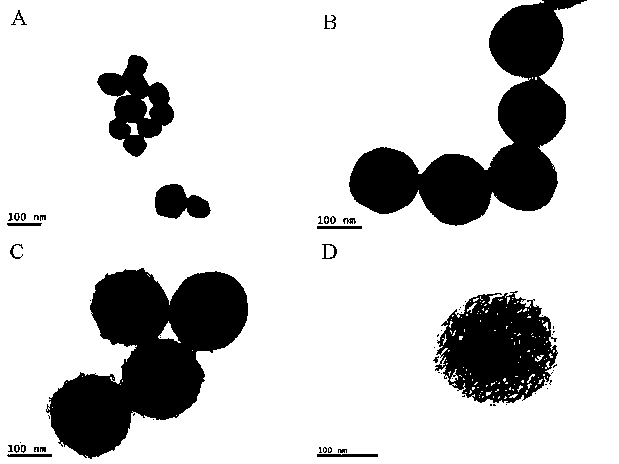

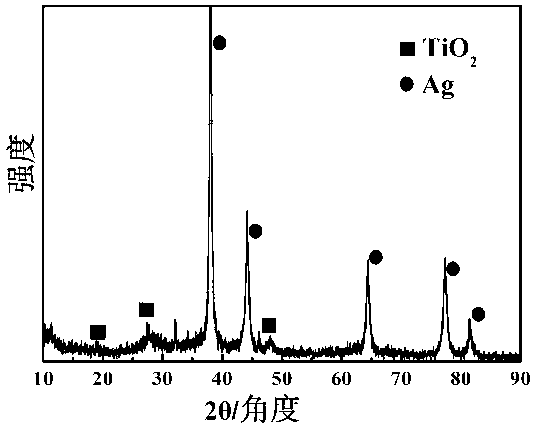

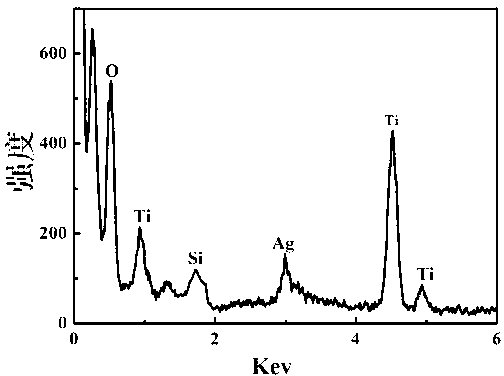

Preparation method of nest-like core-shell-structure Ag@mTiO2 nano composite material

A technology of nanocomposite materials and core-shell structure, which is applied in the field of preparation of AgmTiO2 nanocomposite materials, can solve problems such as preparation difficulties, and achieve the effect of unique structure, adjustable particle size and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] (1) According to known literature reports to synthesize Ag nanoparticles (as before), the typical process is as follows: 2.5 g of PVP was dissolved in 150 ml of ethylene glycol, 1 g of AgNO 3 Add it to the above solution, mix it evenly, add it into a three-necked flask, and react in an oil bath at 130 °C for 1 h, then use a certain amount of acetone as a precipitant to centrifuge to obtain Ag nanoparticles, and redisperse them In ethanol, a solution of Ag nanoparticles is obtained;

[0020] (2) Add 10 ml of the solution obtained in step (1) to the mixed solution of ethanol and water with a volume ratio of 4:1, then add 2.5 ml of ammonia water (28%), mix well, and then add 2000 μl dropwise TEOS, reacted for 12 h, after conventional centrifugation, washing, and drying, we obtained the intermediate product AgSiO 2 composite materials;

[0021] (3), 0.15 g AgSiO obtained in step (2) 2 Nanoparticles were redispersed in 150 ml of ethanol, and 0.9 ml of ammonia solution (28...

Embodiment 2

[0024] The implementation process is the same as in Example 1 except for the following differences.

[0025] 0.15 g AgSiO obtained in the above step (2) 2 Nanoparticles were redispersed in 150 ml of ethanol, and 0.9 ml of ammonia solution (28 %) was added, sonicated for 15 min, and then 500 μl of TBOT was slowly added dropwise, and then the temperature was 45 °C for 24 h under magnetic stirring. After conventional centrifugation, washing and drying, the product AgSiO 2 TiO 2 Composite materials, finally through the above step (4) to get bird's nest-like AgTiO 2 nanocomposites.

[0026] The obtained results are basically similar to those of Example 1, except that after the final particles are etched, the outer shell is cracked to a certain extent, which shows that TiO 2 The shell needs to have a certain thickness in order to get a more ideal result.

Embodiment 3

[0028] The implementation process is the same as in Example 1 except for the following differences.

[0029] 0.5 g AgSiO obtained in the above step (3) 2 TiO 2 The composite material was dispersed in 0.24 M ammonia solution, after mixing evenly, it was put into an autoclave, and after reacting in an oven at 150 °C for 24 h, the obtained product was washed repeatedly with 0.1 M hydrochloric acid solution and deionized water Until the pH value is close to neutral, after drying, the final product AgmTiO 2 nanocomposites.

[0030] The obtained result is different from that of Example 1, in that a sandwich hollow structure is produced, the Ag core can move freely in the inner cavity, and the obtained shell is only fluffy and expanded instead of a flaky bird's nest-like shell.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com