Exhaust fume collecting hood for robot and common welding station

A technology for welding stations and fume collecting hoods, which is applied in the field of fume collecting hoods to achieve the effects of simple structure, reduced quantity and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

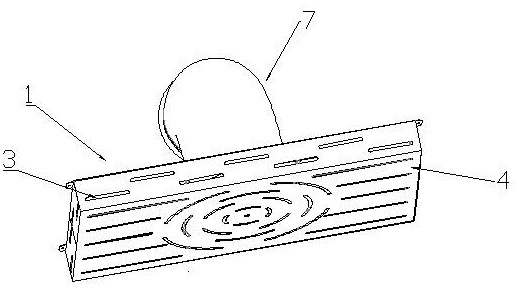

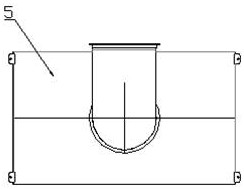

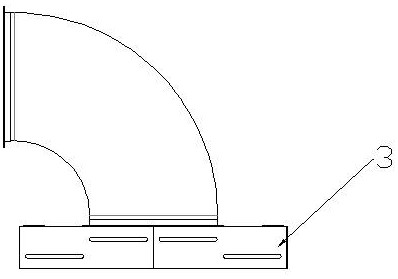

[0022] Such as Figure 1-5 Shown, a kind of fume collecting hood that is used for robot and common welding station, comprises the fume collecting hood main body 1 of rectangular box-type structure, and the four weeks of described fume collecting hood main body 1 are respectively provided with dust recovery holes I 3, wherein the fume collecting The smoke and dust recovery holes I 3 on the front and back of the cover main body 1 are alternately distributed up and down, and the smoke and dust recovery holes I 3 on both sides of the smoke collecting hood main body 1 are symmetrically distributed with the center line of the side of the smoke collecting hood main body 1 as the axis. The inside of the smoke collecting hood main body 1 is provided with a smoke collecting chamber 2, the top and bottom of the smoke collecting chamber 2 are respectively provided with a baffle 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com