Transformer paper oil insulation experiment device integrated with electric heating combination ageing and partial discharge

A transformer oil, partial discharge technology, applied in the direction of testing dielectric strength, testing ship construction, etc., can solve problems such as large difference in results, no obvious correlation between aging states, and no longer practical, and achieve good air tightness, Good test effect, convenient operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

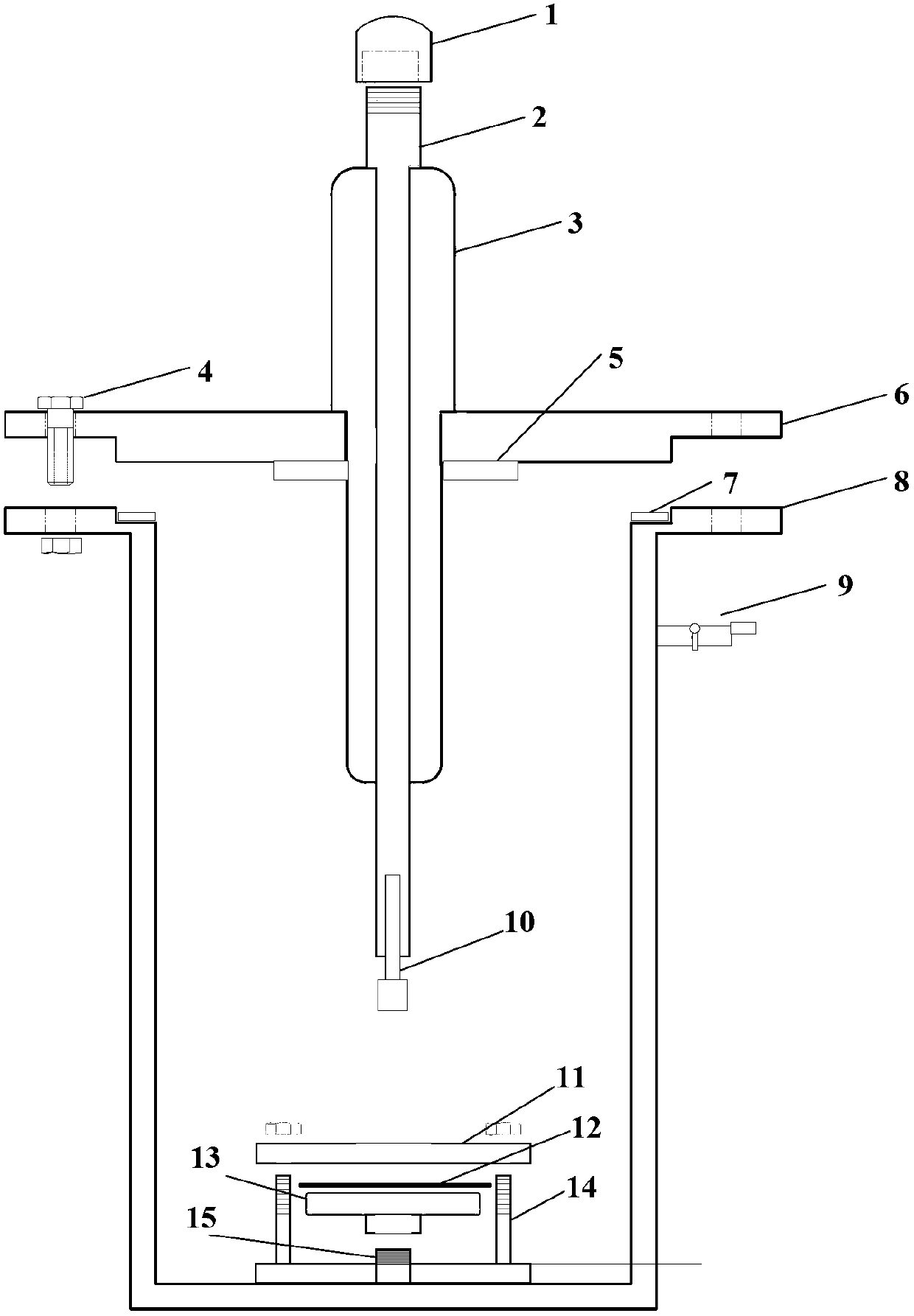

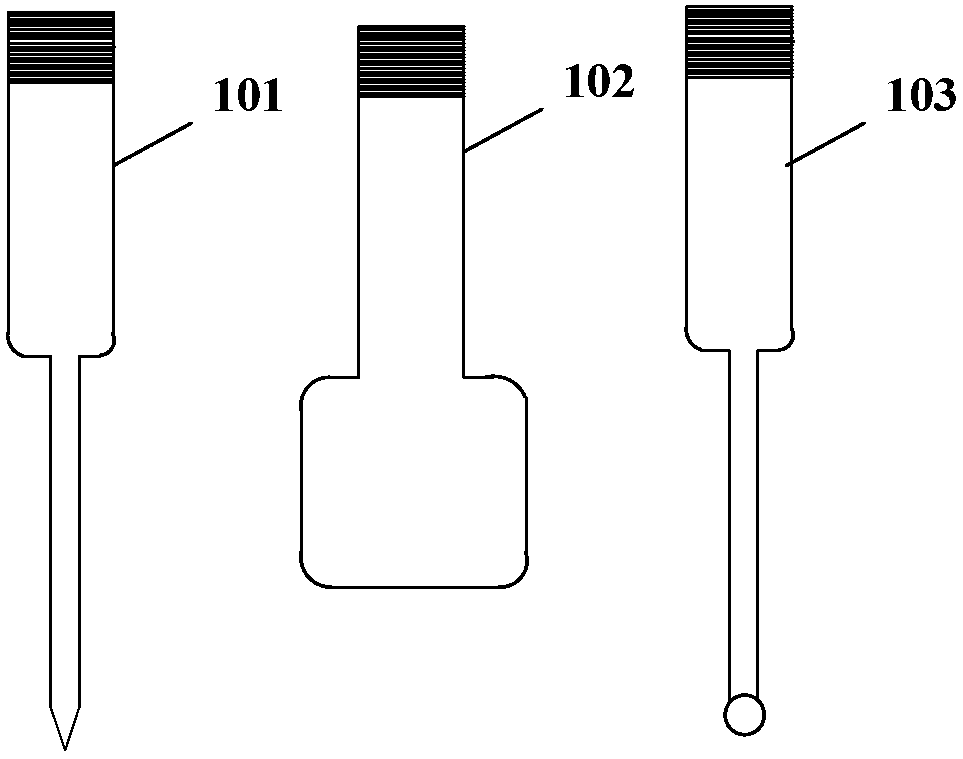

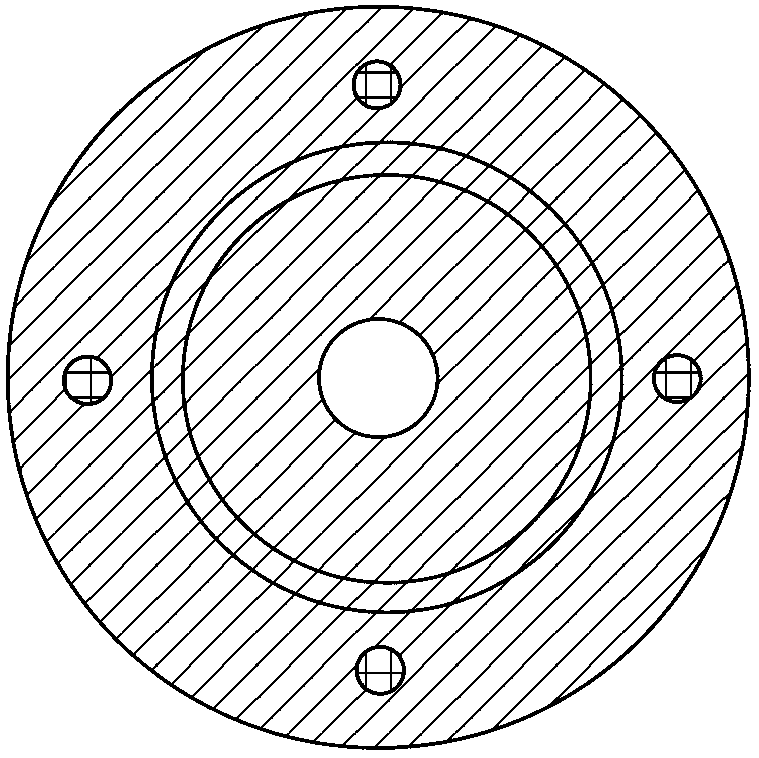

[0050] figure 1It is a transformer oil-paper insulation electric heating combined aging test device; figure 2 It is a high-voltage needle electrode / column electrode / ball electrode; image 3 It is the sealing cover and its waterline groove; Figure 4 Wiring for the partial discharge test platform; Figure 5 It is a corona discharge defect model electrothermal combined aging device; Figure 6 It is the PRPD spectrum of 24kV corona discharge under combined electrothermal aging; Figure 7 It is an electrothermal combined aging device for surface discharge defect model; Figure 8 It is the PRPD spectrum of 23kV surface discharge under combined electrothermal aging; Figure 9 It is an electrothermal combined aging device for the air gap discharge defect model; Figure 10 It is the PRPD spectrum of 7kV air-gap discharge under combined electrothermal aging, as shown in the figure: a transformer oil-paper insulation electrothermal combined aging and partial discharge integrated ...

Embodiment 2

[0072] The difference between this embodiment and embodiment 1 is only:

