Inner bayonet type circular connector

A circular connector, bayonet-type technology, applied in the direction of connection, two-part connection device, parts of the connection device, etc., can solve the problems of poor connection, short service life, unreliable operation of the connector, etc., and achieve stable operation. The effect of high resistance, good waterproof performance, excellent sealing and compression resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

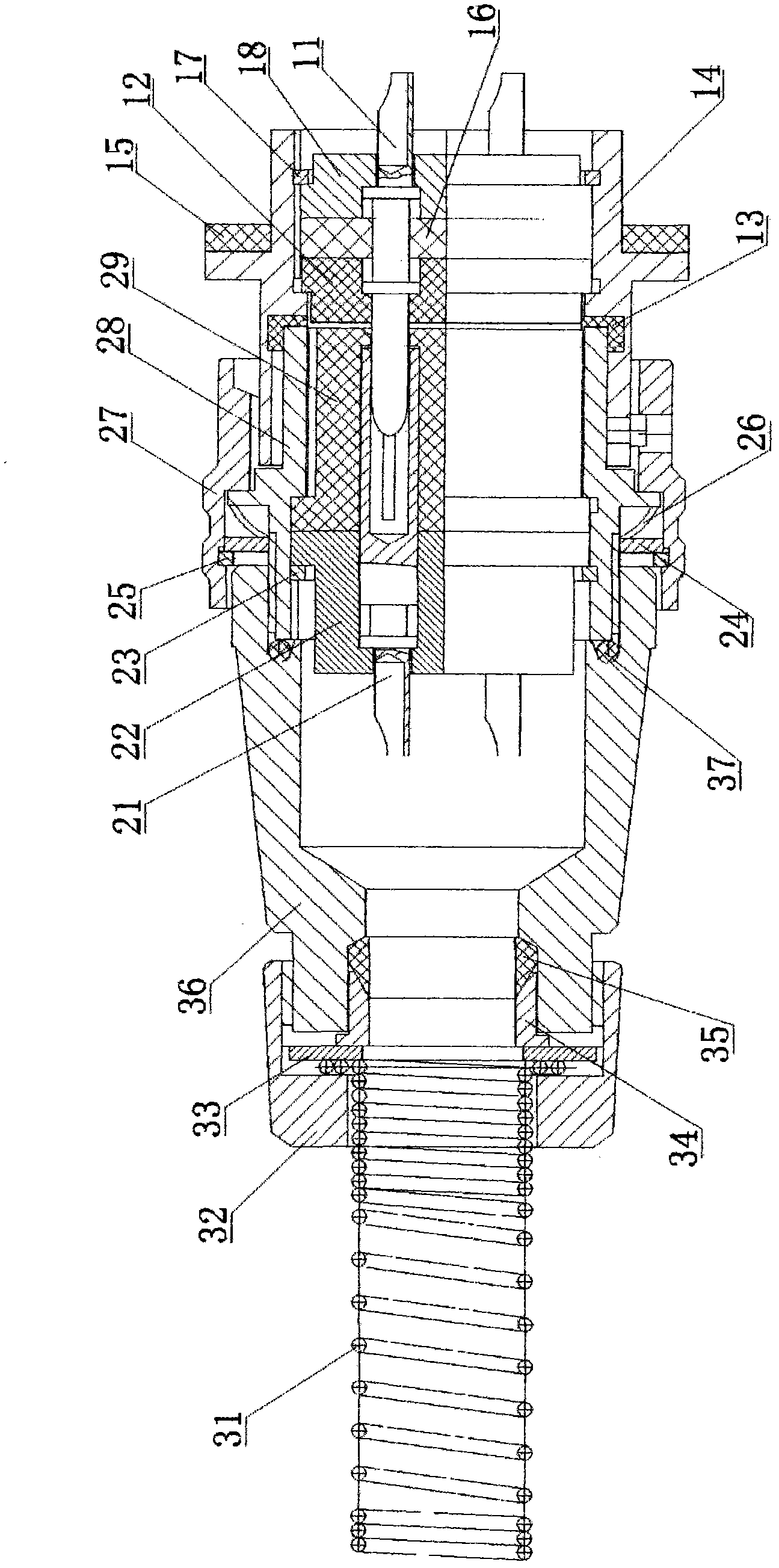

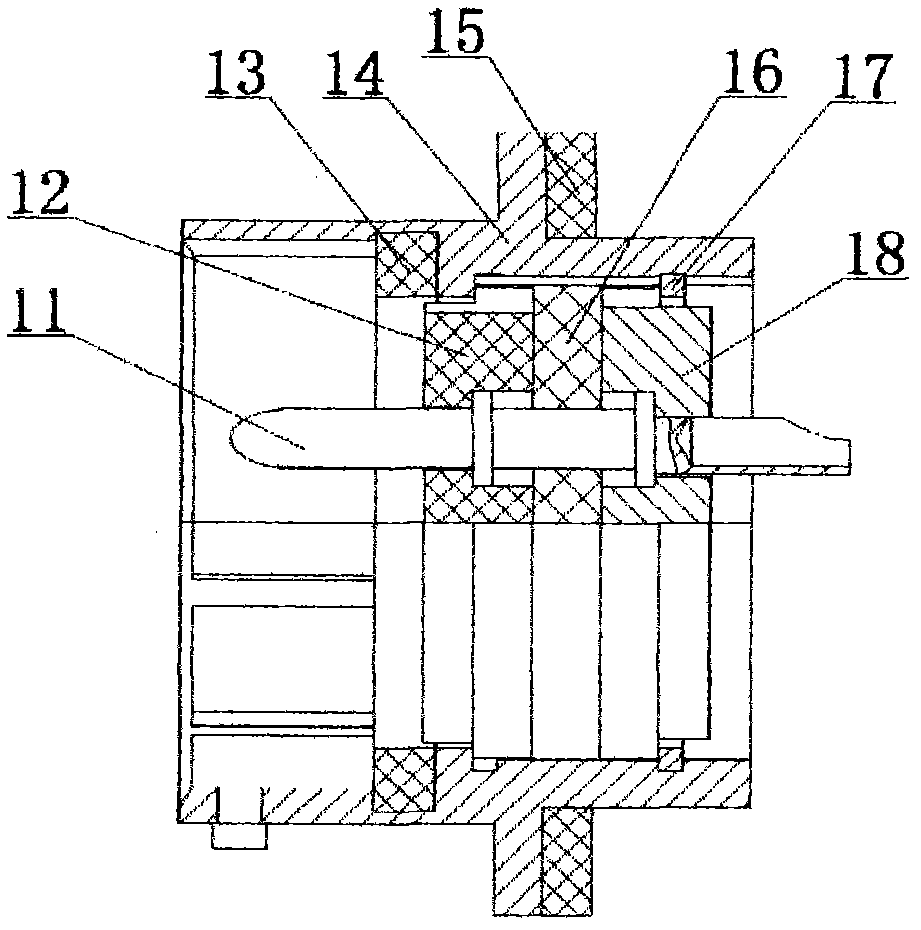

[0024] A bayonet type circular connector such as figure 1 As shown, it includes a socket, a plug and a tail attachment, and the plug is respectively connected to the socket and the tail attachment by thread locking. The shells of sockets, plugs and tail accessories are made of various materials such as aluminum alloy and copper alloy, which are suitable for various harsh environments.

[0025] Such as figure 1 , figure 2 As shown, the socket includes a square disc convex body 14 for connecting electrical equipment, several pin insulators 12 arranged in the square disc convex body 14 and pins 11 arranged in the pin insulator 12, and the surface of the pins gilded. The front part of the pin 11 is provided with a pin cover 18, and a waterproof pad 16 is provided between the pin insulator 12 and the pin cover 18; the square disc convex body 14, the pin insulator 12, the pin 11 and the pin cover The board 18 is integrated by assembling glue.

