Resin composition

A technology of resin composition and compound, applied in the direction of adhesive types, adhesive additives, ester copolymer adhesives, etc. sexual difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0059] Hereinafter, examples of the present invention will be described, but the present invention is not limited to these.

[0060] (Preparation of resin composition)

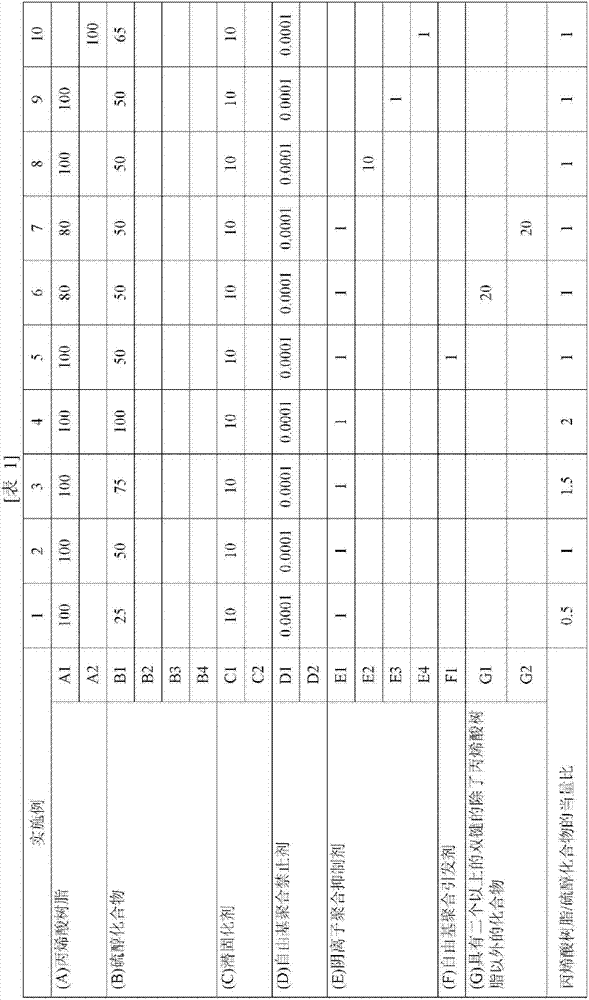

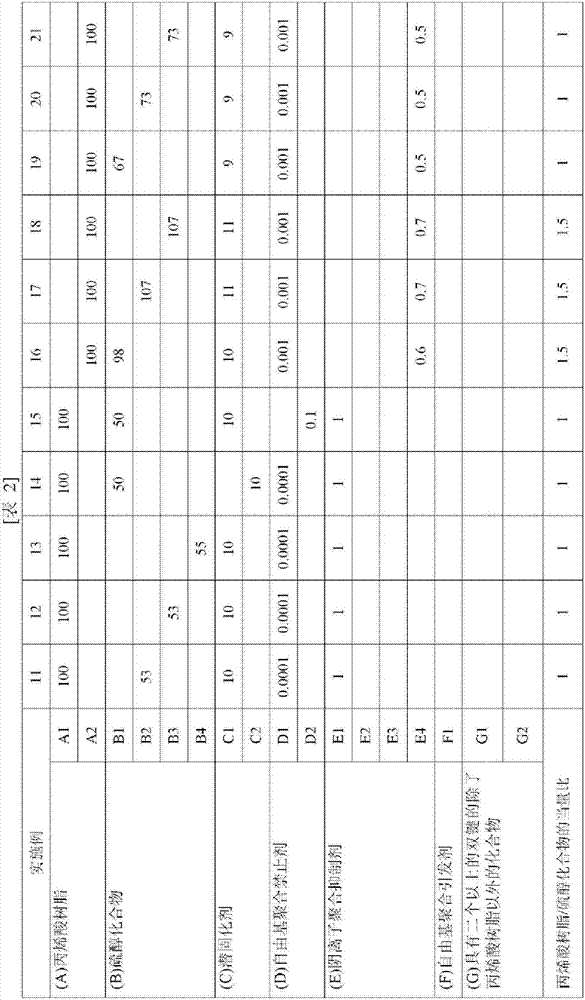

[0061] Each component was mixed in the compounding shown in Table 1, 2, and the resin composition in Examples 1-21 was prepared.

