Cutting insert, cutting tool, and method for producing cut product using said cutting insert and cutting tool

一种切削镶刀、切削刃的技术,应用在切削刀片、工具夹、制造工具等方向,能够解决切屑排出方向左右偏离、切屑排出性变劣等问题,达到排出方向稳定、提高排出性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

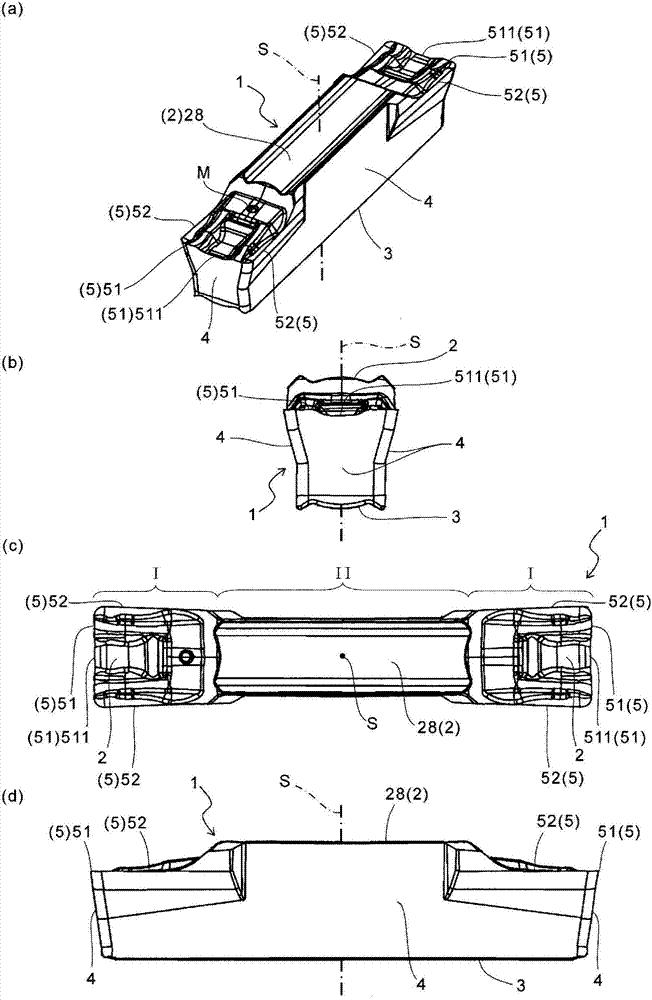

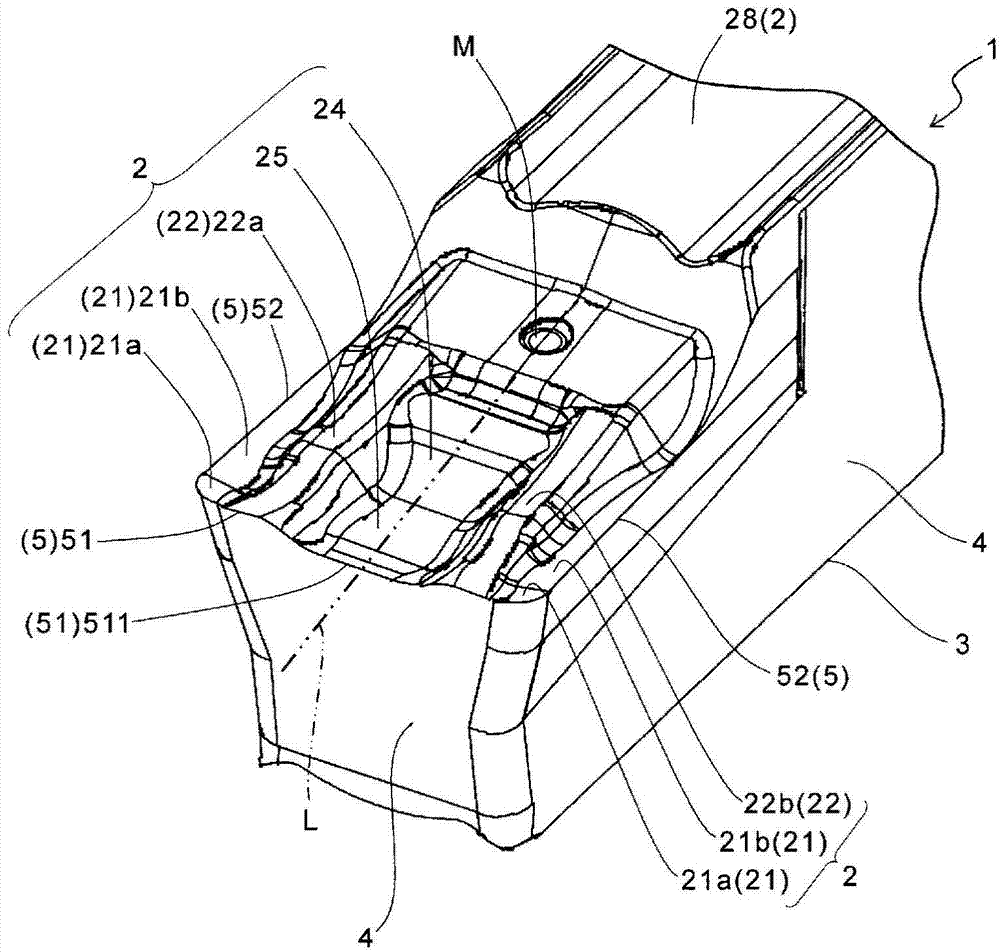

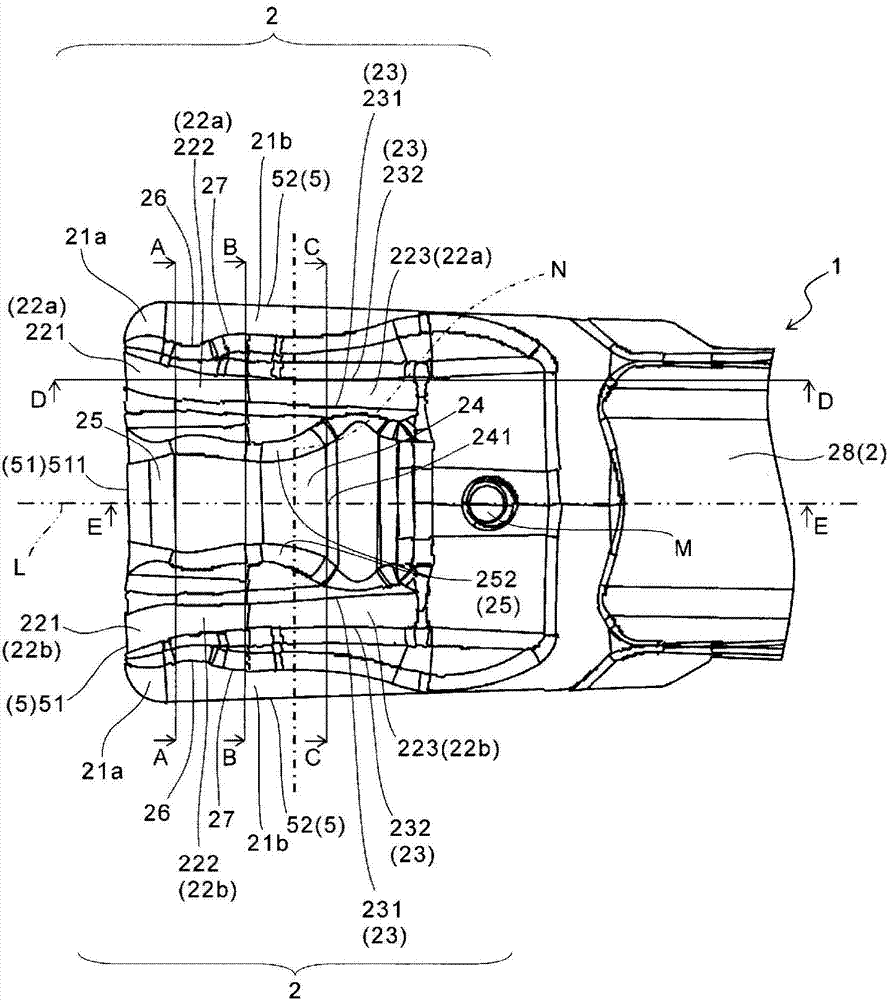

[0026] Below, refer to Figure 1 to Figure 7 A first embodiment of the cutting insert of the present invention will be described in detail.

[0027] Such as figure 1 As shown, the insert 1 of this embodiment has a prismatic shape and has: cutting parts I, I, which are located at both ends; and a clamping part II, which is located between the cutting parts I, I and has The toolholder 11 is the clamping surface 28 that is in contact with the toolholder 11, that is, the cutting part I is provided with a pair of two ends of the clamping part II. In this embodiment, if figure 1 As shown, in order to identify the cut portion I, a mark M is attached to one of the pair of cut portions I, I.

[0028] Examples of the material of the cutting insert 1 include cemented carbide, cermet, and the like. Examples of the composition of the cemented carbide include WC-Co obtained by adding cobalt (Co) powder to tungsten carbide (WC) and sintering, and WC-TiC-Co obtained by adding titanium car...

no. 2 approach

[0057] Second, refer to Figure 8 ~ Figure 11 The insert according to the second embodiment of the present invention will be described in detail. It should be noted that, in Figure 8 ~ Figure 11 , against the above Figure 1 to Figure 7 The same structural parts are denoted by the same symbols and descriptions thereof are omitted.

[0058] In plan view, it is preferred that the end 241' on the side away from the first cutting edge 51' in the central inclined portion 24', in other words, the end portion 241' on the higher side of the central inclined portion 24' and the second inclined The high end 223'u of the surface 223' is located on the same straight line, or is located behind the high end 223'u of the second inclined surface 223'.

[0059] In this embodiment, if Figure 9 As shown, the high end 241' of the central slope 24' and the high end 223'u of the second slope 223' are located on the same straight line. That is, if the straight line N' passing through the cent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com