Processing method of printed circuit board (PCB) and PCB

A processing method and technology for PCB boards, applied in the direction of secondary processing of printed circuits, etc., can solve the problems of poor tin surface quality, affecting the quality of PCB, and the effect of removing moisture is not obvious, so as to solve the problem of board edge delamination, Improve the problem of edge delamination and improve the effect of edge delamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

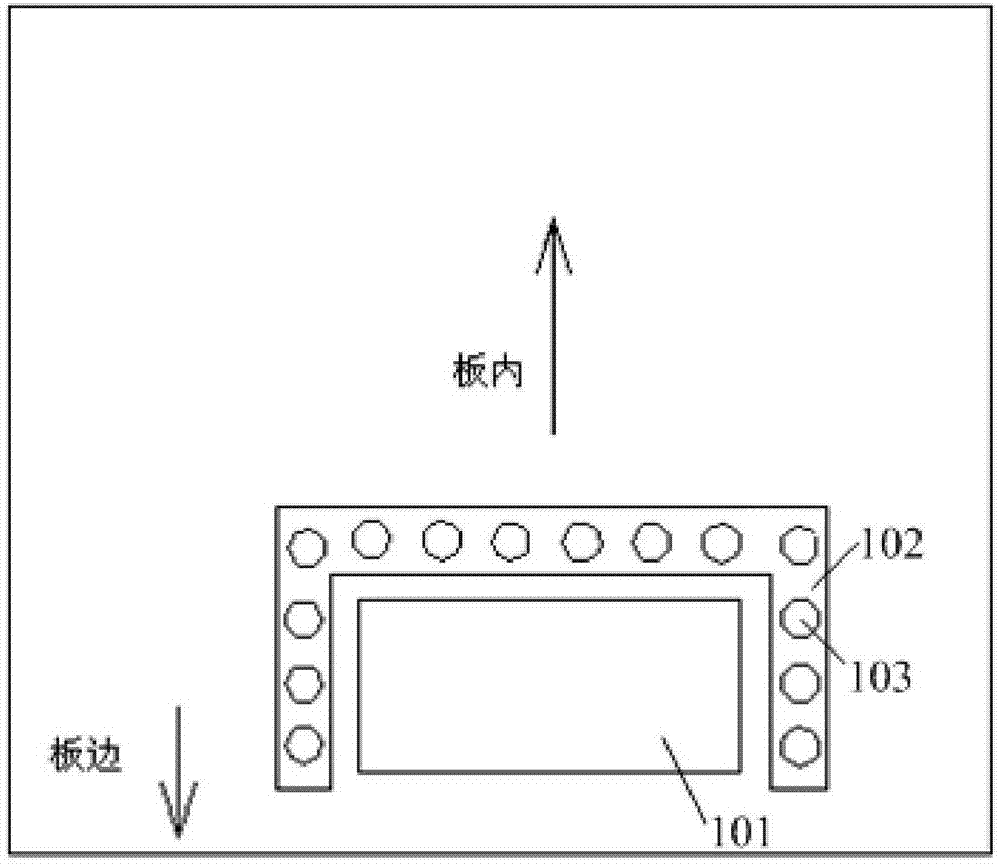

[0048] Using S1155 1.61 / 1 to make a double-sided panel with a total of 10PNL, the outer layer processing process is graphic transfer→graphic plating→etching→solder resist characters→baking→surface treatment→molding. The surface treatment process is tin spraying, and the tin spraying parameters are: temperature 260°C, tin immersion time 3s, air knife temperature 380°C. After the tin spraying is completed, inspect and evaluate the quality of the tin surface of the board; at the same time, visually inspect and analyze the edge of the PCB board to understand the delamination of the board edge.

Embodiment 2

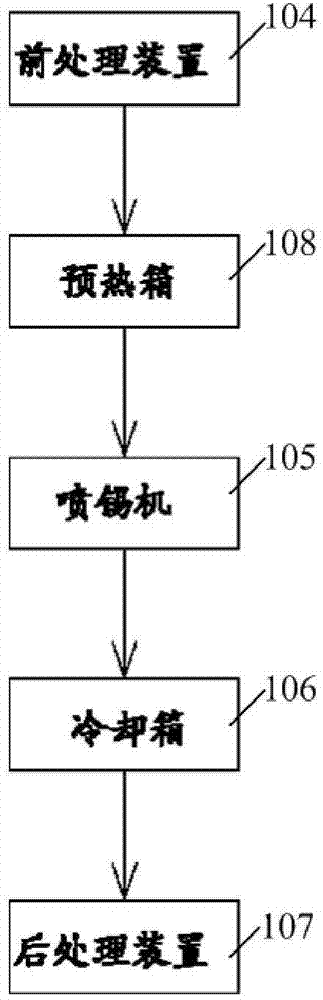

[0050] Using S11551.61 / 1 to make a double-sided panel with a total of 10PNL, the outer layer processing process is graphic transfer→graphic plating→etching→solder resist characters→baking→surface treatment→molding. The surface treatment process is tin spraying, and the tin spraying parameters are: temperature 240°C, tin immersion time 2s, air knife temperature 340°C. The baking process before HASL is: 150℃ / 2hr. After the tin spraying is completed, inspect and evaluate the quality of the tin surface of the board; at the same time, visually inspect and analyze the edge of the PCB board to understand the delamination of the board edge.

Embodiment 3

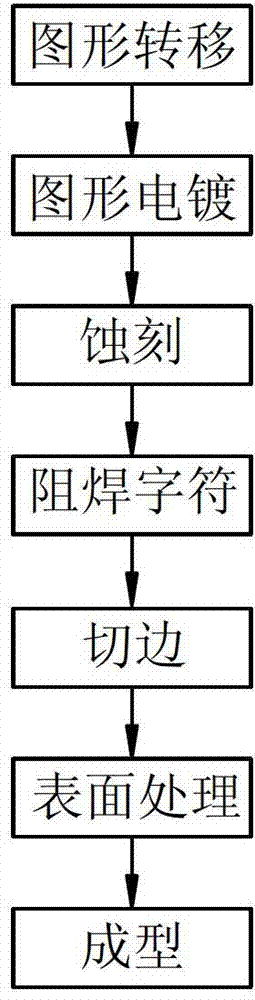

[0052] Use S11551.61 / 1 to make a double-sided board with a total of 10PNL, such as image 3 As shown, the outer layer processing technology is graphic transfer→graphic electroplating→etching→solder resist characters→edge trimming process→surface treatment→molding. The surface treatment process is tin spraying, and the tin spraying parameters are: temperature 260°C, tin immersion time 3s, air knife temperature 380°C. After the tin spraying is completed, inspect and evaluate the quality of the tin surface of the board; at the same time, visually inspect and analyze the edge of the PCB board to understand the delamination of the board edge.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com