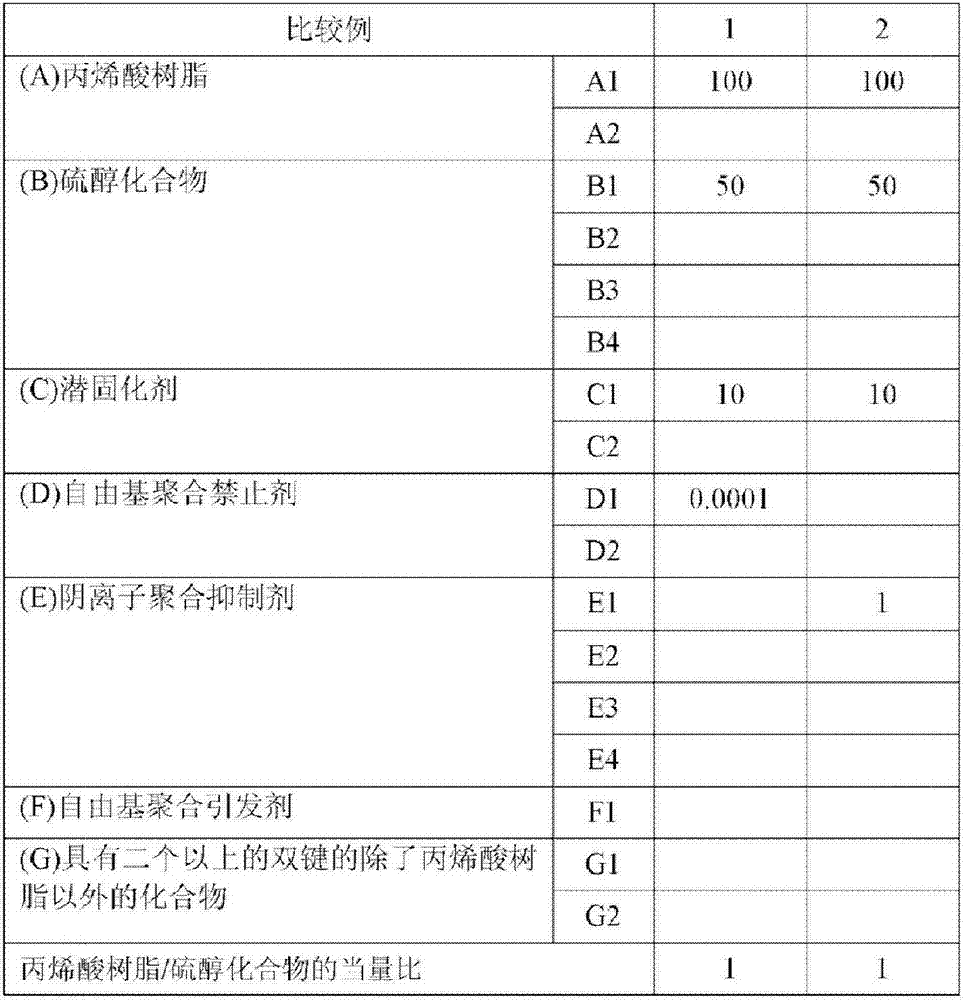

[0062] Each component was mixed in the compounding shown in Table 3, and the resin composition in Comparative Examples 1-2 was prepared.

[0063] In addition, in Tables 1-3, all the figures which show the compounding ratio of each component of (A)-(G) are shown by weight part.

[0064] In Tables 1-3, the specific substance name etc. of each component of (A)-(G) are as follows. In addition, some structural formulas of (A) to (G) are shown in the following [Chemical 1], [Chemical 2], [Chemical 3], [Chemical 4].

[0065] (A1) Acrylic resin 1: "EBECRYL810" manufactured by DAICEL-CYTEC Company, Ltd.

[0066] Polyester acrylate, weight average molecular weight about 1000, 4 functional ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com