[0073] see figure 1 , The transformer oil-paper insulation defect model of the preferred embodiment is an electrothermal combined aging test and partial discharge integrated test device, referred to as an aging tank, which includes a high-voltage part, a low-voltage part and a sealed tank part.

[0074] The high-voltage part includes a high-voltage corona cover 1 made of copper, a high-voltage copper electrode rod 2, a high-voltage conduit 3 made of polytetrafluoroethylene, a gasket 8 made of polytetrafluoroethylene, and a high-voltage needle made of copper. Electrode / column electrode / ball electrode 10;

[0075] The sealed tank part includes a sealed tank body 8 made of stainless steel, a sealed cover 6 made of stainless steel, a sealing gasket 7 made of polytetrafluoroethylene, a vent valve 9 made of stainless steel, and a fastening screw 4 made of stainless steel The conduit fastening screw 5 made of...

Embodiment 3

[0094]The difference between this embodiment and embodiment 2 only lies in:

[0095] Using the invention, a corona discharge defect model electrothermal combined aging and partial discharge test is carried out. Select 25# ordinary transformer oil and 1mm thick ordinary insulating cardboard as test materials, and cut the cardboard according to the diameter of 80mm. Pretreat the oil and paper according to the aforementioned method, place the cardboard on the low-voltage plate electrode 13, and adjust the distance between the needle electrode and the cardboard to 1mm, as Figure 5 shown. Cover the sealing cover 6, tighten the fastening screw 4, use the vent valve 9 to evacuate the device to 50Pa, feed nitrogen, then put the whole device into a constant temperature oil tank for oil bath, set the oil bath temperature to 90 degrees. The initial discharge voltage of corona discharge is 12kV, then keep it at 18kV for 10min, collect 2000 power frequency cycles after the discharge is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com