Egg-contained dry food

A technology for drying food and eggs, applied in food preparation, food science, applications, etc., can solve problems such as poor water absorption and expansion, poor floatability, and poor taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

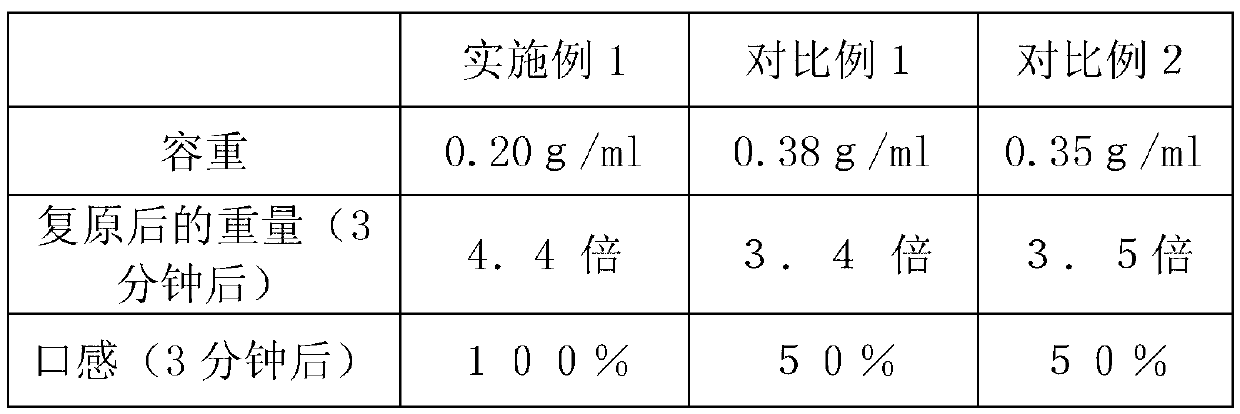

Embodiment 1

[0016] Take 3500 parts by weight of egg powder, 1000 parts of starch, 500 parts of granulated sugar, 200 parts of vegetable oil, 250 parts of salt, 50 parts of monosodium glutamate, and 1 part of carotene, and then use a 0-30 °C containing puffing agent with a mass concentration of 1 %~10% water is stirred into a dough with a moisture content of 10%, and then granulated by a granulator, then heated to a temperature above 85°C by microwave at 500J / g and 10-60 seconds and dried to a moisture content of 8% , and then dried under hot air at 50°C to 80°C to a moisture content of 1% and a bulk density of 0.20g / ml.

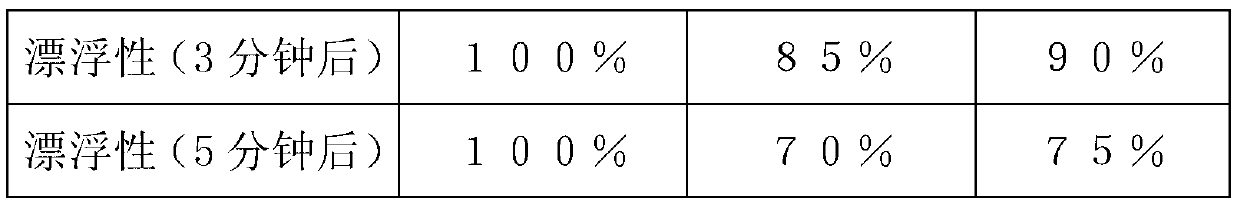

Embodiment 2

[0018] Take 2500 parts by weight of egg powder, 2000 parts of starch, 1000 parts of granulated sugar, 300 parts of vegetable oil, 300 parts of salt, 100 parts of monosodium glutamate, and 3 parts of carotene, and then use a 0-30 °C containing swelling agent with a mass concentration of 1 %~10% water is stirred into a dough with a moisture content of 25%, and then granulated into granules by a granulator, and then heated to a temperature above 85°C by microwave at 1800J / g for 10-60 seconds and dried to a moisture content of 12% , and then dried under hot air at 50°C to 80°C to a moisture content of 5% and a bulk density of 0.24g / ml.

Embodiment 3

[0020] Take 1500 parts by weight of egg powder, 3000 parts of starch, 1500 parts of granulated sugar, 400 parts of vegetable oil, 350 parts of salt, 150 parts of monosodium glutamate, and 5 parts of carotene, and then use a 0-30 °C containing puffing agent with a mass concentration of 1 %~10% water is stirred into a dough with a moisture content of 40%, and then granulated into granules by a granulator, and then heated to a temperature above 85°C by microwave at 3000J / g and 10-60 seconds and dried to a moisture content of 20% , and then dried under hot air at 50°C to 80°C to a moisture content of 8% and a bulk density of 0.30g / ml.

[0021] Product performance comparison

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com