Tobacco leaf bulk curing barn smoke waste heat utilization device

A technology for intensive roasting and waste heat from flue gas, applied in the field of energy saving and emission reduction, can solve the problems of high roasting cost, more flue gas emissions, lowering the total thermal efficiency of the roasting room, etc., to increase economic benefits, good environmental performance, reduce The effect of consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

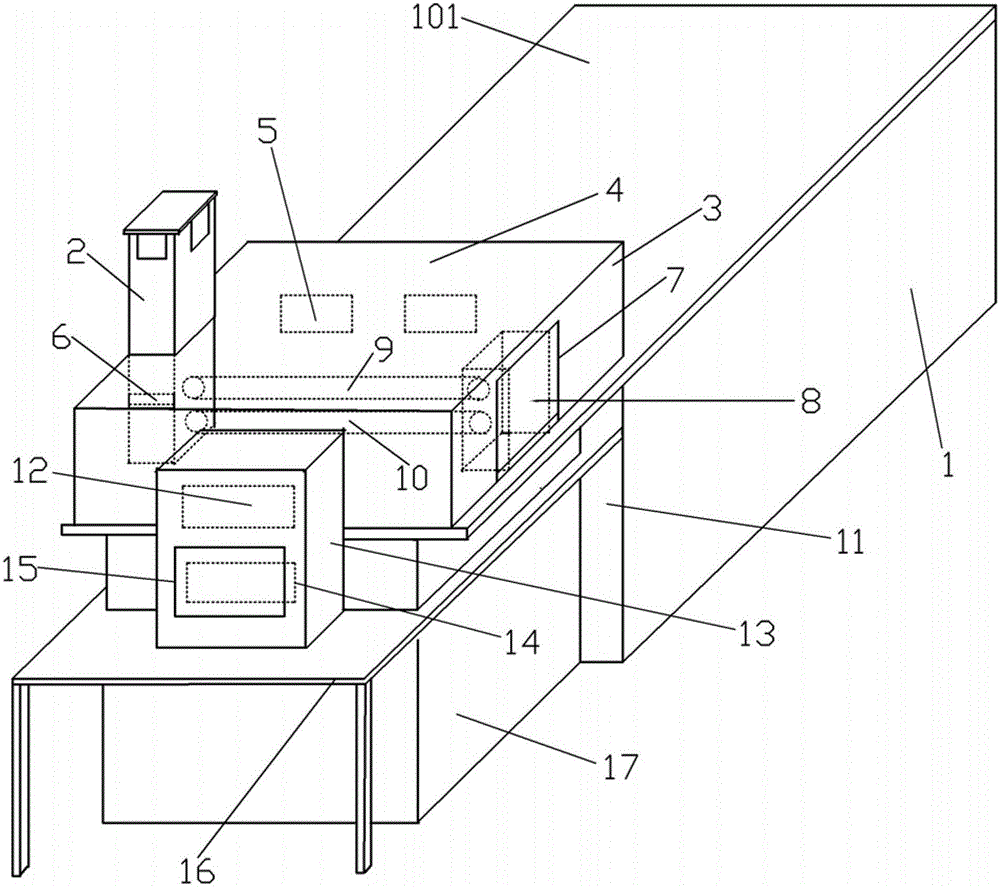

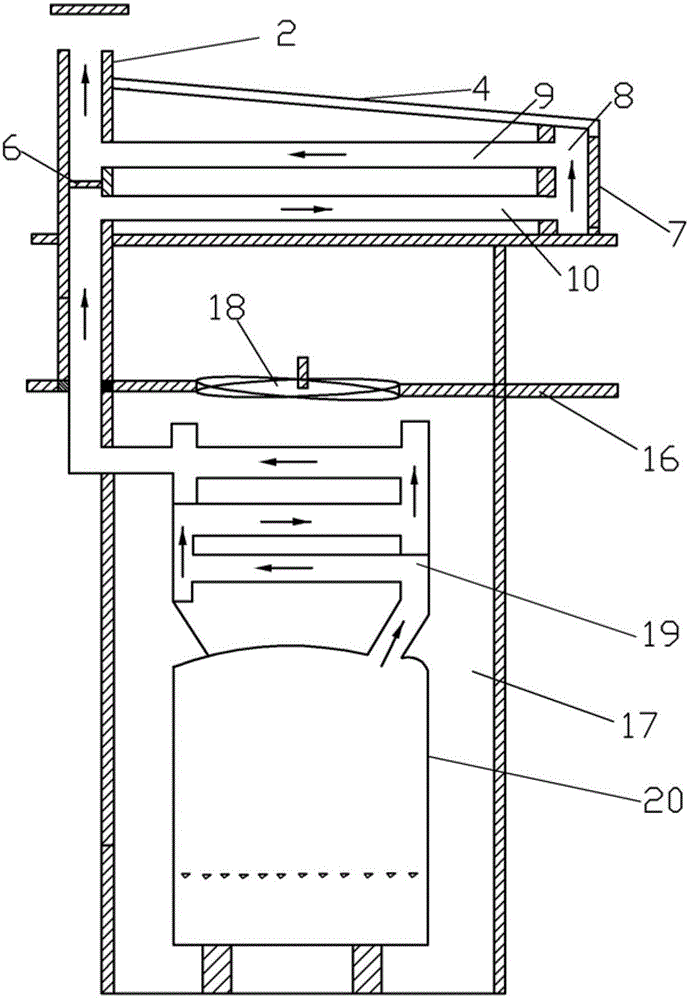

[0021] see Figure 1 ~ Figure 2 , the flue gas waste heat utilization device of the tobacco leaf intensive curing room, including a chimney 2, a heat exchange chamber 3, a smoke returning room 8, a connecting room 13 and a smoke returning room 8; the curing room includes a tobacco loading room 1 and a heating room 17; A heat insulating wall 11 is arranged between the heating chamber 17 and the smoke chamber 1; a roof 101 is provided on the top of the heating chamber 17 and the smoke chamber 1; Fan deck 16, described fan deck 16 extends to outside heating chamber 17; Furnace 20 is arranged inside described heating chamber 17, and heat exchanger 19 is arranged above described stove 20; On described fan deck 16 , a circulation blower 18 is fixed at a position directly above the heat exchanger 19; the fan plate 16 is located below the roof 101; on the upper surface of the roof 101, on the A heat exchange chamber 3 and a chimney 2 are arranged above the heating chamber 17; the smo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com