Method for testing cracking toughness of materials by orthogonal cutting process

A fracture toughness and cutting force technology, applied in the fields of machining and material property testing, can solve the problems of complex preparation process, long measurement process, passivation of cracks in the plastic deformation area, etc., to achieve simple preparation and simple testing process. row, repeatable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

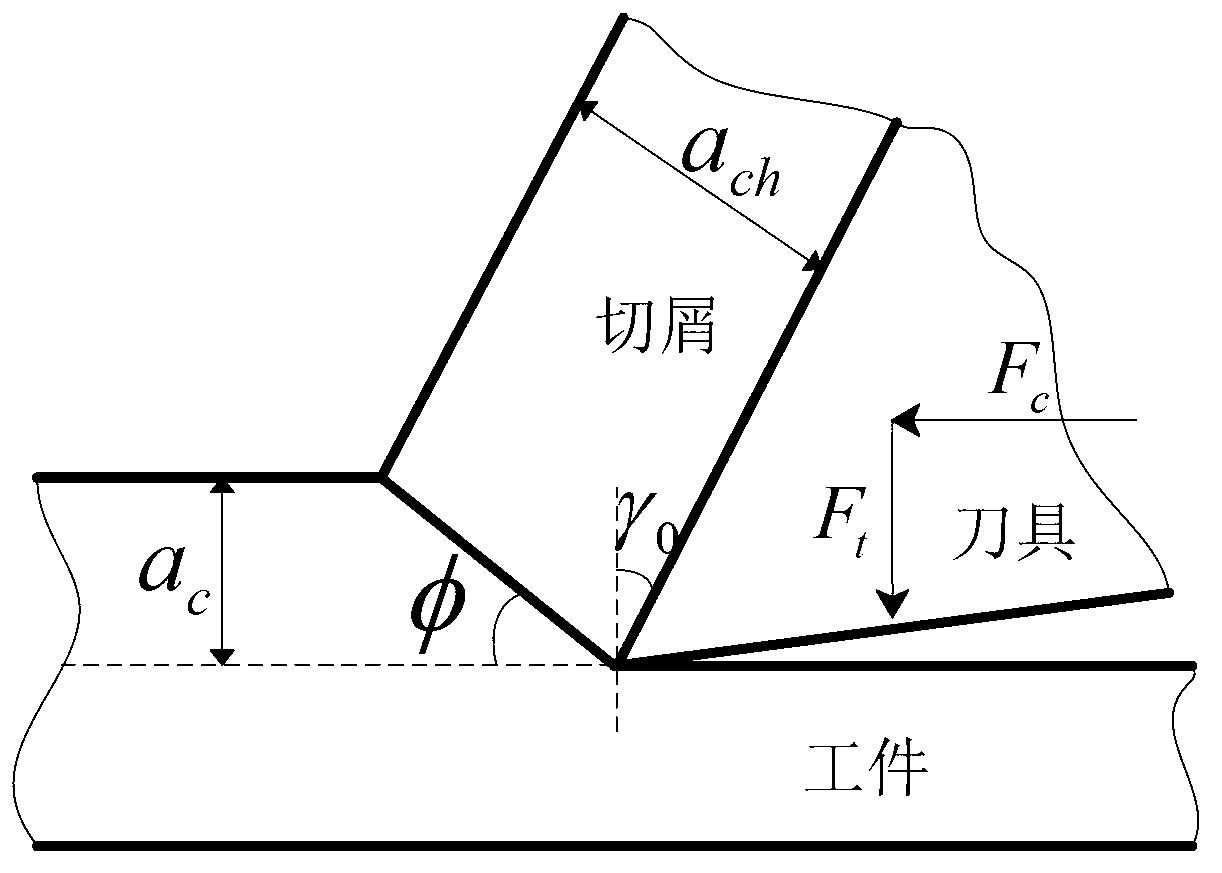

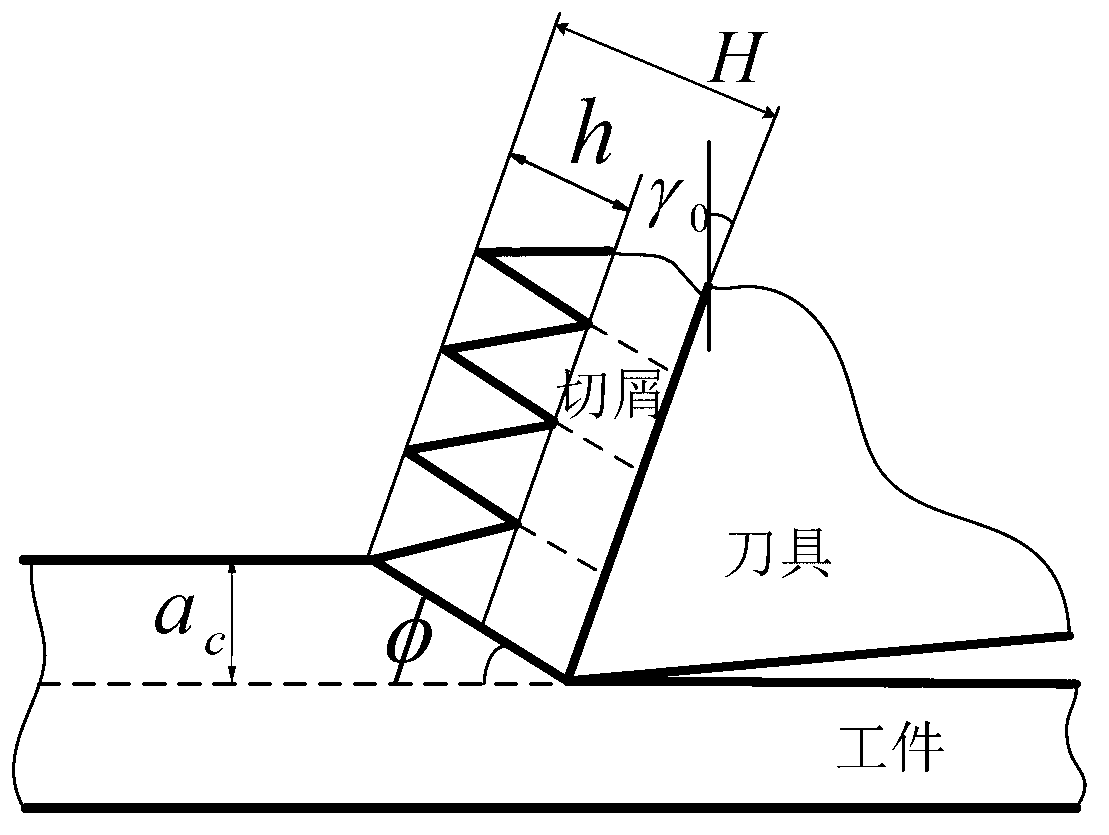

Method used

Image

Examples

Embodiment

[0061] Table 1: Cutting experimental data (Kobayashi) and calculation results of polymers PE and PC

[0062]

[0063] According to the above method, combined with the experimental data of cutting experiments of two polymers PE and PC in the literature "Machining of plastics" (McGraw-Hill, New York, 1967) by Akira Kobayash, as shown in Table 1, a F c / a w -(F t / a w )tanφ to (a c / 2) (tanφ+1 / tanφ) straight line, from the slope and intercept of the straight line can be determined respectively σ s and G c value (such as Figure 5 ), Figure 5 In the regression line equation, x and y represent abscissa and ordinate respectively, and R 2 Indicates the linear correlation coefficient, from which the yield strength σ of the two polymers PE and PC is obtained s and the fracture toughness value G c See Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com