Control device of lifting mechanism of industrial vehicle and control method

A technology for industrial vehicles and lifting mechanisms, used in lifting devices, fluid pressure actuation devices, mechanical equipment, etc., can solve the problem of affecting the performance and service life of motors and hydraulic pumps, and is not suitable for large-scale promotion and application. problems such as low efficiency, to achieve the effect of improving stability and safety, reducing impact and energy consumption, and reducing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The following descriptions are only preferred embodiments of the present invention, and do not limit the scope of the present invention.

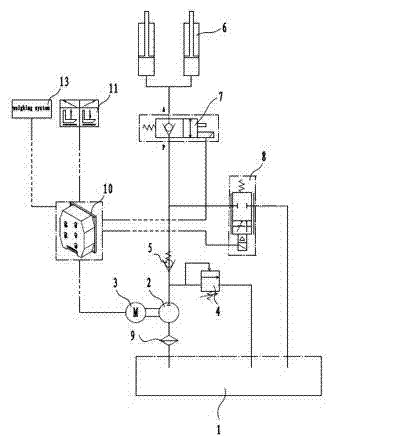

[0043] Examples, see attached figure 1 A control device for an industrial vehicle lifting mechanism, including a fuel tank 1, a quantitative hydraulic pump 2, a motor 3 that drives the quantitative hydraulic pump 2 to rotate, an overflow valve 4 connected to the outlet of the quantitative hydraulic pump 2, and a one-way valve 5 , a hydraulic cylinder 6, an electromagnetic reversing valve 7 arranged between the one-way valve 5 and the hydraulic cylinder 6, and an electromagnetic proportional valve connected to the outlet of the hydraulic pump 2 and connected in parallel with the electromagnetic reversing valve 7 8. A programmable controller 10 for controlling the opening and closing of the motor 3, controlling the opening and closing of the electromagnetic reversing valve 7, and controlling the opening of the electromagnetic proportiona...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com