Intermittent operation method and device for recovery and purification of hexachlorodisilane from chlorosilane residual liquid

A technology of chlorosilane raffinate and hexachlorodisilane, which is applied in the direction of halosilane and silicon halide compounds, can solve the problems of waste, not involving the recovery of hexachlorodisilane, and many impurities, and achieve the effect of increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

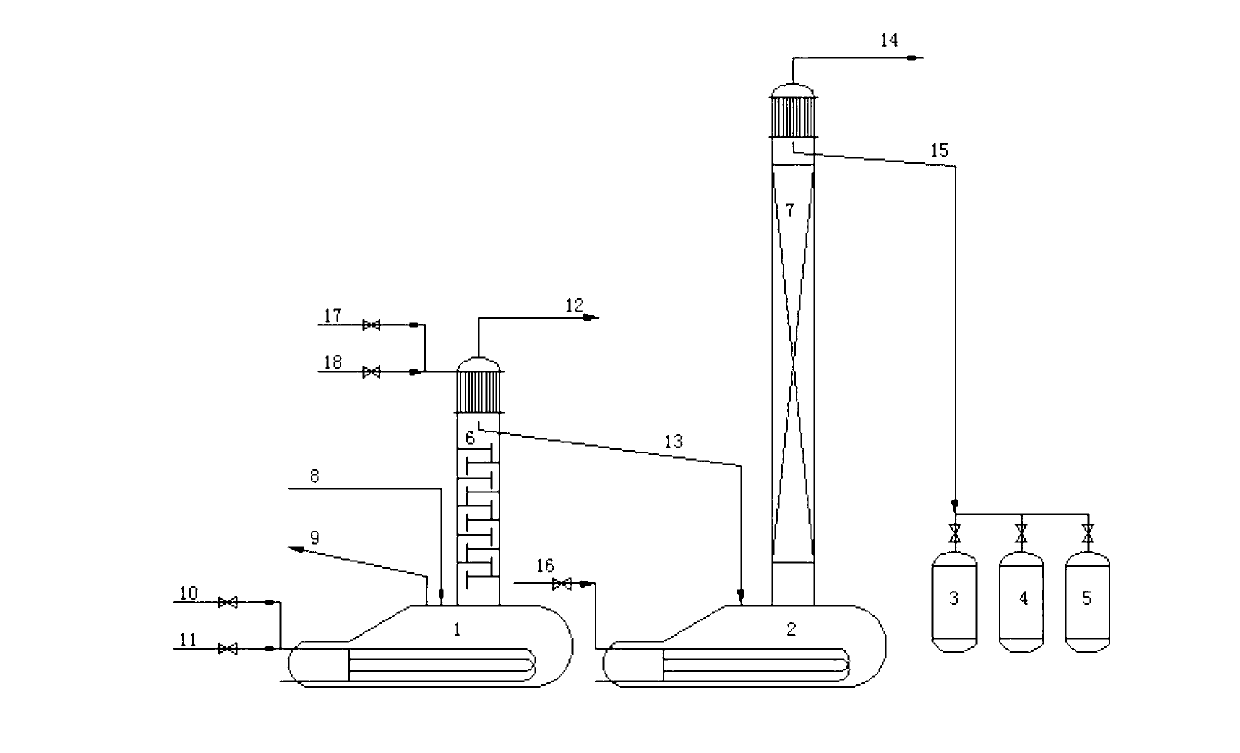

[0027] Combine below figure 1 Further details on the intermittent regimen

[0028] The technical scheme 1 of intermittent chlorosilane raffinate recovery treatment of the present invention is as follows:

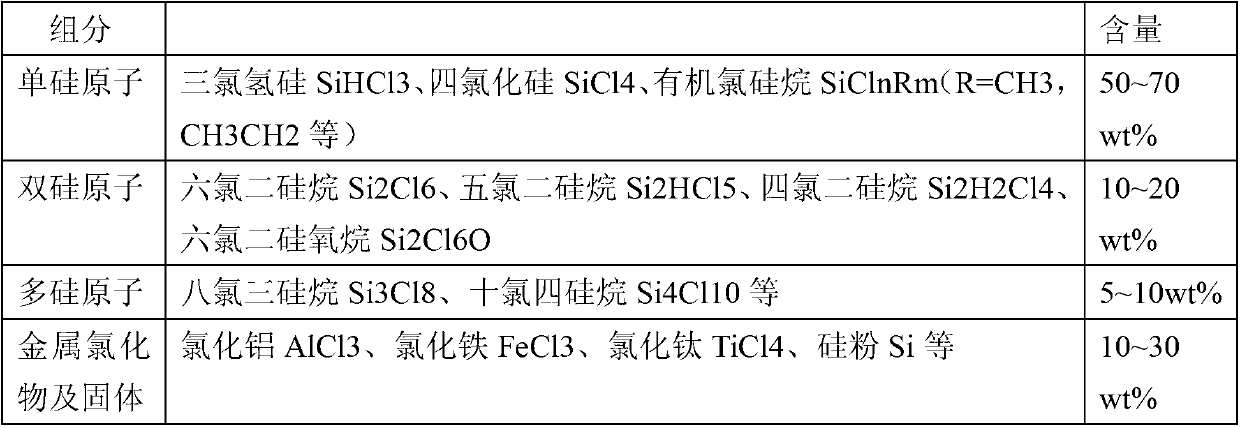

[0029] A batch-type chlorosilane residue recovery treatment device: including a primary fractionation tower (6), a pot-type reboiler for the primary fractionation tower (1), a batch rectification tower (7), a pot-type batch distillation tower Reboiler (2), chlorosilane storage tank (3), organosilane storage tank (4), hexachlorodisilane storage tank (5); it is characterized in that the bottom of the primary fractionation distillation column (6) is provided with a primary fractionation The kettle-type reboiler of the rectifying column (1), the feed inlet of the chlorosilane raffinate (8) is arranged on the upper part of the kettle-type reboiler of the primary fractionating column (1), and the kettle-type reboiler of the primary fractionating column The upper part of the devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com