Method for preparing CeO2 nanometer solid sphere by using CTAB (Cetyltrimethyl Ammonium Bromide) as soft template

A technology of solid spheres and soft templates, applied in the direction of nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problem of high energy consumption, and achieve the effect of cheap raw materials, low cost, and simple process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Step 1: Analytical pure Ce(NO 3 ) 3 ·6H 2 O was dissolved in deionized water to obtain Ce(NO 3 ) 3 solution;

[0015] KBrO 3 , CTAB (cetyltrimethylammonium bromide) and Ce(NO 3 ) 3 ·6H 2 O mixed KBrO with a molar ratio of 3:2:1 3 , CTAB joined Ce(NO 3 ) 3 The solution was continuously stirred at 60°C for 2 hours to obtain a mixed solution;

[0016] Step 2: Move the mixed solution into the reaction kettle, place it in an oven at 180°C for 15 hours, centrifuge and wash after the reaction, and dry at 80°C to obtain solid spherical CeO 2 Nano powder.

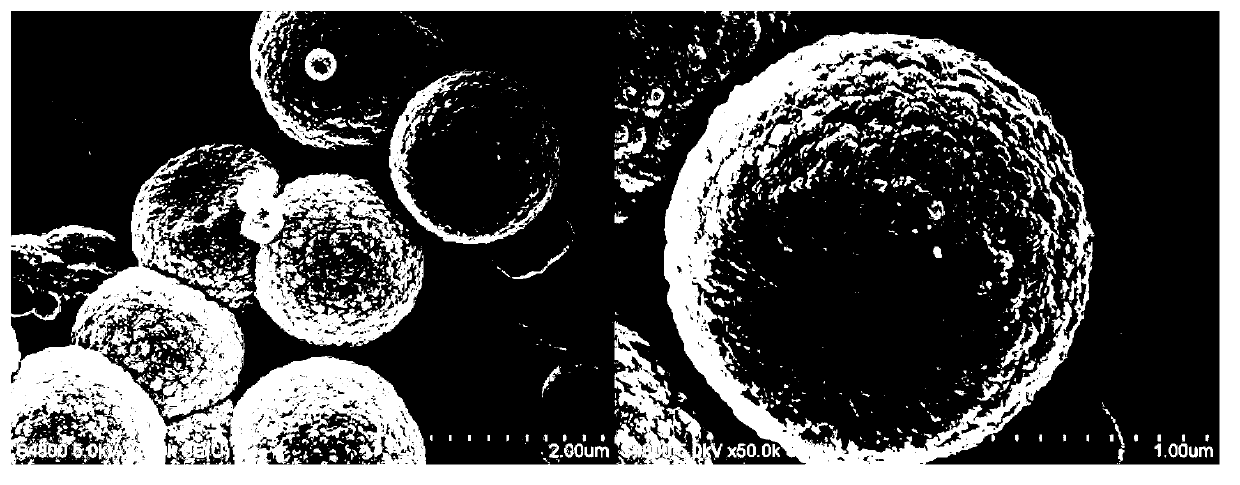

[0017] The resulting solid spherical CeO 2 The nano-powder is measured with a D / Max-2200pc type X-ray diffractometer produced by Japan Rigaku Company, and the results are as follows: figure 1 As shown, the pure phase CeO with better crystallinity was obtained 2 Nano solid spheres, the JCPDS card number of the found product is 33-0394, which belongs to the cubic crystal system. The microscopic morphology of the...

Embodiment 2

[0019] Step 1: Analytical pure Ce(NO 3 ) 3 ·6H 2 O was dissolved in deionized water to obtain Ce(NO 3 ) 3 solution; the KBrO 3 , CTAB (cetyltrimethylammonium bromide) and Ce(NO 3 ) 3 ·6H 2 O mixed KBrO with a molar ratio of 4:1.5:1 3 , CTAB joined Ce(NO 3 ) 3 The solution was continuously stirred at 60°C for 2 hours to obtain a mixed solution;

[0020] Step 2: Move the mixed solution into the reaction kettle, place it in an oven at 160°C for 20 hours, centrifuge and wash after reaction, and dry at 80°C to obtain solid spherical CeO 2 Nano powder.

Embodiment 3

[0022] Step 1: Analytical pure Ce(NO 3 ) 3 ·6H 2 O was dissolved in deionized water to obtain Ce(NO 3 ) 3 solution; the KBrO 3 , CTAB (cetyltrimethylammonium bromide) and Ce(NO 3 ) 3 ·6H 2 O mixed KBrO with a molar ratio of 6:0.5:1 3 , CTAB joined Ce(NO 3 ) 3 The solution was continuously stirred at 60°C for 2 hours to obtain a mixed solution;

[0023] Step 2: Move the mixed solution into the reaction kettle, place it in an oven at 190°C for 10 hours, centrifuge and wash after the reaction, and dry at 80°C to obtain solid spherical CeO 2 Nano powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com