Bisultap mother liquor recycling system and process based on membrane treatment technology

A technology of dimehytap and recycling, which is applied in the recycling system and technology field of dimehypo mother liquor, can solve the problems of large discharge pollution, high production cost, low recovery rate, etc., and achieve energy saving, emission reduction, miscellaneous The effect of mass reduction and purity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

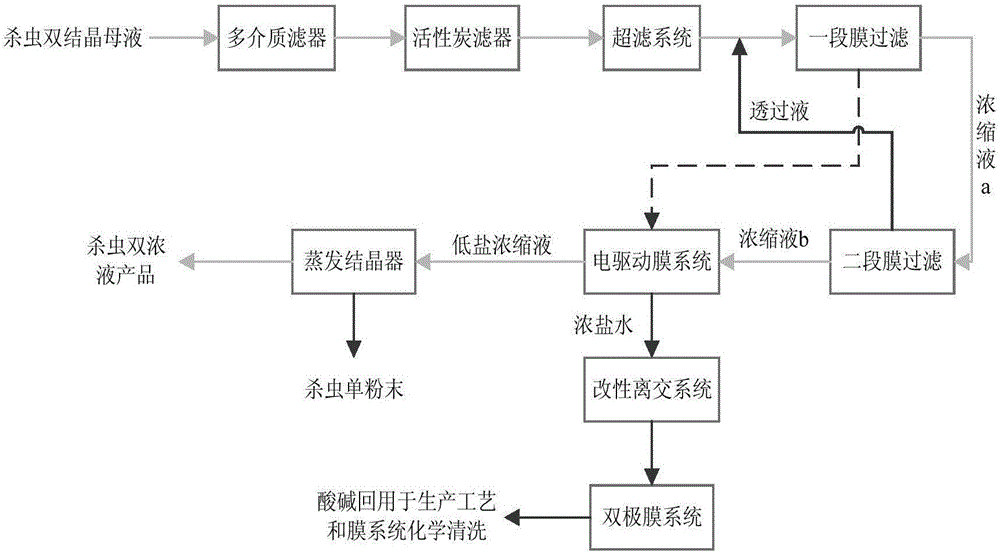

[0046] One embodiment, the dimehypo mother liquor recycling system based on the membrane treatment technology of the present invention includes:

[0047] Filtration equipment, configured to include multi-media filters and activated carbon filters to remove particulate matter and colloidal matter in the mother liquor;

[0048] The ultrafiltration system, connected with the filtration equipment, is used to further purify the product water entering from the filtration equipment;

[0049] The membrane filtration system is connected with the ultrafiltration system and configured to include a two-stage membrane filtration system. The water produced by the ultrafiltration system enters the membrane filtration system, and the concentrated water of one stage of the membrane filtration system in the two-stage membrane filtration system is used as the second stage membrane filtration system. The influent water of the filtration system is filtered again;

[0050] And the electric-driven ...

Embodiment 1

[0059] First, 1000L of dimehypo crystallization mother liquor is filtered through a rationally graded multi-media filter and activated carbon filter to obtain 1000L of filtrate, and then filtered through different brands of ultrafiltration membranes with the same molecular weight cut-off (molecular weight cut-off is 1 to 100,000 Da) to obtain clarification Dimehypo crystallization mother liquor 1000L, the ultrafiltration membrane brand that embodiment 1 adopts has membrane 1, membrane 2, membrane 3.

[0060] Table 1. Data on the clarification effect of different brands of ultrafiltration membranes on dimehypo crystallization mother liquor

[0061] compare items film 1 film 2 film 3 Operating pressure (MPa) 0.12 0.15 0.13 Membrane flux (LMH) 58 48 52 Permeate Turbidity (SDI) 1 1.8 2.4

[0062] Through the analysis of the experimental results of the above-mentioned ultrafiltration membrane, it can be known that the operating pressure o...

Embodiment 2

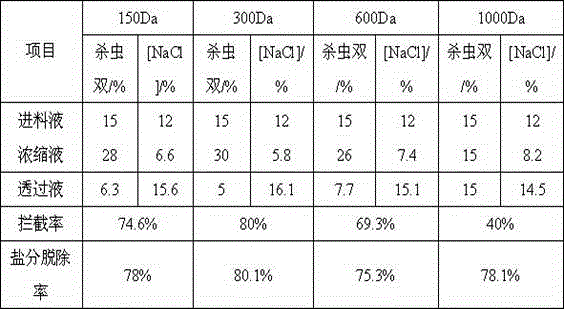

[0064] On the basis of Example 1, the clarified dimehypo crystallization mother liquor was desalted and concentrated using the two-stage nanofiltration process (the recovery rate was 60%). The nanofiltration membrane used in this example had a molecular weight cut-off of 150Da and 300Da respectively. , 600Da and 1000Da, the desalination and concentration effects of the above four molecular weight cut-off nanofiltration membranes were compared and analyzed.

[0065] Table 2. Performance data of dimehypo crystallization mother liquor desalination concentration with different molecular weight cut off

[0066]

[0067] From the above results, it can be found that the nanofiltration membrane with a molecular weight cut-off of 300 Da is the best for the concentration and desalination of the dimehypo crystal mother liquor, the material interception rate of dimehypo is 80%, and the salt removal rate is 80.1%.

[0068] Through Example 2, 400 L of concentrated solution with 30% dimeh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com