Multifunctional mobile heat storing and discharging method and mobile heat supplying device

A heat supply device and transportation device technology, applied in the field of multifunctional mobile heat storage and release methods and mobile heat supply devices, can solve the problems of low transportation cost, small heat storage capacity, and large equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

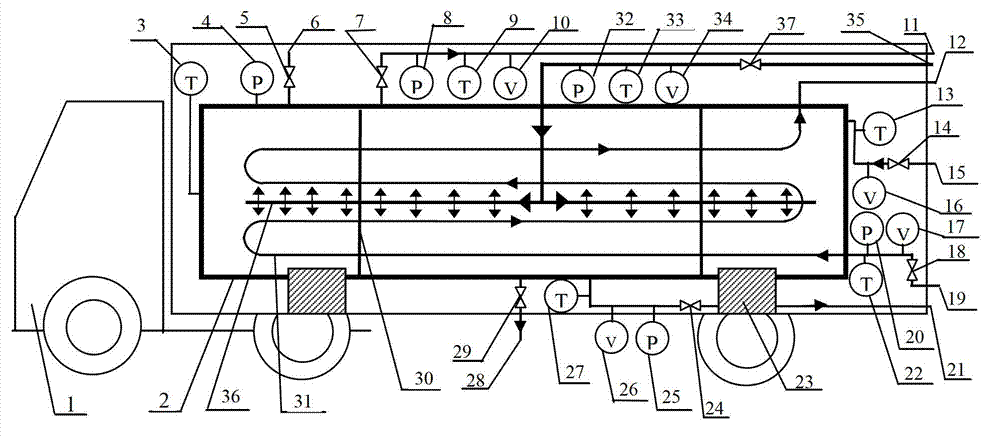

[0030] combine figure 1 , a mobile heating device, comprising a water storage tank 2 and a truck 1, the water storage tank 2 is a cylinder or an ellipsoid, made of carbon steel or stainless steel, and the outside of the water storage tank 2 is laid with a thickness of 10 cm layer of insulating material above. The water storage tank 2 is fixed on the truck 1 through the base 23, and the inside of the water storage tank 2 is provided with a heat exchange tube 31, and the inlet and outlet 12 of the heat exchange tube 31 are located outside the water storage tank 2. The inside of the water storage tank 2 is also provided with a distribution pipe 36, which is evenly opened with a plurality of nozzles, and the distribution pipe 36 is connected with an injection pipe 35 for accessing steam or hot water. The water storage tank 2 is connected with a cold water injection pipe 15, the water storage tank 2 is connected with a first pressure gauge 4 and a first temperature gauge 3, and is...

Embodiment 2

[0036] Embodiment 1 The heat storage and discharge method of the mobile heat supply device, comprising the following steps:

[0037](1) Heat storage process: inject cold water into the water storage tank 2, the liquid level of the cold water is higher than the heat exchange tube 31 and the distribution tube 36 inside the water storage tank 2, and the high temperature fluid is passed into the heat exchange tube 31 and the water storage tank The cold water in the tank 2 is subjected to indirect heat exchange, and high-temperature and high-pressure steam or hot water is injected into the cold water through the distribution pipe 36 for direct mixed heat exchange. Inject the high-temperature fluid into the medium, stop injecting high-temperature and high-pressure steam or hot water, and the heat storage of the water storage tank 2 ends;

[0038] (2) Heat release process: the steam outlet pipe 11 at the top of the water storage tank 2 releases steam at different temperatures and pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com