Preparation technology of crude amino silicone oil

A preparation process, the technology of amino silicone oil, applied in the field of silicone oil preparation, can solve the problems of rising impurity content, long reaction time, low degree of polymerization, etc., and achieve the effects of high molecular weight uniformity, environmental protection in the preparation process, and controllable molecular weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

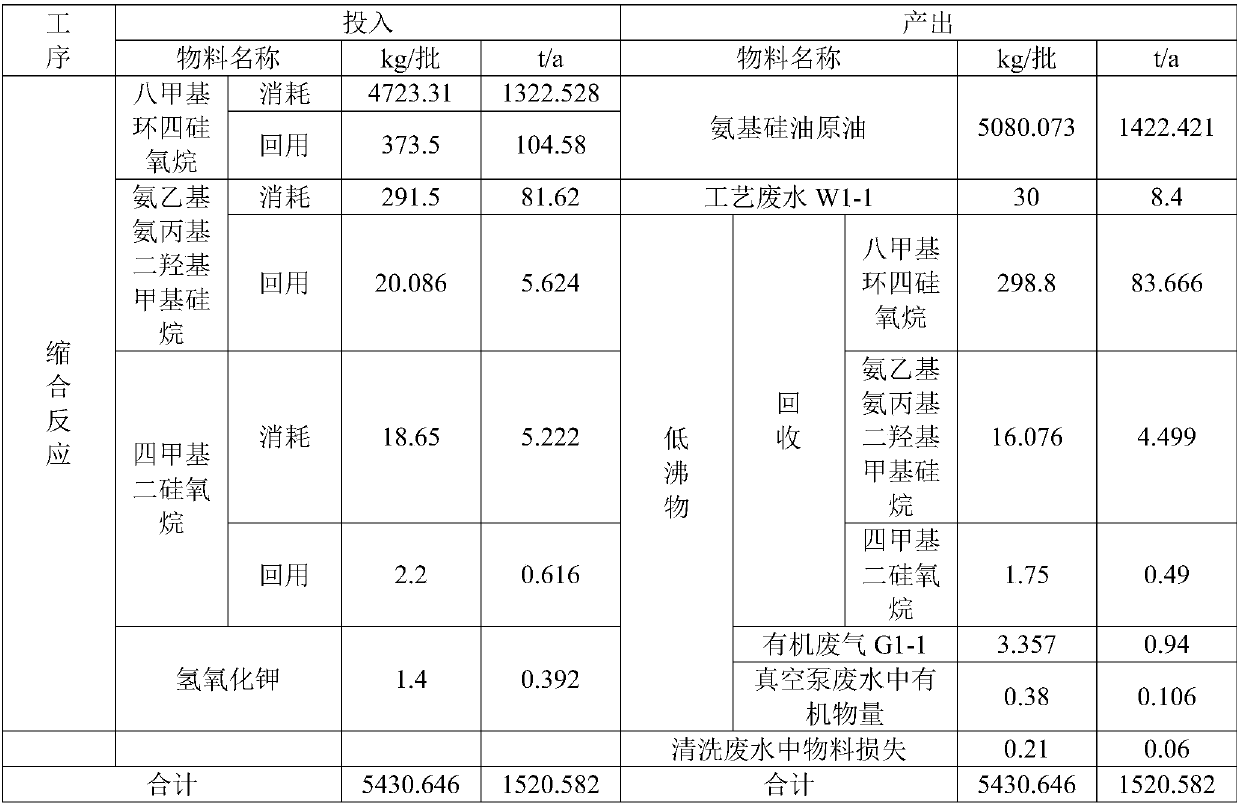

[0042] A kind of preparation technology of amino silicone oil crude oil, described preparation technology comprises following preparation steps:

[0043] 1) Raw material premixing: premix dimethylsiloxane mixed ring body and tetramethyldisiloxane at 100°C to obtain premix I, and aminoethylaminopropyldihydroxymethylsilane Premixed with potassium hydroxide at 70°C to obtain premix II, in which dimethylsiloxane mixed ring body, tetramethyldisiloxane, aminoethylaminopropyldihydroxymethylsilane and hydrogen The mass ratio of potassium oxide is 4500:15:270:1;

[0044] 2) Put the premix I and premix II obtained in step 1) in a container for condensation. During the condensation, the reaction temperature is controlled by hot steam to 100°C, and the condensation reaction product is obtained after 12 hours of reaction. During the reaction, the steam passes through the secondary condensing device to recycle;

[0045] 3) Distill the condensation reaction product obtained in step 2) unde...

Embodiment 2

[0047] A kind of preparation technology of amino silicone oil crude oil, described preparation technology comprises following preparation steps:

[0048] 1) Raw material premixing: Premix dimethylsiloxane mixed ring body and tetramethyldisiloxane at 120°C to obtain premix I. Aminoethylaminopropyldihydroxymethylsilane Premixed with potassium hydroxide at 90°C to obtain premix II, in which dimethylsiloxane mixed ring body, tetramethyldisiloxane, aminoethylaminopropyldihydroxymethylsilane and hydrogen The mass ratio of potassium oxide is 5500:25:360:1.8;

[0049] 2) Put the premix I and premix II obtained in step 1) in a container for condensation. During the condensation, the reaction temperature is controlled by hot steam to 200°C, and the condensation reaction product is obtained after 20 hours of reaction. During the reaction, the steam passes through the secondary condensing device to recycle;

[0050] 3) Distill the condensation reaction product obtained in step 2) under ...

Embodiment 3

[0052] A kind of preparation technology of amino silicone oil crude oil, described preparation technology comprises following preparation steps:

[0053] 1) Raw material premixing: premix dimethylsiloxane mixed ring body and tetramethyldisiloxane at 110°C to obtain premix I, and aminoethylaminopropyldihydroxymethylsilane Premixed with potassium hydroxide at 80°C to obtain premix II, in which dimethylsiloxane mixed ring body, tetramethyldisiloxane, aminoethylaminopropyldihydroxymethylsilane and hydrogen The mass ratio of potassium oxide is 4800:18:291:1.4;

[0054] 2) Put the premix I and premix II obtained in step 1) in a container for condensation. During the condensation, the reaction temperature is controlled by hot steam to 150°C, and the condensation reaction product is obtained after 16 hours of reaction. During the reaction, the steam passes through the secondary condensing device to recycle;

[0055] 3) Distill the condensation reaction product obtained in step 2) un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com