0.06mmol / mL and hexamethylene chloride at a concentration of 0.3mmol / mL The aqueous solution of base tetramine was mixed, put into a hydrothermal kettle for hydrothermal reaction at 100° C., and reacted for 12 hours to obtain ferric oxide / graphene / magnesium aluminum double hydroxide composite material.

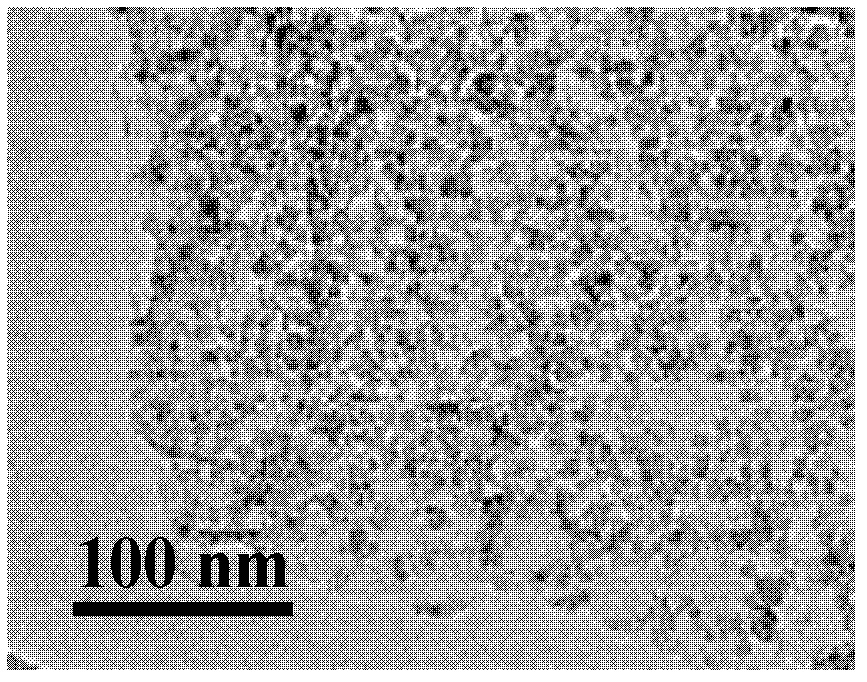

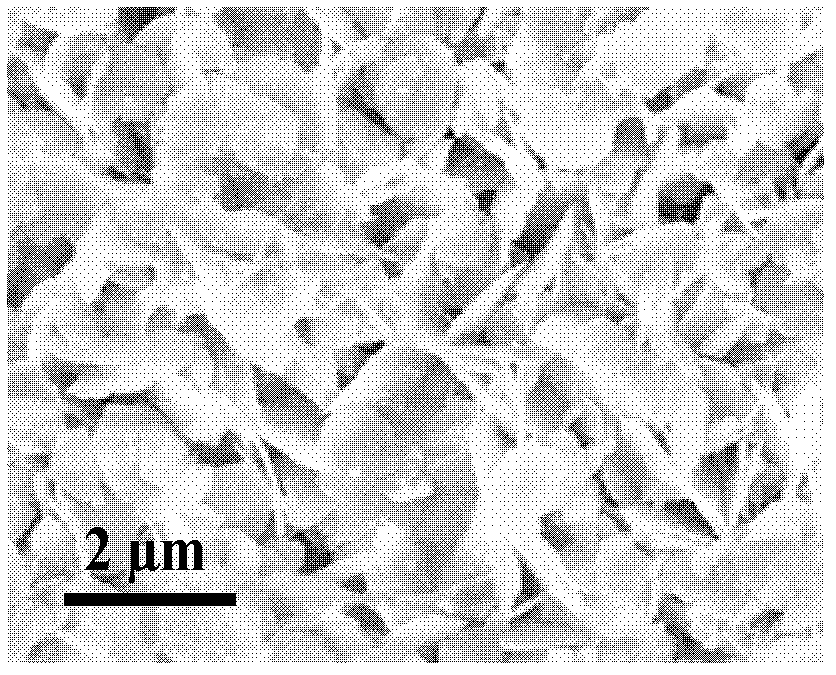

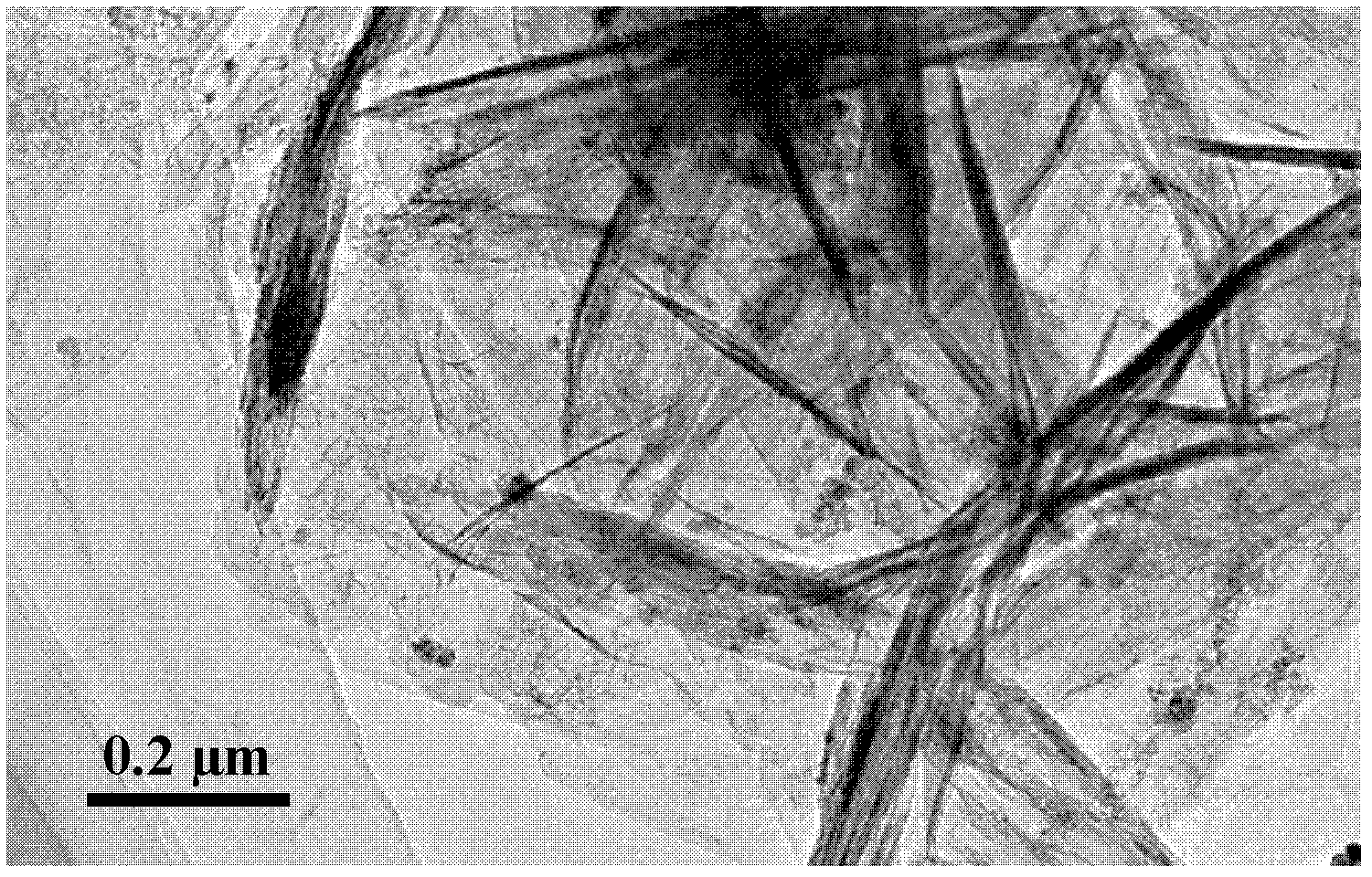

[0036] The molar ratio of each element in the reactant is Fe:Mg:Al:C=0.27:0.50:0.28:0.39. The microstructure of the pr...

Embodiment 2

[0038]a) at N 2 FeCl with a molar ratio of 1.5:1 was 3 and FeCl 2 Add it to a graphene oxide solution with a concentration of 0.8mg / mL, adjust the pH to 9 with ammonia water at 60°C, and then add a hydrazine hydrate solution with a mass percent concentration of 35% at 85°C for reaction reduction, the hydrazine hydrate solution The addition amount is 15mL / (g graphene oxide).

[0039] b) Combine the above-prepared ferric oxide / graphene composite suspension with magnesium chloride hexahydrate, 0.07 mmol / mL aluminum chloride hexahydrate and 0.25 mmol / mL hexamethylene chloride at a concentration of 0.1 mmol / mL The aqueous solution of base tetramine was mixed, put into a hydrothermal kettle for hydrothermal reaction at 110° C., and reacted for 10 hours to obtain ferric oxide / graphene / magnesium aluminum double hydroxide composite material.

[0040] The molar ratio of each element in the reactant is Fe:Mg:Al:C=0.2:0.40:0.3:0.5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com