Non-refrigerating film infrared focal plane array detector structure and production method thereof

An infrared focal plane, array detector technology, applied in electrical radiation detectors, semiconductor devices, final product manufacturing, etc. The effect of thermal response characteristics, high filling rate, and good thermal isolation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

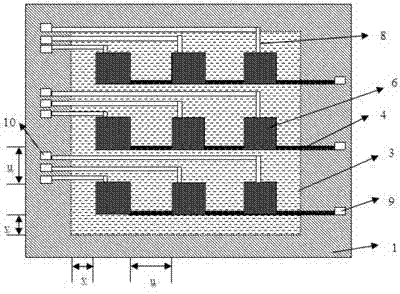

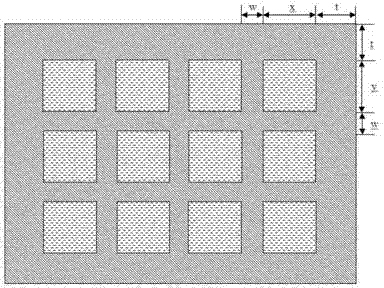

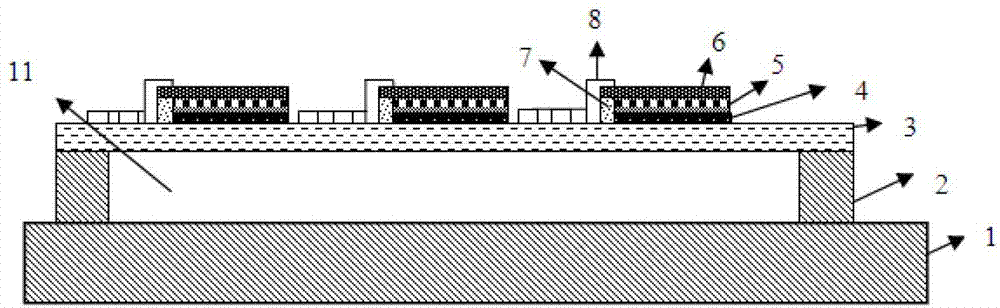

[0046] In this embodiment, the uncooled thin-film infrared focal plane array detector structure includes a first substrate 1 containing a readout circuit, a second substrate 2 containing a heat-isolated microbridge array and a sensitive element array, and the first substrate The sheet 1 and the second substrate 2 are bonded together by silicon-silicon bonding technology, and each thermally isolated microbridge unit in the thermally isolated microbridge array uses the etched second substrate 2 as a bridge pier to communicate with the The supporting layer 3 tightly bonded to the top surface of the bridge pier is the bridge deck, and the thickness of the air gap 11 of each heat-isolated micro-bridge unit is the same as the thickness of the second substrate, as figure 1 , figure 2 As shown; the first substrate 1 is a silicon substrate, the second substrate 2 is a double-polished silicon substrate, and the bridge deck (support layer 3) is SiO 2 Floor. The thermally isolated micr...

Embodiment 2

[0048] In this embodiment, the uncooled thin-film infrared focal plane array detector structure includes a first substrate 1 containing a readout circuit, a second substrate 2 containing a heat-isolated microbridge array and a sensitive element array, and the first substrate The sheet 1 and the second substrate 2 are bonded together by silicon-silicon bonding technology, and each thermally isolated microbridge unit in the thermally isolated microbridge array uses the etched second substrate 2 as a bridge pier to communicate with the The supporting layer 3 tightly bonded to the top surface of the pier is the bridge deck, and the thickness of the air gap 11 of each heat-isolated micro-bridge unit is the same as that of the second substrate; the first substrate 1 is a silicon substrate, and the second substrate 2 is Double polished silicon substrate, bridge deck (support layer 3) is SiO 2 / Si 3 N 4 composite layer. The thermally isolated microbridge array is composed of 8×8 id...

Embodiment 3

[0050] This embodiment is a method for preparing the uncooled thin-film infrared focal plane array detector structure described in Embodiment 1, and the steps are as follows:

[0051] (1) Preparation of the bonding surface pattern of the first substrate

[0052] A silicon wafer is used as the first substrate 1, and a titanium film with a thickness of 30 nm is deposited on the surface of the first substrate 1 containing the readout circuit, and a gold film with a thickness of 120 nm is deposited on the surface of the titanium film, and then according to the design Photolithographic graphics of the electrode and bonding surface pattern to realize the patterning of the bonding surface;

[0053] (2) Preparation of support layer

[0054] A double-polished silicon wafer is used as the second substrate 2, and both sides of the second substrate are thermally oxidized to form a layer of 600nm thick and dense SiO on both sides. 2 layer; select one side as the support layer 3, which is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com