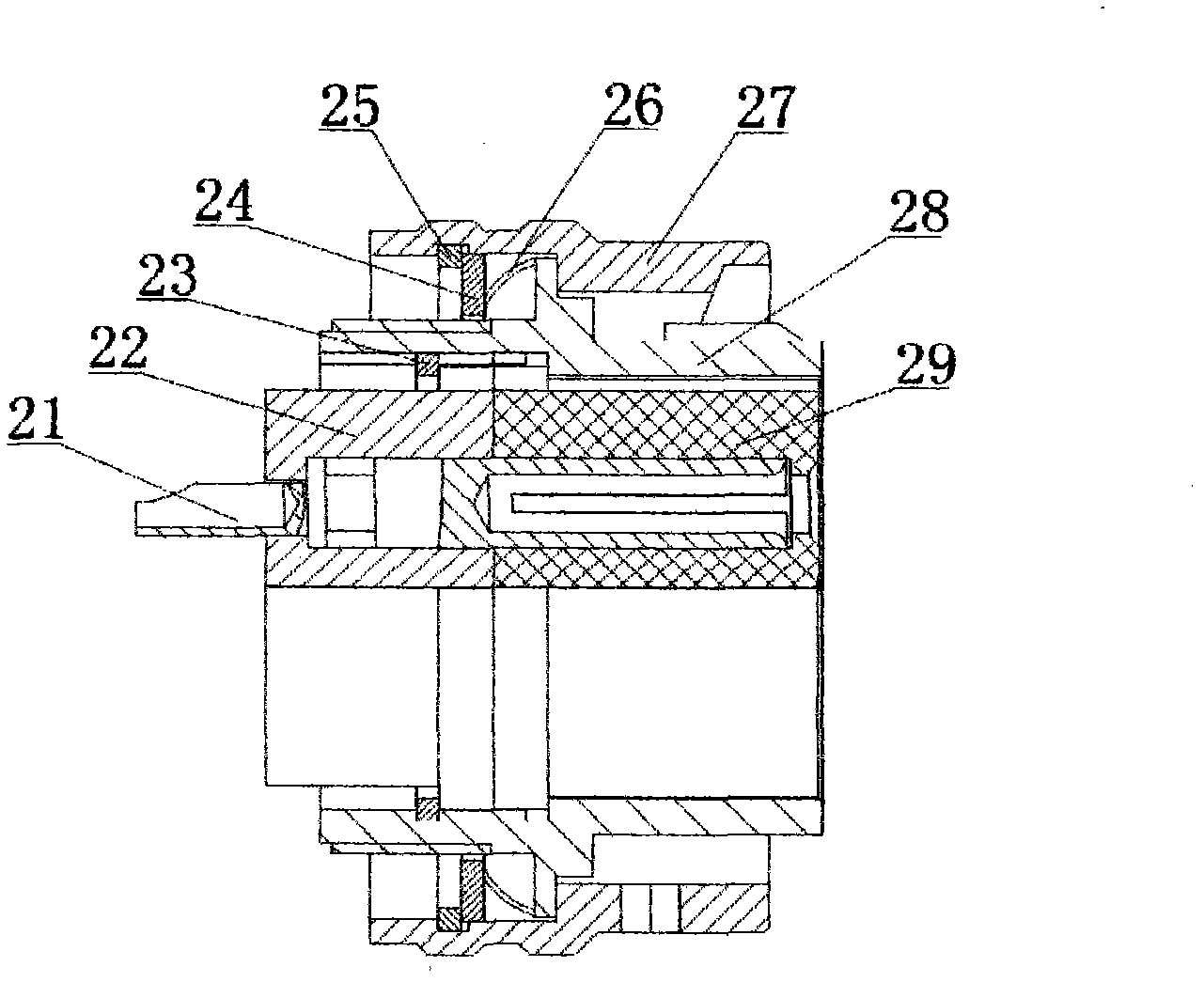

[0026] Such as figure 1 , ima...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com