Preparation method of mesoporous silicon oxide thin film material

A technology of mesoporous silicon oxide and thin film materials, which is applied in the preparation of low dielectric constant mesoporous silicon oxide thin film materials, in the field of divisional applications, and achieves the effects of good dielectric stability, uniform size distribution and good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1 A kind of preparation method of mesoporous silicon oxide film material

[0026] The P123 tri-block copolymer and PDMS-PEO di-block copolymer were added to the polymerized silica sol to form an oligomeric silicate precursor solution, and the silica sol was prepared by adding TEOS, water, hydrochloric acid (HCl) and ethanol ( ETOH) prepared by reflux at 60-80 ℃ for 80-100 min, the molar ratio of reactants is 1 TEOS: 0.008 P123: 0.017 PDMS-PEO: 72 H 2 O: 0.004 HCl: 33 ETOH; the precursor was aged at room temperature for 4-6 h. During the spin-coating process, the precursor solution was spin-coated onto the silicon wafer at a speed of 2500 rpm, and the spin-coating time was 25 s. The coating obtained after spin coating is baked at 100°C for 4-6 hours in an air atmosphere, and at 350°C for 1-2 hours to remove the template agent and obtain a silicon oxide film material with a mesoporous structure.

[0027] The triblock copolymer P123 in this example ( M w = ...

Embodiment 2

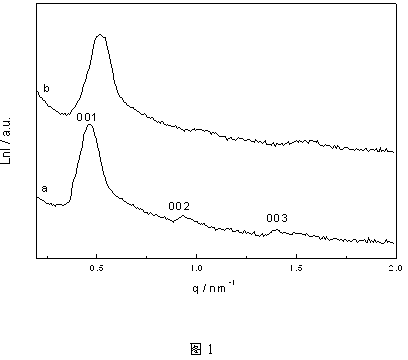

[0028] Example 2 Small-angle X-ray scattering (SAXS) measurement was carried out on the silicon oxide film material obtained in Example 1 by Nanostar U small-angle X-ray scattering instrument (CuKα) from Bruker, Germany. The tube pressure was 40 kV, the tube flow was 35 mA, and the recording time was 30 min. The resulting SAXS as figure 1 shown. Depend on figure 1 It can be seen that the SAXS spectra of As-made samples are at 0.46, 0.93 and 0.39 nm -1 3 clear diffraction peaks appear at , the three diffraction peaks q The value ratio is 1:2:3, which is assigned as the crystal plane diffraction peak of the layered mesoporous structure. After roasting under the protection of nitrogen at 350 °C, the clarity of the SAXS spectrum of the obtained sample decreased, and the diffraction peaks became wider, but two obvious diffraction peaks could also be observed, indicating that the layered structure after roasting at 350 °C still maintains the mesoporous structure. . The rel...

Embodiment 3

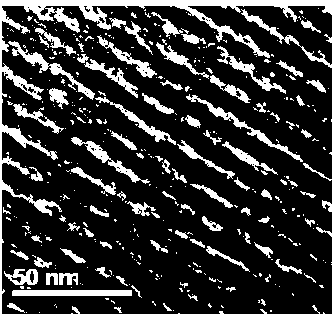

[0029] Example 3 The structure of the silicon oxide thin film material obtained in Example 1 was characterized by a Japanese JEOL JEM2011 high-resolution transmission electron microscope (TEM), and the accelerating voltage was 200 kV. The sample preparation process is as follows: the powdered silicon oxide thin film material obtained in Example 1 is dissolved in ethanol to form a slurry state, and the slurry is hanged on a copper net with a carbon film, and can be directly used for observation after drying. The TEM results of the resulting mesoporous silica coating are as follows figure 2 shown. Depend on figure 2 It can be seen that the layered structure remains after firing. It shows that the mesoporous silica thin layer with good skeleton stability can be successfully prepared by the co-template method. The average interlayer spacing is about 12.5 nm, which is comparable to figure 1 The SAXS spectrum characterization results are consistent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com